Page 18

WARNING

Possible equipment damage.

Avoid deep vacuum operation. Do not use compressors

to evacuate a system. Extremely low vacuum can cause

internal arcing and compressor failure. Damage caused

by deep vacuum operation will void warranty.

IMPORTANT

Use a thermocouple or thermistor electronic vacuum

gauge that is calibrated in microns. Use an instrument

capable of accurately measuring down to 50 microns.

Evacuating the system of non-condensables is critical for

proper operation of the unit. Non-condensables are de-

ned as any gas that will not condense under tempera-

tures and pressures present during operation of an air

conditioning system. Non-condensables and water suc-

tion combine with refrigerant to produce substances that

corrode copper piping and compressor parts.

NOTE - Remove cores from service valves if not already

done.

1 - Connect an HFC-410A manifold gauge set as

illustrated in gure 5.

2 - Open both manifold valves and start the vacuum

pump.

3 - Evacuate the line set and indoor unit to an absolute

pressure of 23,000 microns (29 inches of mercury).

NOTE - During the early stages of evacuation, it is desir-

able to close the manifold gauge valve at least once to

determine if there is a rapid rise in pressure this indicates

a relatively large leak. If this occurs, repeat the leak test-

ing procedure.

NOTE - The term absolute pressure means the total ac-

tual pressure within a given volume or system, above the

absolute zero of pressure. Absolute pressure in a vacuum

is equal to atmospheric pressure minus vacuum pressure.

4 - When the absolute pressure reaches 23,000

microns (29 inches of mercury), close the manifold

gauge valves, turn off the vacuum pump and

disconnect the manifold gauge center port hose

from vacuum pump. Attach the manifold center

port hose to a dry nitrogen cylinder with pressure

regulator set to 150 psig (1034 kPa) and purge the

hose. Open the manifold gauge valves to break the

vacuum in the line set and indoor unit. Close the

manifold gauge valves.

5 - Shut off the dry nitrogen cylinder and remove the

manifold gauge hose from the cylinder. Open the

manifold gauge valves to release dry nitrogen from

the line set and indoor unit.

6 - Reconnect the manifold gauge to vacuum pump,

turn pump on, and continue to evacuate line set and

indoor unit until the absolute pressure does not rise

above 500 microns within a 20-minute period after

shutting off vacuum pump and closing the manifold

gauge valves.

7 - When the absolute pressure requirement above has

been met, disconnect the manifold hose from the

vacuum pump and connect it to an upright cylinder

of HFC-410A refrigerant. Open the manifold gauge

valve pressure line set to break vacuum with 2 to

5 psi.

8 - Perform the following:

A - Close manifold gauge valves

B - Shut off HFC-410A cylinder

C - Reinstall service valve cores by removing manifold

hose from service valve. Quickly install cores

with core tool while maintaining a positive system

pressure.

D - Replace the stem caps and secure nger tight, then

tighten an additional one-sixth (1/6) of a turn as

illustrated in gure 2.

C-Charging

ELS units have a factory holding charge of 2 pounds of

HFC-410A in each circuit. Additional refrigerant will need

to be added during installation (table 3).

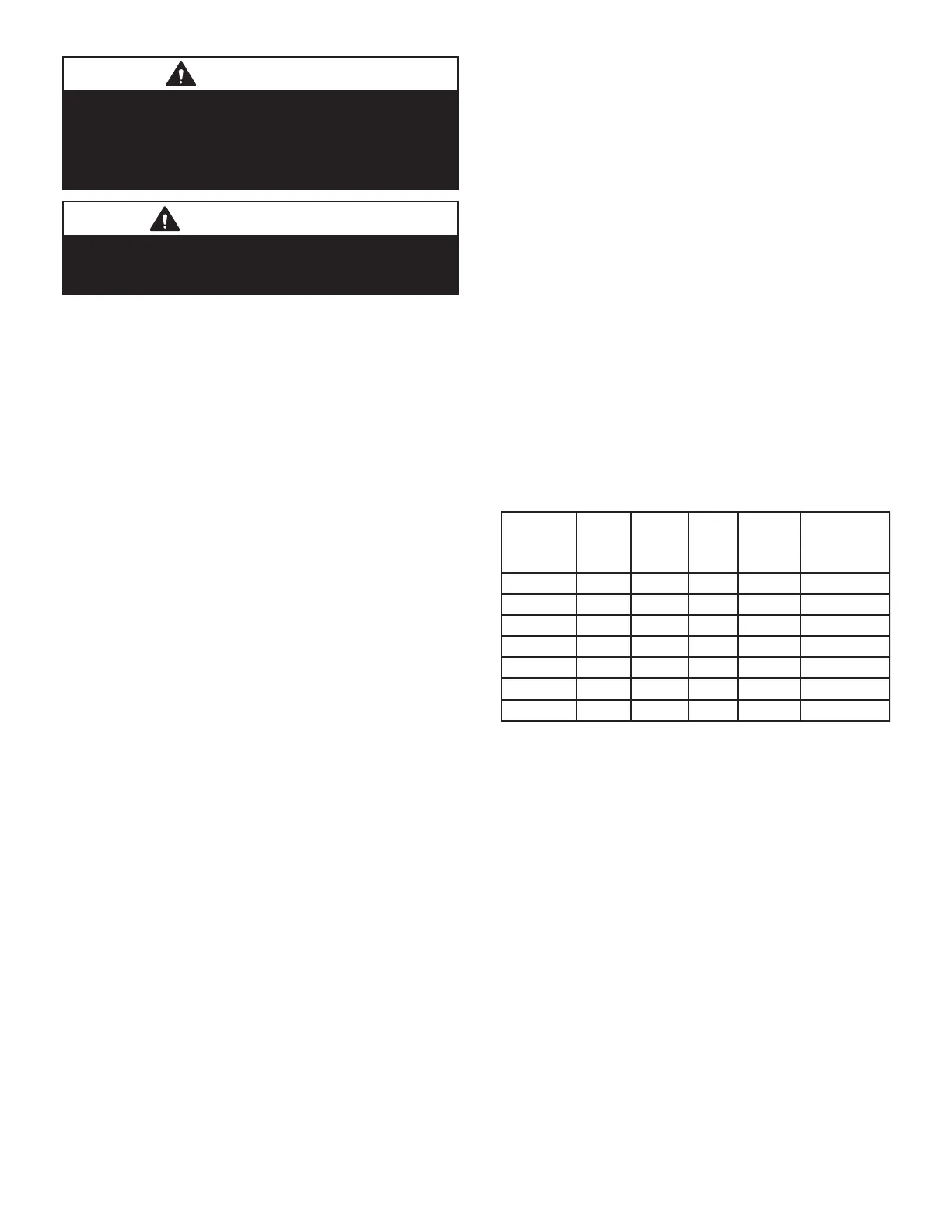

TABLE 3

Adding Refrigerant

Models

Stage 1

lbs

for 25ft

line set

Stage 2

lbs

for 25ft

line set

Liq.

Line

Dia.

Suction

Line

Dia.

Ounces

Adjustment

per foot of

line set

1

ELS072S4S 18.5N/A 3/8 1-1/8 0.7

ELS090S4S 21.75N/A 5/8 1-1/8 1.7

ELS120S4S23N/A 5/8 1-1/8 1.7

ELS120S4D12123/8 1-1/8 0.7

ELS150S4D15 15.53/8 1-1/8 0.7

ELS180S4D 23.75 23.55/8 1-1/8 1.7

ELS240S4D 22.5 23.55/8 1-1/8 1.7

1

If line set length is greater than 25 feet, add this amount

to each circuit. If line set is less than 25 feet, subtract this

amount from each circuit. Refer to Lennox Refrigerant

Piping Design and Fabrication Guidelines for more infor-

mation.

NOTE - Refrigerant line sets longer than 200 feet (60 me-

ters) are not recommended. For assistance contact Len-

nox Application Department.

To check the charge, use the following procedure:

1 - Attach gauge manifolds and operate unit in cooling

mode until system stabilizes (approximately ve

minutes). Make sure outdoor air dampers are

closed.

2 - Use a thermometer to accurately measure the

outdoor ambient temperature.

3 - Apply the outdoor temperature to tables 5 and 6 to

determine normal operating pressures.

Loading...

Loading...