IOM – FLEXY II – 1007 – E Page 18

When the f ram e is c o r r e ct ly p o s it i o n e d , i t is ess ential t o s ec ure t he as s embly wit h a disc onnect ed s t it c hed welded s eam (20 t o

30mm every 200mm ) a l o n g t he out s ide or by us ing an alt ernat iv e m et h o d

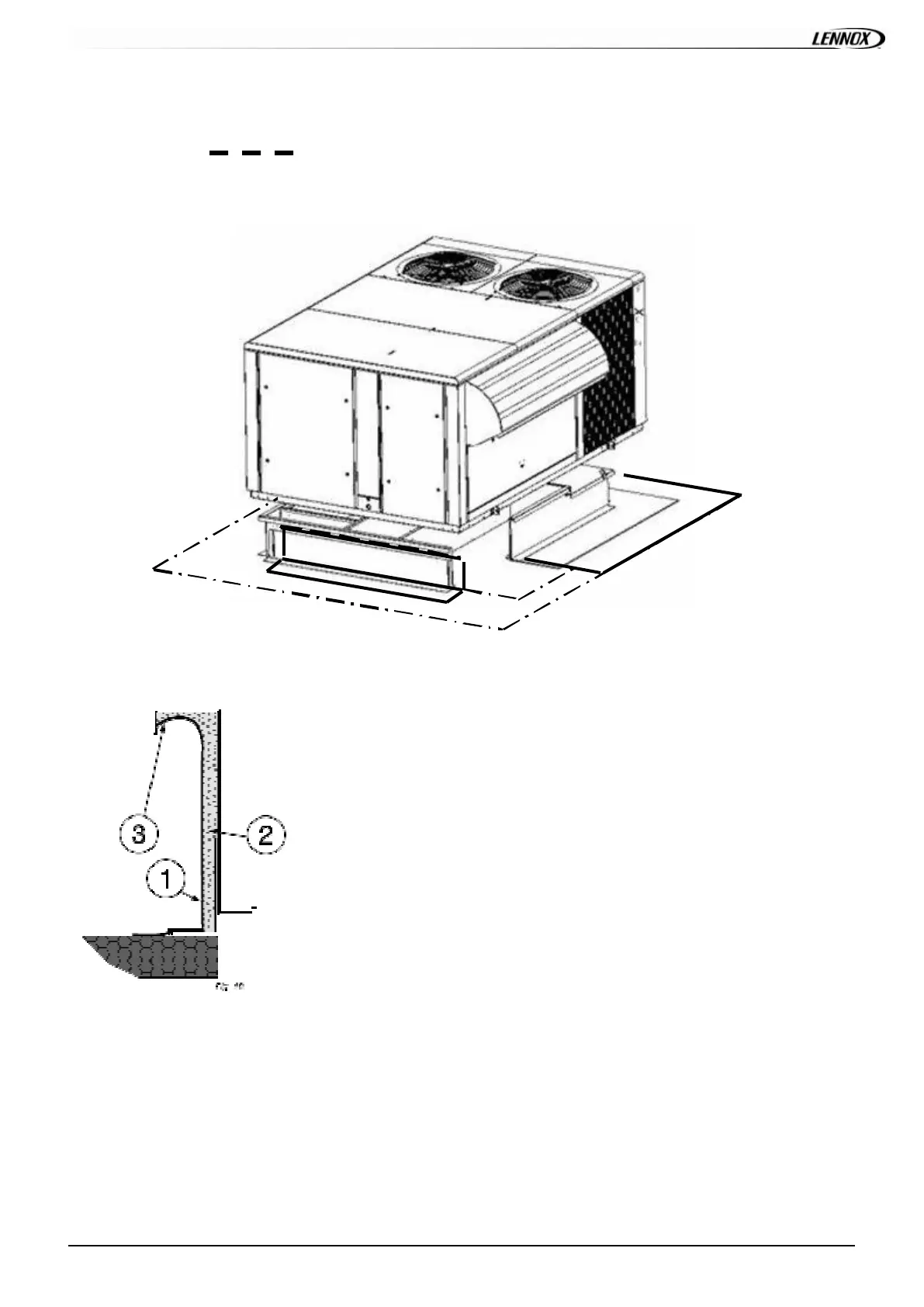

CURBING AND FL AS HING

Outside of frame must be insulated with rigid type insulation;

We recommend a minimum of 20 mm t hick ins ulat ion (2-figure 7).

Check that the insulation is continuous, counter f lash and seal around the

frame

as shown in (1-figure 7).

CAUTION: To be effective, the upstream must end below the drop edge (3 - figure

7).

Where pipes and electrical conduits extend through the roof, flashing must be

conformed to local codes of practice.

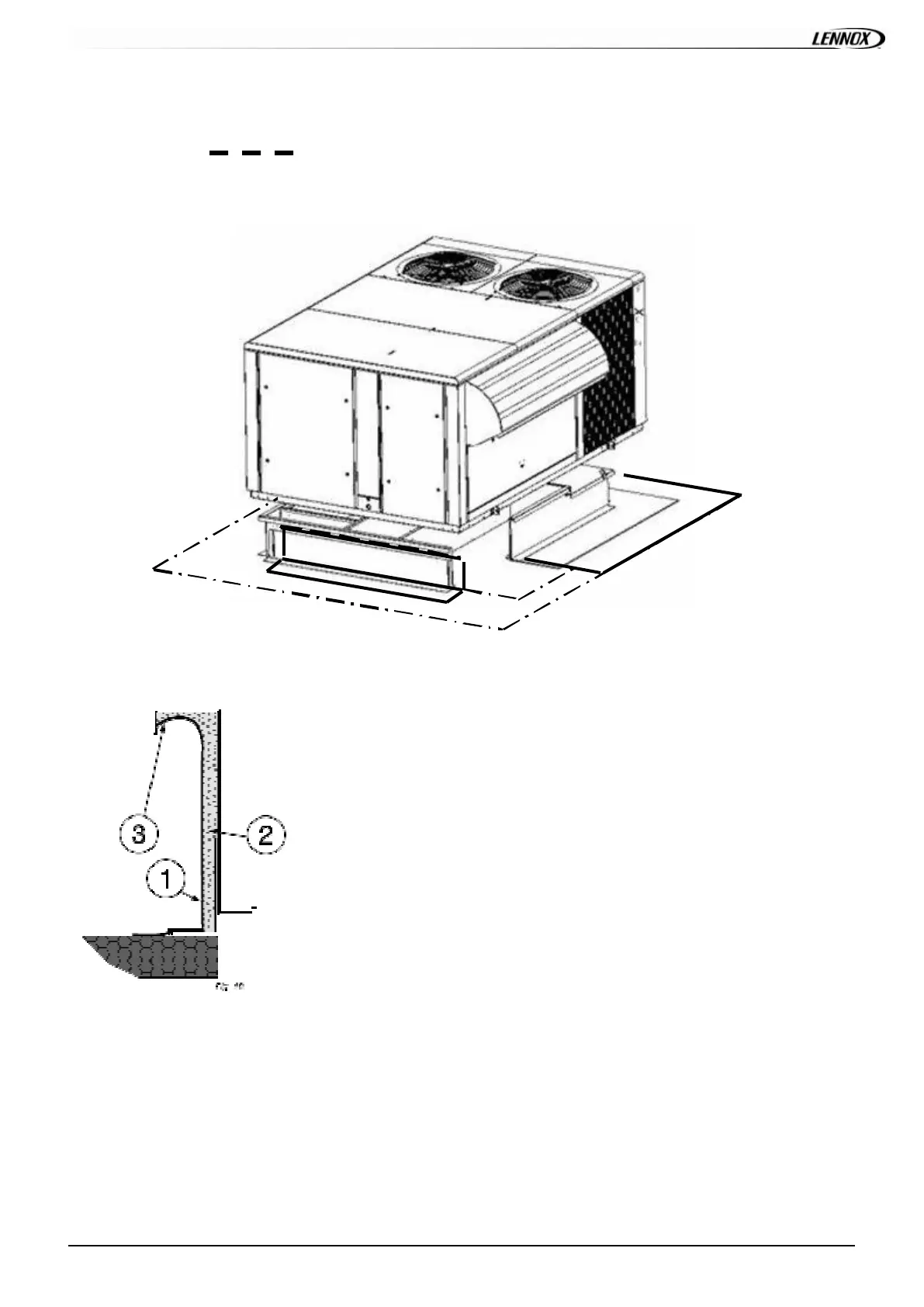

Bef ore installing the equipment, make sure that seals are not damaged and check that the unit is secured to the mounting

frame. Once in position, the bottom of the equipment must be horizontal.

The installer m ust c om ply wit h loc al aut hority standards and specifications.

RECOMMENDATIONS FOR DUCTS CONNECTIONS

Some rules must be complied with for the connections between ducts and unit done on site.

INSTALLATION ON A ROOFMOUNTING FRAM E

Loading...

Loading...