IOM – FLEXY II – 1007 – E Page 33

BELT TEN SI ON

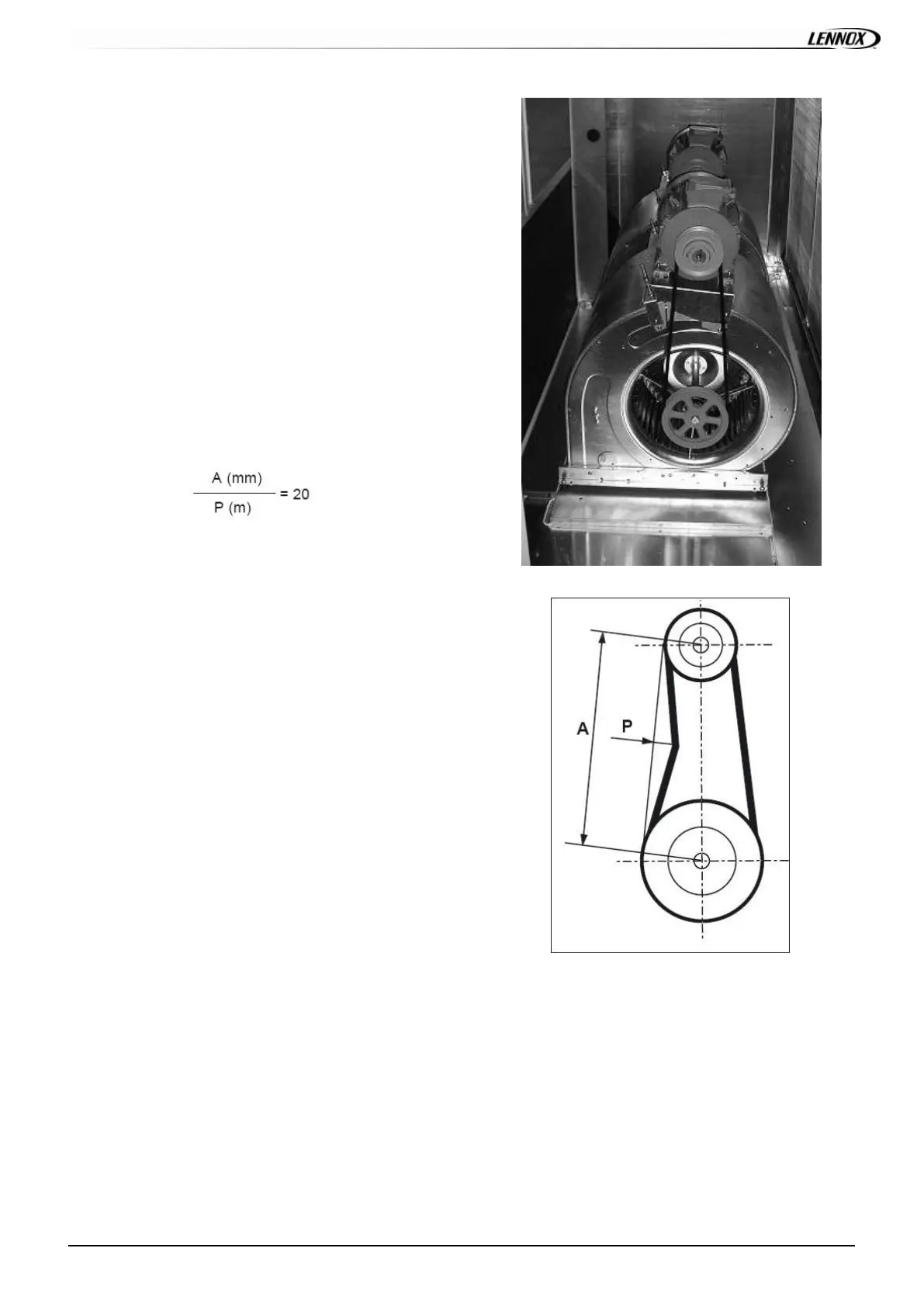

On deliv ery, the driv e belts are new and correctly

tensioned. After the first 50 operating hours check and

adjust the tension. 80% of the total elongation of belts is

generally produced during the first 15 hours of operation.

Bef ore adjusting the tension, make sure that the pulleys

are correctly aligned.

To t ension t he belt, set t he height of m ot or s upport plat e

by moving the plate adjustment screws.

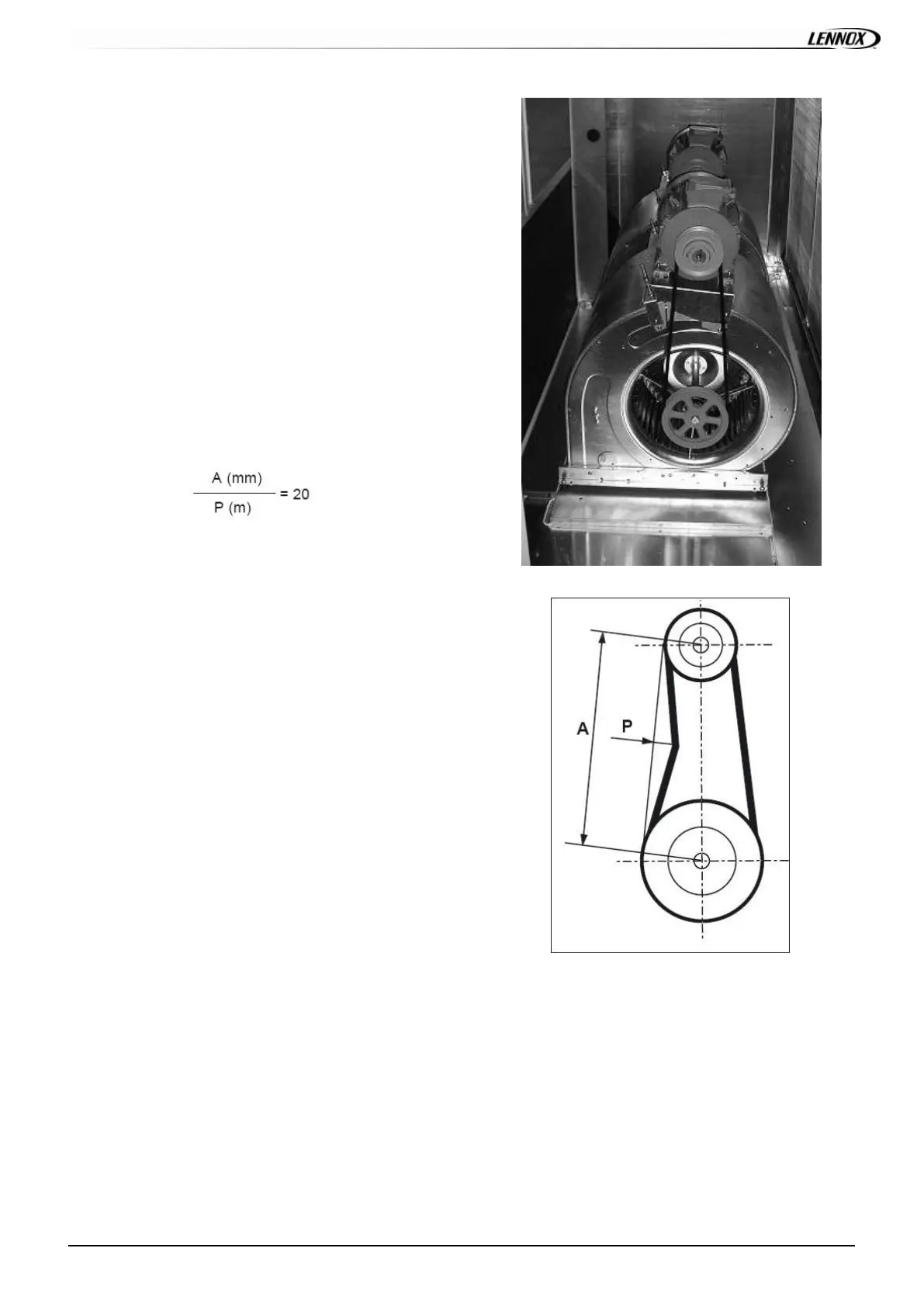

The rec ommended def lec t ion is 20 m m per met er f rom

centre to centre.

Check that according to the diagram below (f igure 12), the

following ratio remains the same.

The belt s s hould alway s be replaced when:

- The disk is set to maximum,

- The belt rubber is worn or the wire is visible.

Replacement belts must have the same rated size as the

ones they are replacing. If a transmission system has

several belts, they must all be f rom the same

NOTE:

An under-tensioned belt will slip, heat and wear

prematurely. On the other hand, if a belt is over-tensioned,

the pressure on the bearings will cause them to over-heat

and wear prematurely. Incorrect alignment will also cause

the belts to wear prematurely.

Loading...

Loading...