Page 32

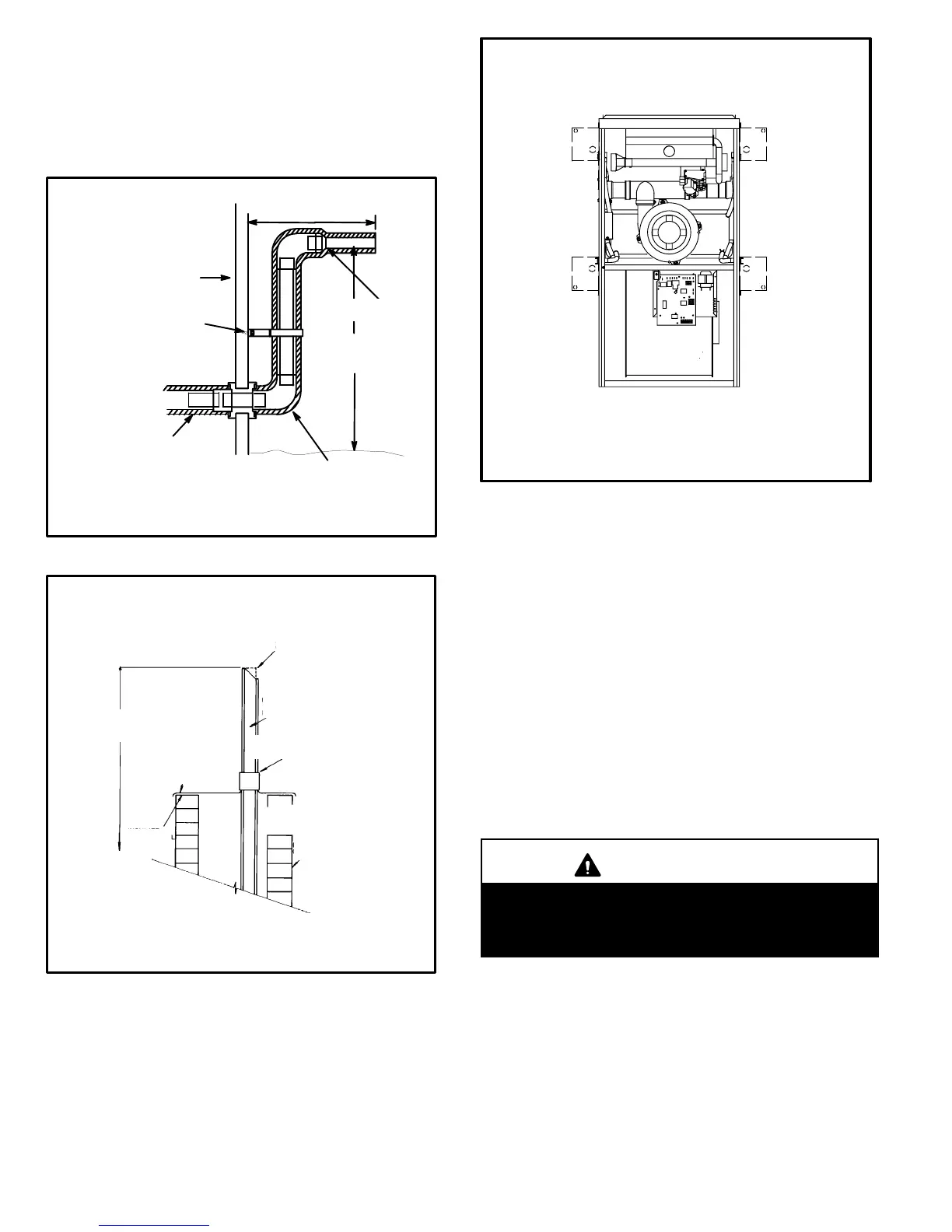

3. If exhaust piping must be run up a side wall to position

above snow accumulation or other obstructions, piping

must be supported every 3 feet (.9m) as shown in fig-

ure 18. Refer to figure 38 for proper piping method.

When exhaust piping must be run up an outside wall,

any reduction in exhaust pipe size must be done after

the final elbow.

FIGURE 38

12" (305) ABOVE

AVERAGE SNOW

ACCUMULATION

UNCONDITIONED

SPACE

1/2" (13) FOAM

INSULATION

1/2" (13) FOAM

INSULATION IN

UNCONDITIONED

SPACE

PROVIDE SUPPORT

FOR EXHAUST LINES

EVERY 36" (914)

OUTSIDE WALL

Inches(mm)

SIDE VIEW

NON−DIRECT VENT WALL RING TERMINATION

(15F74)

12" (305) Max. for 2" (51)

Unless Supported

SIZE TERMINATION

PIPE PER TABLE 15.

FIELD−PROVIDED

REDUCER MAY BE

REQUIRED TO

ADAPT LARGER

VENT PIPE SIZE TO

TERMINATION

NOTE − Do not discharge exhaust gases directly into any chimney or vent stack. If ver-

tical discharge through an existing unused chimney or stack is required, insert piping

inside chimney until the pipe open end is above top of chimney and terminate as illus-

trated. In any exterior portion of chimney, the exhaust vent must be insulated.

FIGURE 39

3" − 8"

(76mm−

203mm)

3" − 8"

(76mm−

203mm)

MINIMUM

12" (304mm)

ABOVE AVERAGE

SNOW ACCUMULATION

STRAIGHT−CUT OR

ANGLE−CUT IN DIRECTION

OF ROOF SLOPE

EXHAUST VENT

1/2" (13mm)

WEATHERPROOF

INSULATION

SHOULDER OF FITTINGS

PROVIDE SUPPORT

OF PIPE ON TOP PLATE

EXTERIOR

PORTION OF

CHIMNEY

INSULATE

TO FORM

SEAL

SHEET

METAL TOP

PLATE

MINIMUM 12"

(305mm) ABOVE

AVERAGE SNOW

ACCUMULATION

SIZE TERMINATION

PIPE PER TABLE 15.

G51MP NON−DIRECT VENT APPLICATION

USING EXISTING CHIMNEY

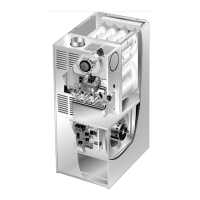

Condensate Piping

This unit is designed for either right- or left-side exit of con-

densate piping in either upflow or downflow applications;

however, it must be installed on the same side of the unit as

the exhaust piping . In horizontal applications, the conden-

sate trap should extend below the unit. A 5−1/2" service

clearance is required for the condensate trap. Refer to fig-

ure 40 for condensate trap locations.

FIGURE 40

CONDENSATE TRAP LOCATIONS

(Unit shown in upflow position)

Horizontal

left and

optional

downflow

Horizontal

right and

optional

downflow

Optional

upflow

Optional

upflow

NOTE − In upflow applications where side return

air filter is installed on same side as the conden-

sate trap, filter rack must be installed beyond

condensate trap to avoid interference.

1 − Determine which side condensate piping will exit the

unit. Remove plugs from the condensate collar at the

appropriate location on the side of the unit.

NOTE − The condensate trap is factory−shipped with

two rubber O−rings and two rubber clean−out caps

installed. Check to make sure that these items are in

place before installing the trap assembly.

2 − Install condensate trap onto the condensate collar. Use

provided HI/LO screws to secure two upper flanges of

the trap to the collar. Use provided sheet metal screw to

secure bottom trap flange to side of unit. See figure 41.

NOTE − In upflow and downflow applications, condensate

trap must be installed on the same side as the exhaust pip-

ing. The optional Condensate Trap Alternate Location Kit #

7620M" is available for those installations where the trap

cannot be mounted on the same side as the exhaust.

CAUTION

DO NOT use a power driver to tighten screws which

secure condensate trap to cabinet. Screws should be

hand−tightened using a screw driver to avoid the pos-

sibility of damage to the trap assembly.

3 − Glue the field−provided coupling or pipe to the trap.

Install a tee and vent pipe near the trap.

NOTE − The condensate trap drain stubs (both sides)

have an outer diameter which will accept a standard

3/4" PVC coupling. The inner diameter of each stub will

accept standard 1/2" diameter PVC pipe.

NOTE − Vinyl tubing may be used for condensate drain.

Tubing must be 1−1/4" OD X 1" ID and should be at-

tached to the drain stubs on the trap using a hose

clamp.

Loading...

Loading...