Page 33

The condensing unit will be in low speed and the in-

door blower will be operating at a speed equivalent to

the setting of the zone 1 CFM jumper. It may take the

blower 60 to 90 seconds to reach this speed.

3 To check the amount of air being delivered to each

zone, cycle through each zone to confirm that damp-

ers are working correctly and that the amount of air to

each zone is adequate. Keep in mind that the zone

CFM jumpers affect the amount of air delivered in both

cooling and heating modes.

Central Control

1 Press the cooling switch and central switch on the sys-

tem control panel. See figure 28.

The amber LEDs on the cooling switch and the fan

auto switch of the system control panel will be lit.

If heat pump system, Output LED O on (reversing

valve energized).

2 Initiate a cooling demand from master thermostat.

LEDs Y1 and O1 on. (Cool input demand ).

Output LED G on.(Blower on)

LEDs 1DZ through 4DZ off. (All dampers open)

Condensing unit will operate in low speed and out

put LED Y1 and O1 are lit. (compressor on)

Indoor blower will operate at a speed equivalent to

the sum of all zone CFM jumper settings. It may

take the blower 60 to 90 seconds to reach this

speed.

3 Remove all demands.

F−System Off (All Systems)

1− Depress the system off switch on the system control

panel. See figure 28.

The amber LED on the system off switch on the

system control panel will be lit.

2− In this mode, The entire system is shut down and will

not respond to any demands. However, the fan will op-

erate if the fan on switch is selected. It may take the

blower 60 to 90 seconds to reach full speed.

G−Discharge Probe Checkout (All Systems)

It is difficult to checkout the discharge air temperature

probe directly. The temperature of the airstream corre-

sponds to a milliamp signal which passes through the

probe. This signal is not constant and cannot be measured

because the control center samples" the probe once ev-

ery 10 seconds. Each temperature sampling lasts only a

fraction of a second.

The control center is well equipped to monitor the opera-

tion of the probe and determine if a failure has occurred.

The probe should be considered an integral (but replace-

able) part of the control center. The control center will indi-

cate if the probe is operating improperly and needs to be

replaced.

Although it is hard to checkout the probe, it is easy to un-

derstand the purpose of the probe and to observe its op-

eration. Simply observing the probes operation will help

determine if it is operating properly.

The discharge air temperature probe serves several pur-

poses:

1 In cooling systems (and heat pump systems in cooling

mode) the probe varies the speed of the compressor

from high to low to off in order to maintain a constant

discharge air temperature and prevent coil freezing.

See table 5.

2 In gas heating systems, it is responsible for increasing

the speed of the blower to the setting of the CFM jump-

ers after the heat exchanger has warmed up to about

100F.

3 In heat pump systems operating in the heating mode,

the probe varies compressor speed and stages of aux-

iliary heat in order to maintain a constant discharge air

temperature. See table 6.

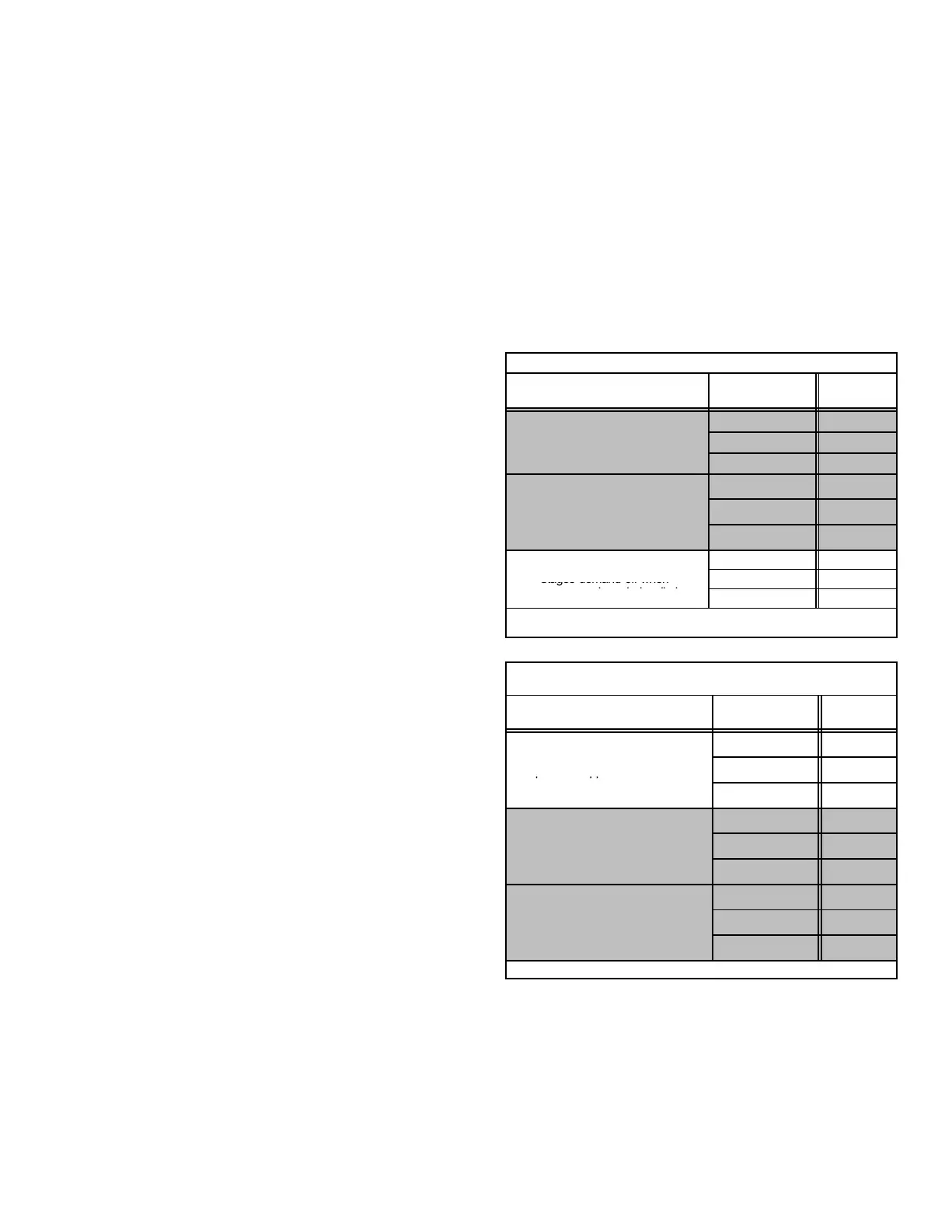

Table 5

Discharge Air Temperature Probe: Cooling Temperatures

Probe Function

response

Discharge Air

Temp." Jumper

Setpoint

Degrees F

High Limit

C+ 70

Shifts compressor to high speed

when temperature rises above

Off 65

w

en

empera

ure r

ses a

ove

limit.

C− 60

Low Limit

Tries to maintain this temperature

C+ 63

Tries to maintain this temperature.

Shifts compressor to low speed

when temperature drops below

Off 58

when temperature drops below

low limit.

C− 53

C+ 45

Stages demand off when

Off 45

temperature drops below limit.

C− 45

Shaded area indicates normal operating range.

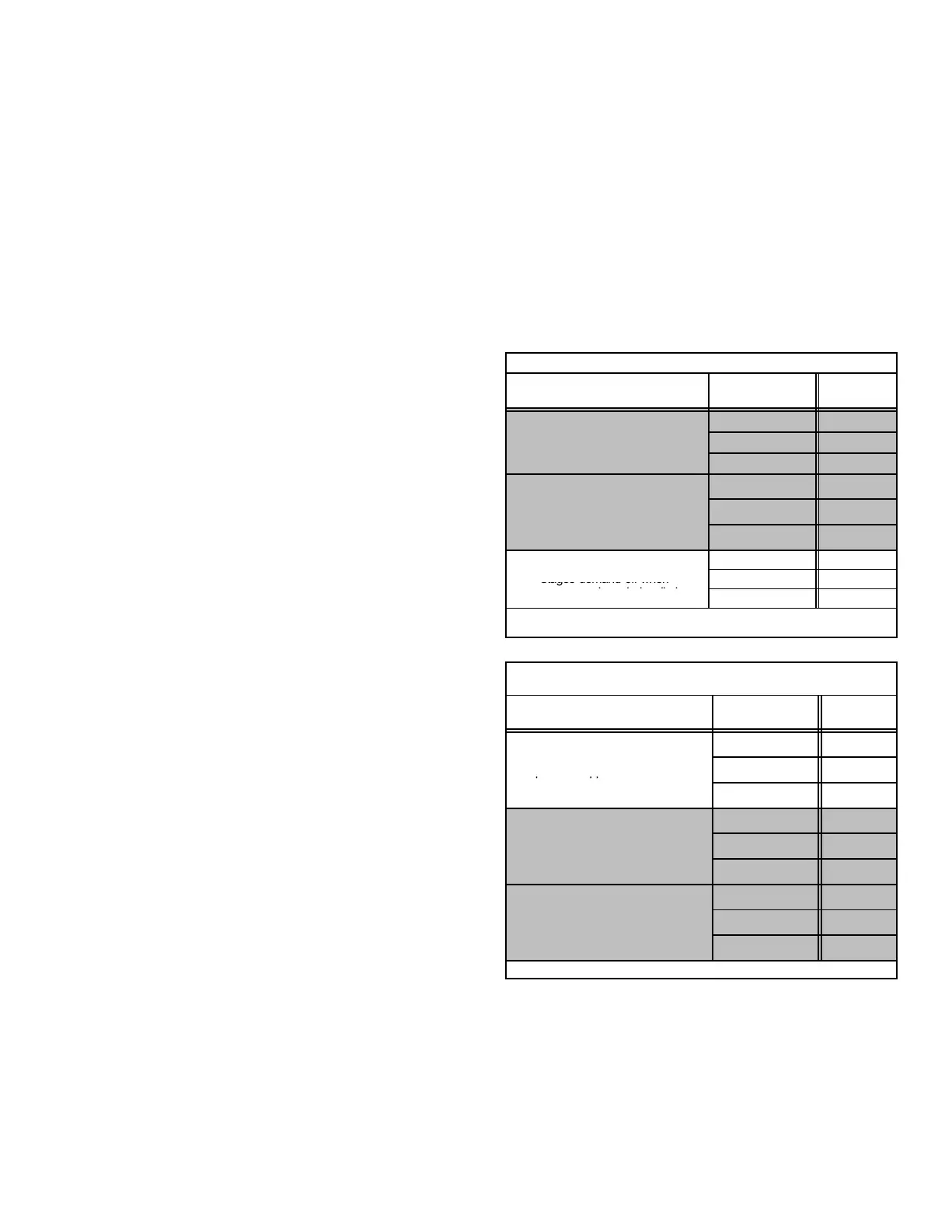

Table 6

Discharge Air Temperature Probe: Heating Temperatures

(Heat pump and FM21 systems only)

Probe Function

response

Discharge Air

Temp." Jumper

Setpoint

Degrees F

Safety Limit

Electric Heat: Turns Off Output When

H+ 135

Electric Heat: Turns Off Output When

Temperature Approaches Limit. Heat

Off 130

Pump: Turns Off Output When Tem-

perature Crosses Limit.

H− 125

High Limit

H+ 125

Tries to maintain

this temperature. Shifts compres-

sor to low speed when temperature

Off 120

sor to low speed when temperature

rises above high limit.

H− 115

Low Limit

Electric Heat: turns off output when

H+ 105

Electric Heat: turns o

output when

temperature approaches . Limit. Heat

Pump: turns off output when tem

Off 100

Pump: turns off output when tem-

perature crosses limit.

H− 95

Shaded area indicates normal operating range.

Loading...

Loading...