Loading...

Loading...

Do you have a question about the Lennox LCA060 and is the answer not in the manual?

| Refrigerant Type | R-410A |

|---|---|

| Phase | 1 |

| SEER | 16 |

| SEER Rating | 16 |

| Voltage (V) | 208/230 |

Details components within the unit's control box, including switches, transformers, and relays.

Covers compressors, capacitors, switches, and heaters related to the cooling system.

Explains blower types, housing access, and related components like motors and terminals.

Describes gas heat components like heat exchangers, burners, ignition controls, and gas valves.

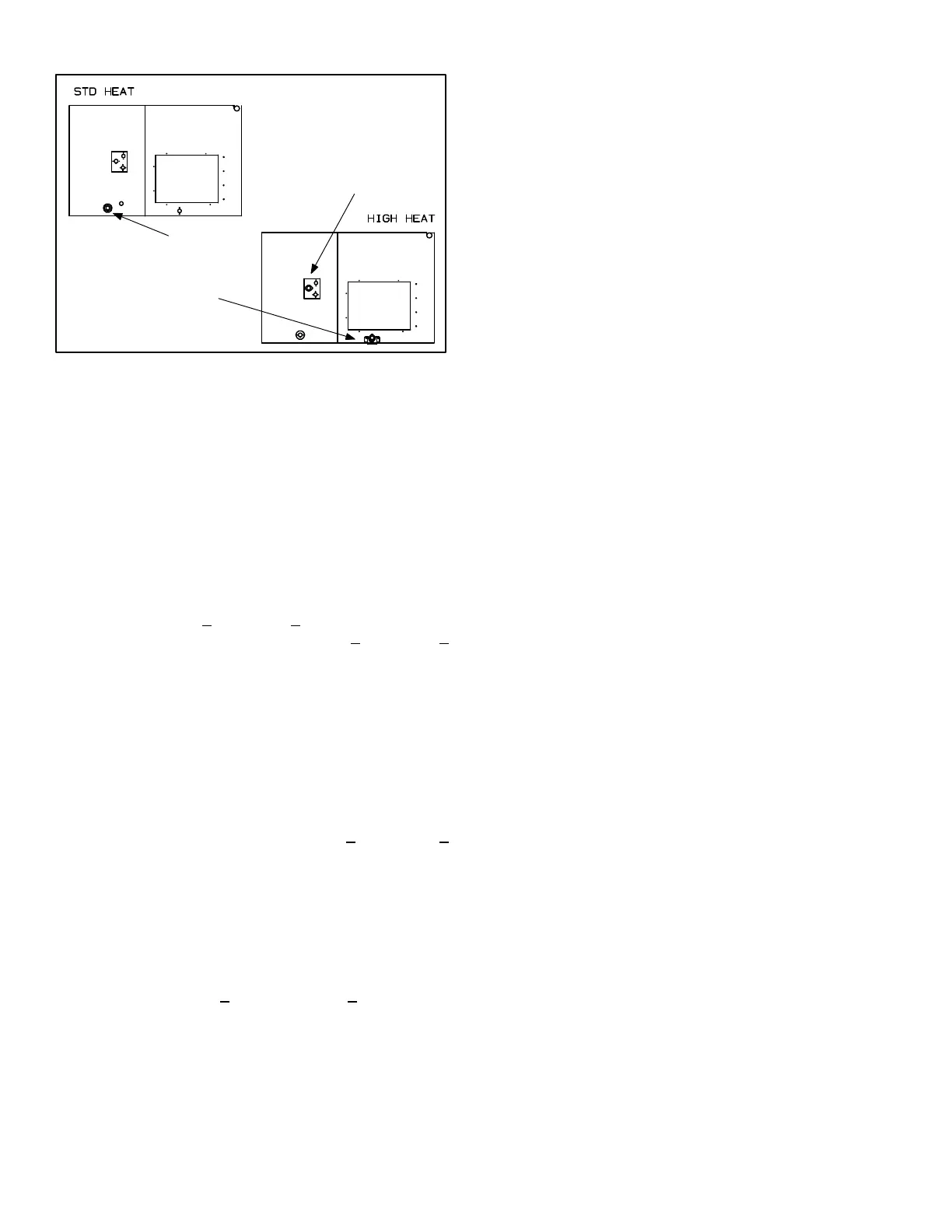

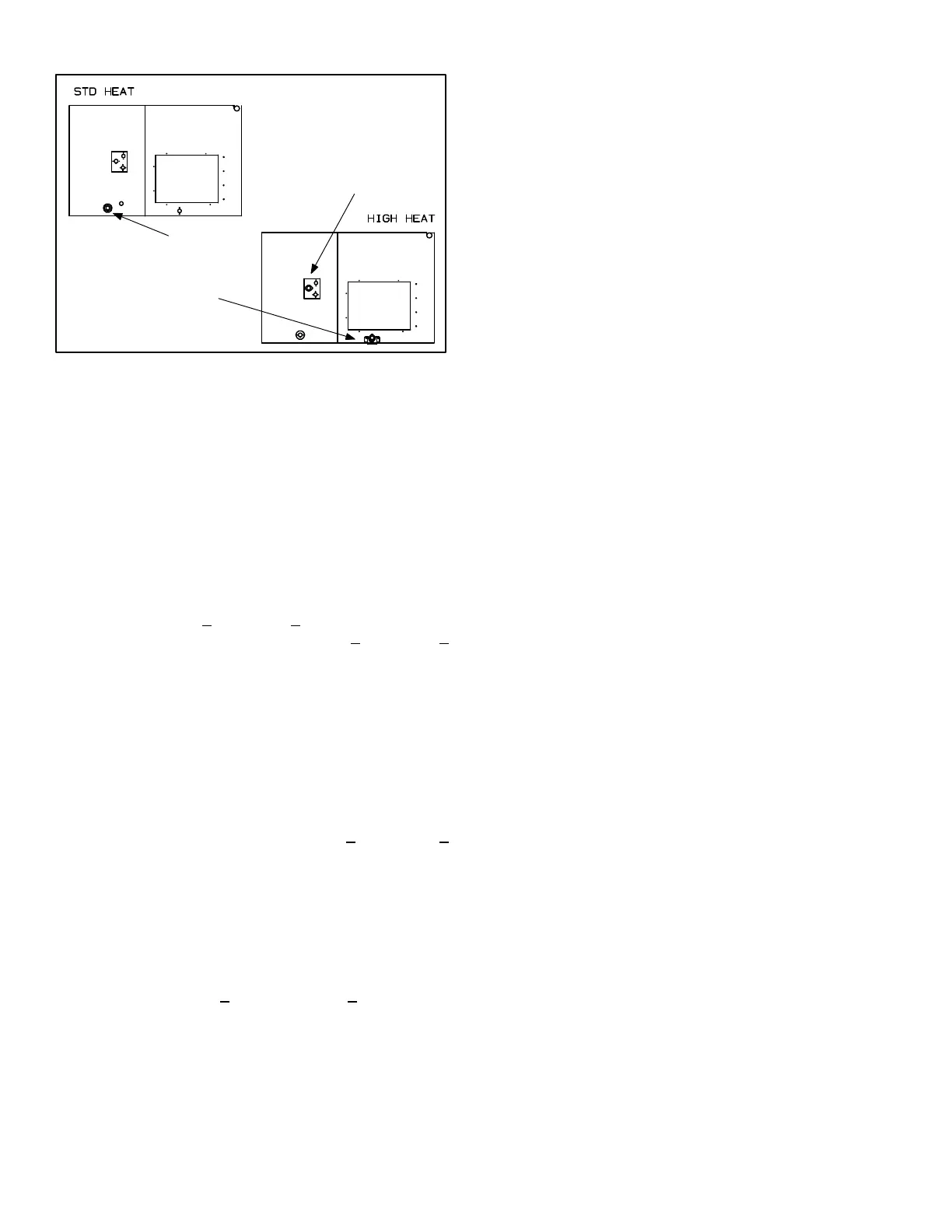

Details contactors, heating elements, limits, and fuse boxes for electric heat options.

Provides a method to verify refrigerant charge using subcooling and operating pressures.

Outlines essential pre-startup checks for electrical connections, voltage, and blower belt.

Details the procedure for initiating cooling mode, including compressor and fan operation.

Explains the process of placing the furnace in operation, including gas valve and burner procedures.

Covers gas piping, testing procedures, and manifold pressure checks for proper gas heating operation.

Details checks for refrigerant charge, subcooling, and electrical components during cooling operation.

Instructions for accessing, checking, and replacing air filters for optimal unit performance.

Information on lubrication requirements for unit components, noting most are pre-lubricated.

Guidance on inspecting and cleaning the supply air blower wheel for accumulated dirt.

Procedures for inspecting and cleaning the evaporator coil and checking the condensate system.

Recommendations for cleaning the condenser coil annually and inspecting it monthly.

Guidance on checking all wiring connections, voltage, and amp-draw for proper electrical function.

Information on roof mounting frames for unit installation, ensuring stability and levelness.

Details optional supply/return transitions used with roof mounting frames for unit installation.

Information on optional diffusers/returns for air distribution, referring to manufacturer instructions.

Describes outdoor air dampers for controlling fresh air intake and their filter maintenance.

Explains the function and modes of the optional economizer for free cooling applications.

Details gravity exhaust dampers used with economizers to manage exhaust air and prevent infiltration.

Information on the power exhaust fan assembly used for exhaust air pressure relief.

Details the optional cold weather kit for controlling gas burner compartment temperature in cold climates.

Presents the wiring diagram and sequence of operation for specific voltage configurations.

Displays the wiring diagram and sequence of operation for Y voltage units.

Shows the wiring diagram and sequence of operation for G, J, and M voltage units.

Step-by-step operational sequence for cooling, heating, and economizer functions.

Specific wiring diagram for gas heat units, detailing component connections and safety limits.

Outlines the operational sequence for gas heat, including first and second stage heating.

Describes how the thermostat interacts with the main control module and other sensors.

Explains the economizer's operation sequence, controlled by the main control module and sensors.

Details the wiring and sequence of operation for electric heating sections.

Step-by-step operational sequence for electric heating elements across different stages and voltages.