Page 29

9-Burner Controls A3

A3 controls gas heat section burner controls. Burner con

trols are factory set and are not adjustable. The control

makes three attempts at ignition and then locks out the sys

tem if ignition is not obtained after the third trial. Reset after

lockout requires only breaking and remaking thermostat

demand. The control shuts off gas flow immediately in the

event of a gas or power failure. Upon restoration of gas

and power, the control will restart the ignition sequence

and continue until flame is established or system locks

out. For a more detailed description see the Gas Heat

Components section.

10-Power Exhaust Relay K65 (PED units)

Power exhaust relay K65 is a N.O. DPDT relay with a

24VAC coil. K65 is used in all LGH units equipped with the

optional power exhaust dampers. K65 is energized by the

economizer control panel (A56), after the economizer

dampers reach 50% open (adjustable in ECTO). When K65

closes, the exhaust fans B10 and B11 are energized.

11-Blower Motor Overload Relay S42

Two hp high efficiency blower motors and M-volt unit blower

motors are equipped with an overload relay. High efficiency

blower motors and M-volt unit blower motors manufactured

before Dec. 19, 2010, are equipped with the relay. Ultra

high efficiency units equipped with a direct drive blower

have an internal overload.

The relay (S42) is connected in line with the blower motor to

monitor the current flow to the motor. When the relay sens

es an overload condition, a set of normally closed contacts

open to de-energize the blower. Units will be equipped with

a relay manufactured by Telemecanique figure 9 or

Siemens figure 10.

12-Unit Controller A55

The Unit Controller provides all unit control functions, unit

status information, unit diagnostics, programmable pa

rameters and USB verification and profile sharing. Use the

Unit Controller keypad and display to navigate through

menus. Software is also available to access the Unit Con

troller. Refer to the Unit Controller guide provided with the

unit. Thermostat wires are connected to J297 on the Unit

Controller.

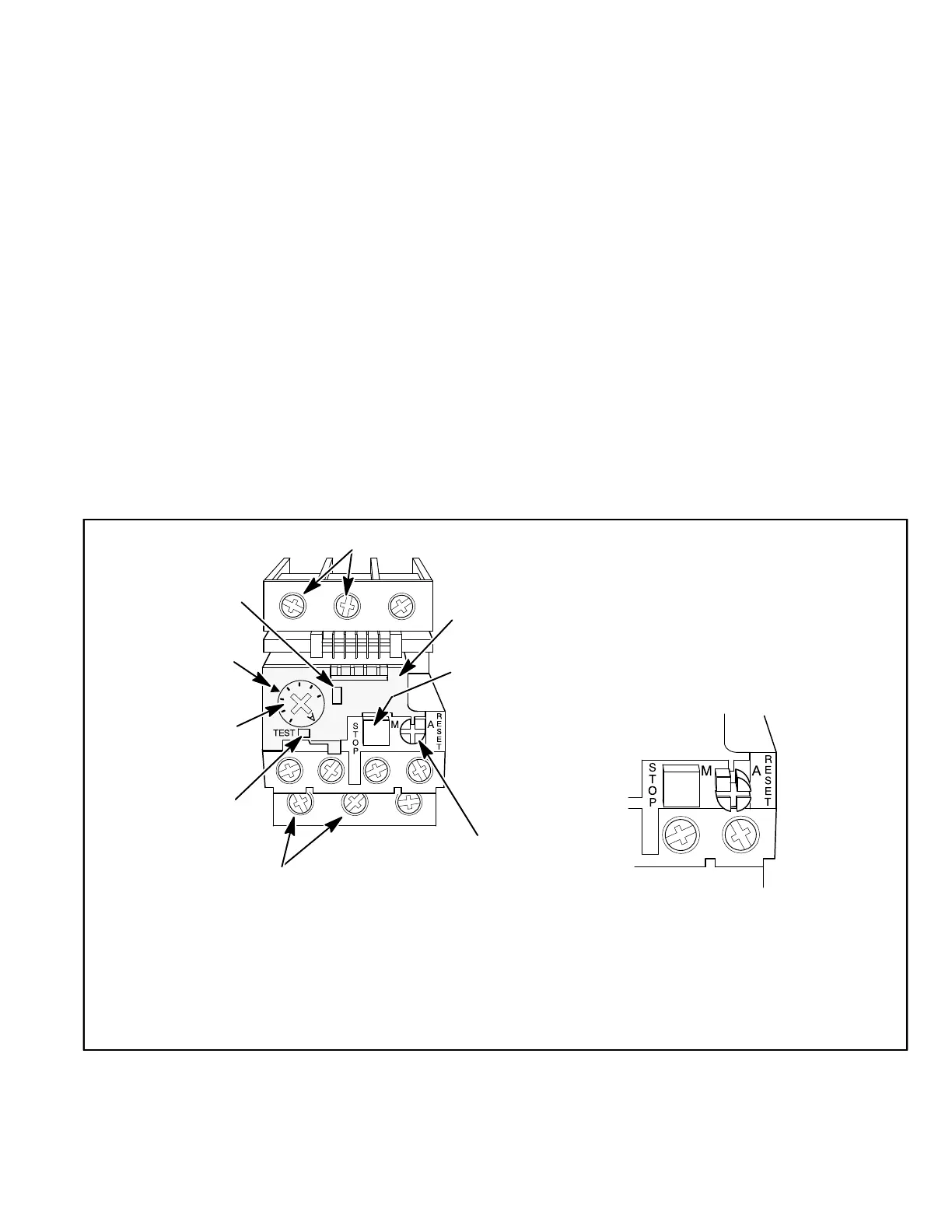

CLEAR

COVER

(SHOWN

CLOSED)

STOP

BUTTON

(RED)

RED TEST

BUTTON

(Push To Test)

AMP SETTING

CONTROL

(BLUE DIAL)

TRIP

INDICATION

WINDOW

LINE VOLTAGE IN

AMP SETTING

POINTER

BLUE RESET SCREW

(Shown in AUTO position as

shipped from the factory)

LOAD VOLTAGE OUT

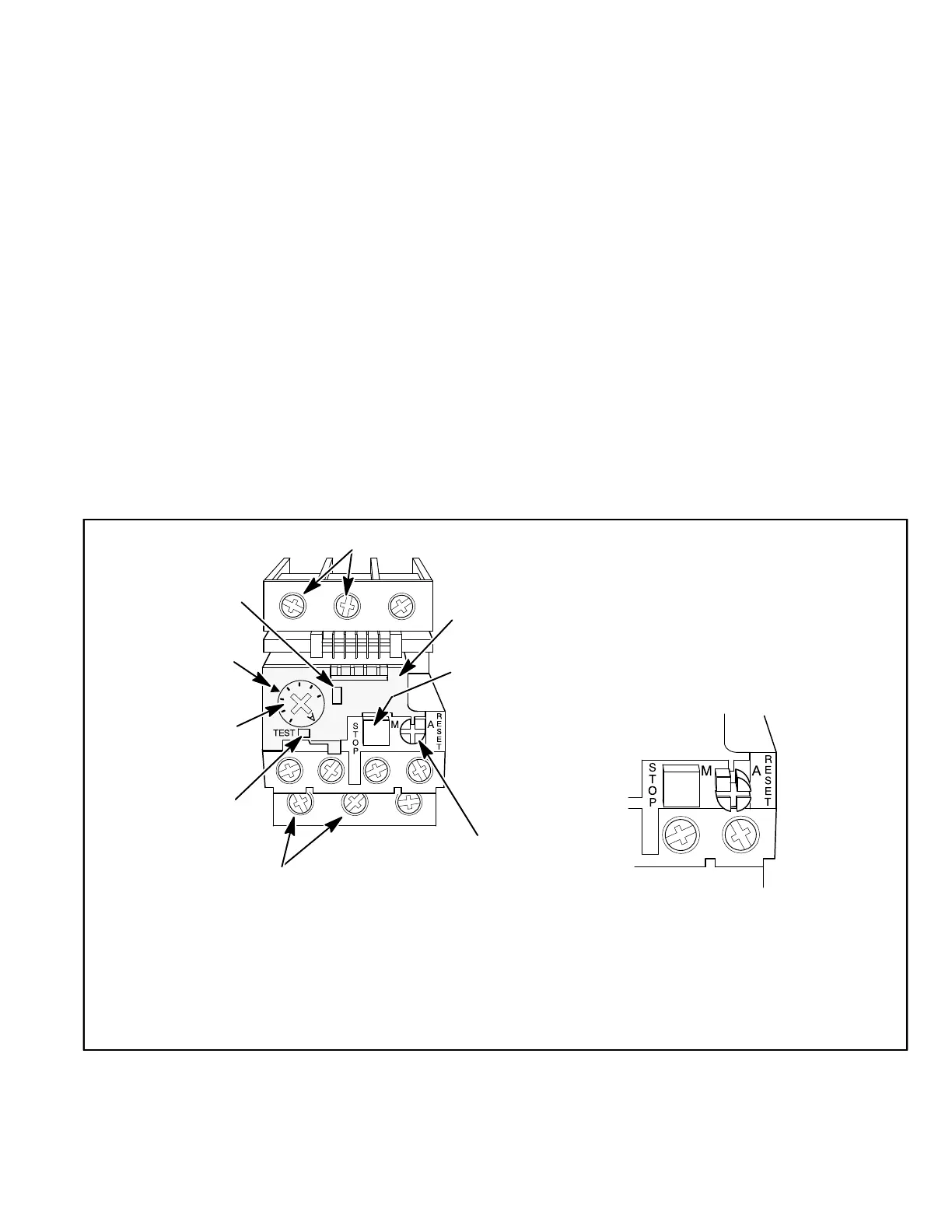

DETAIL SHOWING RESET BUTTON

ADJUSTED TO MANUAL POSITION

Lift clear cover and turn adjustment screw

counterclockwise. Reset screw will pop out

when pointer is in M (manual position). Close

cover to lock reset screw into position.

TELEMECANIQUE OVERLOAD RELAY

Lift clear cover to adjust relay amp setting according to value given on the blower motor nameplate.

Proper relay amp setting equals motor nameplate FLA X service factor of 1.15 X .95.

Cover must also be lifted to adjust control mode from automatic reset to manual reset (see detail

above) and to test the control.

Control must be in the manual reset mode to perform a test. Use a pointed object to press the small

red test button. A yellow marker should appear in the trip indication window to the right of the amp

setting control. Press the blue reset screw to reset the relay.

The red STOP button opens the normally closed contacts which power the blower motor. This button

stops blower motor operation as long as it is pressed in.

FIGURE 9

Loading...

Loading...