Page 40

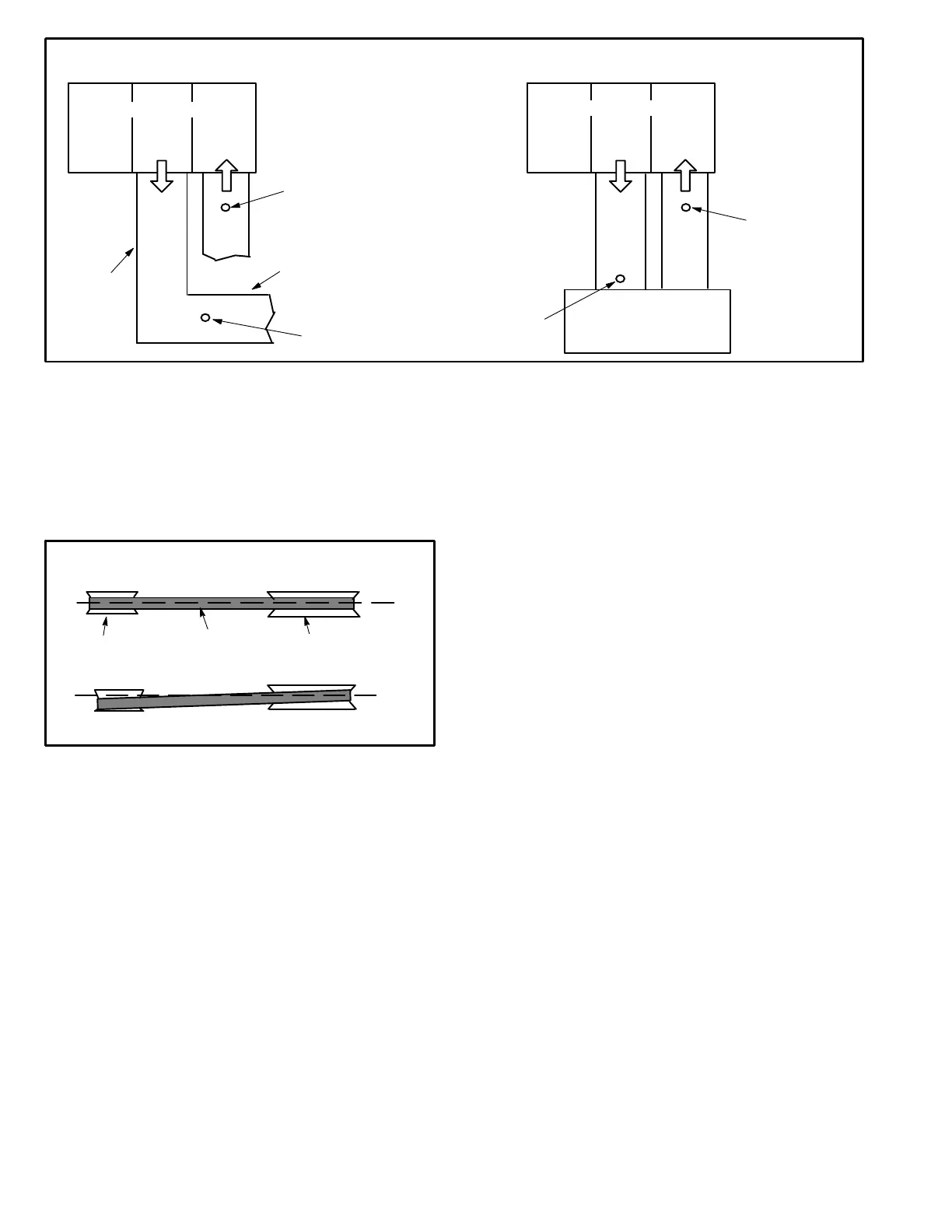

FIGURE 19

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

RE

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

RE

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are main

tained. Tension new belts after a 24-48 hour period of op

eration. This will allow belt to stretch and seat in the pul

ley grooves. Make sure blower and motor pulleys are

aligned as shown in figure 20.

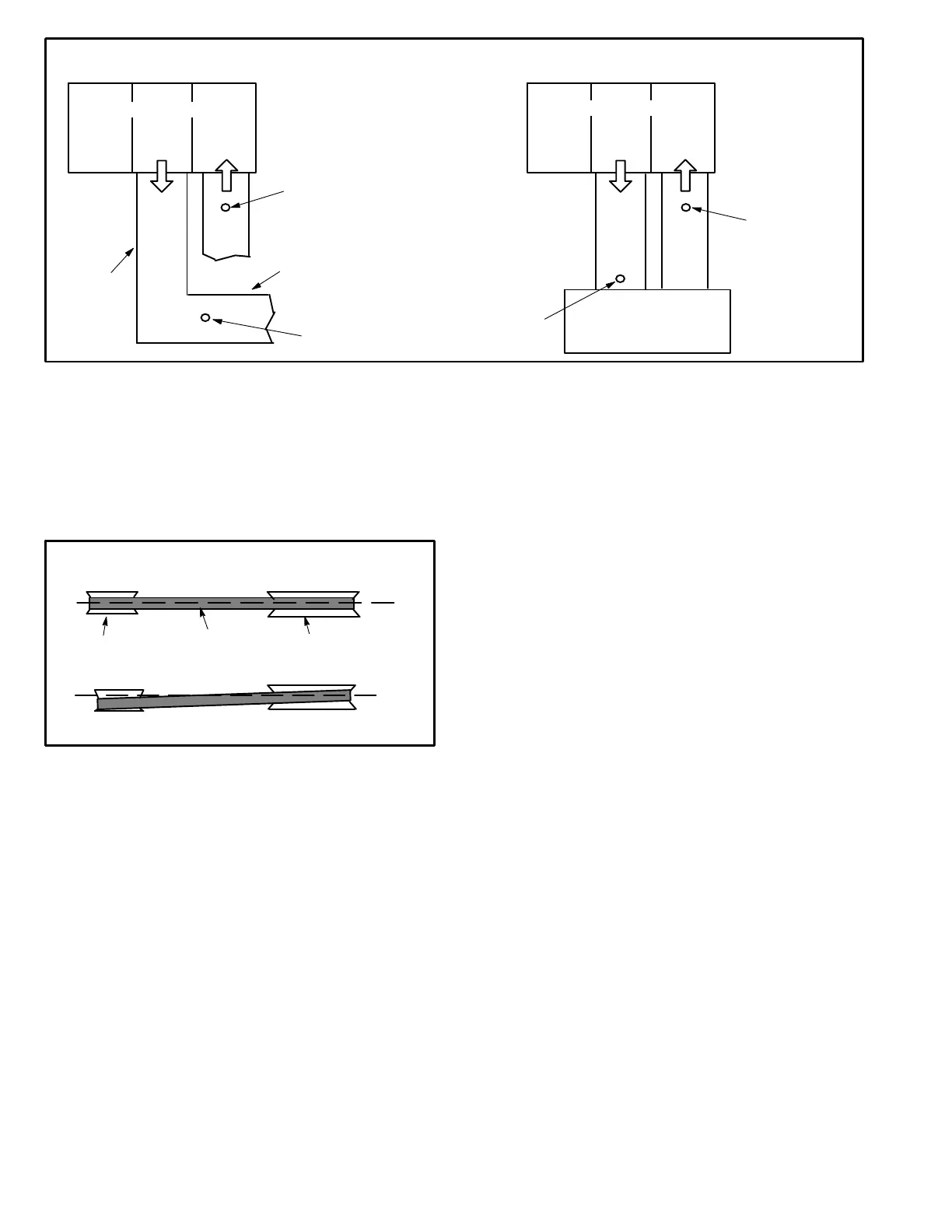

FIGURE 20

PULLEY ALIGNMENT

BELT

BLOWER PULLEY

MOTOR PULLEY

NOT ALIGNED

ALIGNED

1- Loosen four bolts securing motor base to mounting

frame. See figure 16 or 17.

2- To increase belt tension -

Turn both adjusting bolts to the right, or clockwise, to

move the motor outward and tighten the belt. This in

creases the distance between the blower motor and

the blower housing.

To loosen belt tension -

Turn the adjusting bolt to the left, or counterclockwise

to loosen belt tension.

IMPORTANT - Align edges of blower motor base and

mounting frame base parallel before tightening four bolts

on the side of base. Motor shaft and blower shaft must be

parallel.

3- Tighten bolts on side of base.

Loading...

Loading...