15

If the outdoor unit is installed on eld-provided wall

mounting brackets, use lag bolts or equivalent to secure

the outdoor unit to the bracket. Minimum rear clearance

can be reduced to 6 inches (152 mm) when mounted

on brackets and with no obstructions on the other three

sides. Allow for condensate disposal when placing units

above one another.

Air Outlet

Air Inlet

6 in

152 mm

Figure 29.

Refrigerant Piping Connections

Line sets consists of two copper pipes connecting the

outdoor unit to the indoor unit. “Table 3. Refrigerant Piping

and Indoor Unit Connection Sizes” lists the connection

sizes. The connections are made using the provided brass

are nuts at the end of the refrigerant piping connections.

1. Choose the correct pipe sizes for your application

using “Table 3. Refrigerant Piping and Indoor Unit

Connection Sizes”.

2. Conrm that you are using the correct diameter piping.

3. Determine the necessary piping length required for the

application.

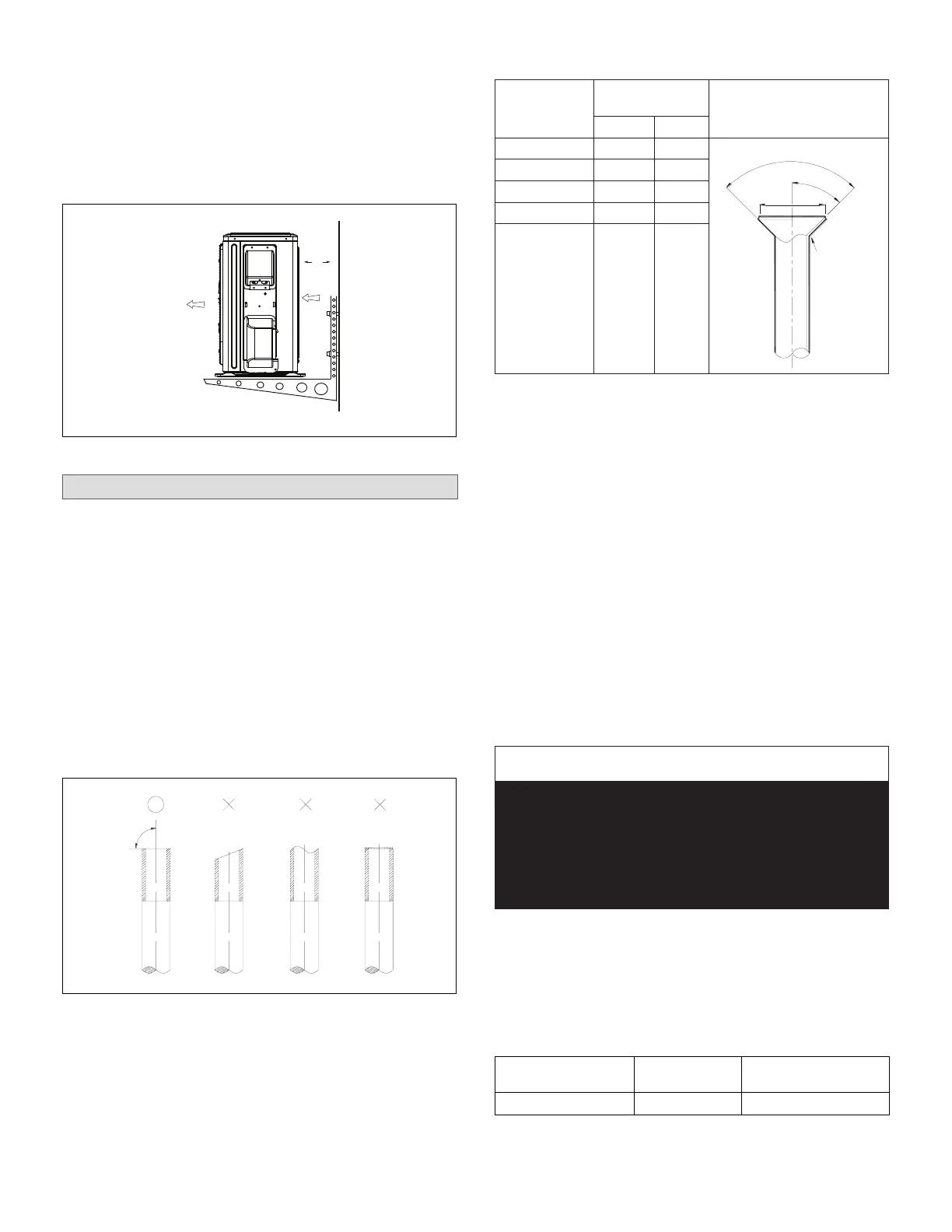

4. Cut the selected pipes with a pipe cutter. Make the

cuts at and smooth as illustrated in “Figure 30.

Cutting Pipe”.

Figure 30. Cutting Pipe

5. Insulate the copper piping.

6. Insert a are nut onto each pipe before aring.

7. Use “Table 2. Flaring Piping” to properly are the pipe.

Table 2. Flaring Piping

Pipe Diameter

Flare Dimension

Flare Shape

Min Max

1/4” (6.35) 8.3 8.7

R0.4~0.8

A

45

°

90°

4

-

+

3/8” (9.62) 12.0 12.4

1/2” (9.52” 15.4 15.8

5/8” (15.9) 18.6 19.1

3/4” (22.9) 22.9 23.3

8. After aring the pipe, temporarily sealed pipe ends with

adhesive tape to avoid contaminants from entering the

pipes.

9. The seal on the unit refrigerant piping connections

should remain in place until the last possible moment.

This will prevent dust or water from getting into the

refrigerant piping before it is connected.

10. CAREFULLY adjust refrigerant piping connections to

suit the application.

11. Slowly loosen one of the are nuts to release the

factory nitrogen charge from the indoor units only.

12. Remove the are nuts from the connections on the

unit and discard the seal from each of the piping

connections.

13. Slide the are nuts onto the ends of the eld-provided

refrigerant piping before using a suitable aring tool to

are the end of the copper pipe.

14. Apply recommended HFC-410A refrigerant lubricant

to the outside of the ared refrigerant lines.

IMPORTANT

The compressor in this unit contains PVE

oil (Polyvinylether). PVE oil is formulated for

hydrouorocarbon (HFC) refrigerants, such as HFC-

410A, which this system contains. While it may have

some miscibility properties with mineral-based oil and

POE oil (Polyolester), it is not recommended to mix PVE

oil with any other type of refrigerant oil.

15. Align the threaded connections with the

ared refrigerant lines. Tighten the are nuts

lightly at rst to obtain a smooth match as

illustrated in “Figure 31. Making Connections

(Male to Female Connection)”.

Table 3. Refrigerant Piping and Indoor Unit

Liquid Line

in.

Gas Line

in.

18000 1/4 1/2

Loading...

Loading...