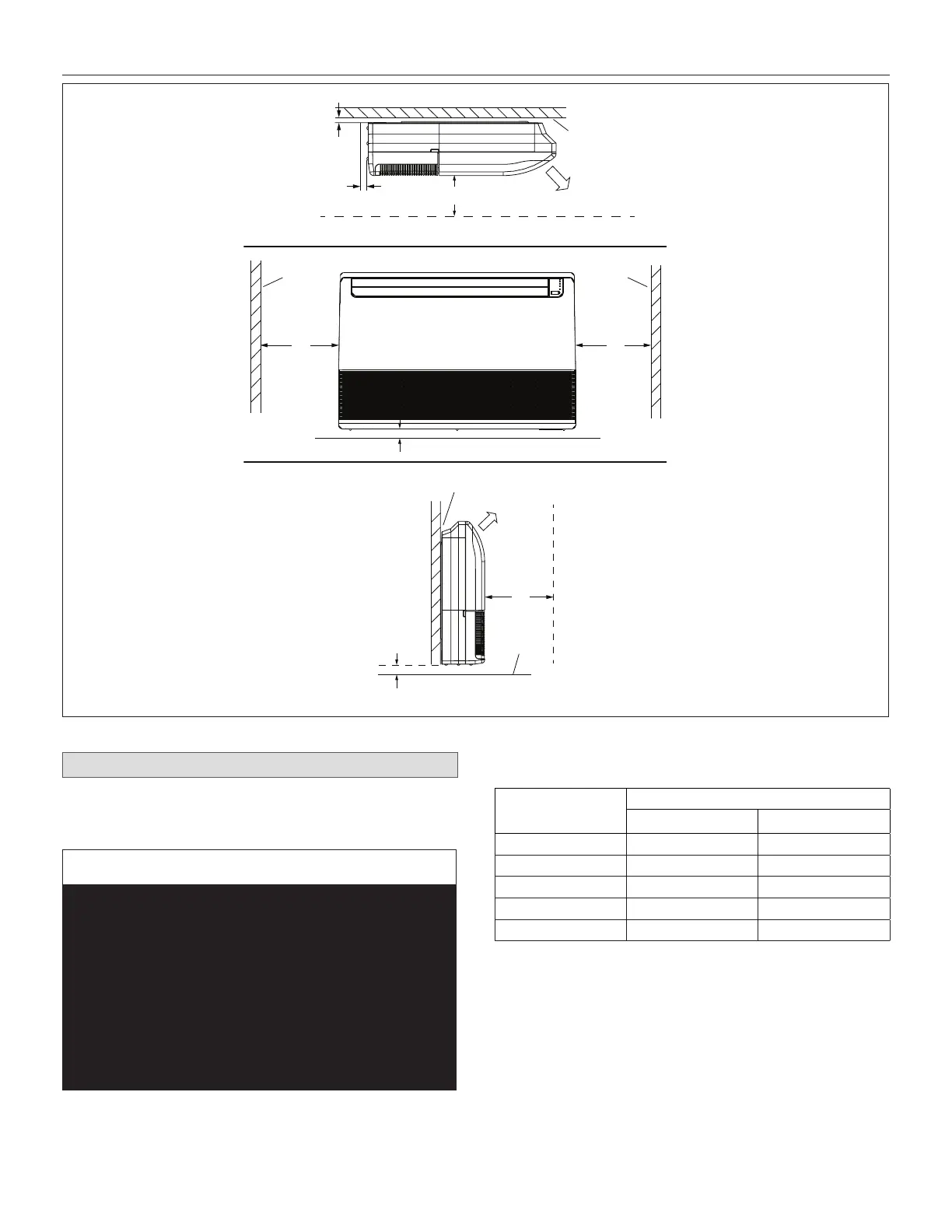

9

24

(610)

24

(610)

FRONT VIEW

SIDE VIEW

SIDE VIEW

SUPPLY

AIR

SUPPLY

AIR

59 (1499)

(Service Clearance

Front of Unit)

DROP CEILING

3/4

(19)

WALL WALL

CEILING AND FLOOR APPLICATIONS

FLOOR APPLICATIONS

Unit Flush with Wall

59 (1499)

(Service Clearance

Floor

1 (25) Minimum

1 (25) Minimum

1 (25)

Minimum

Figure 10.

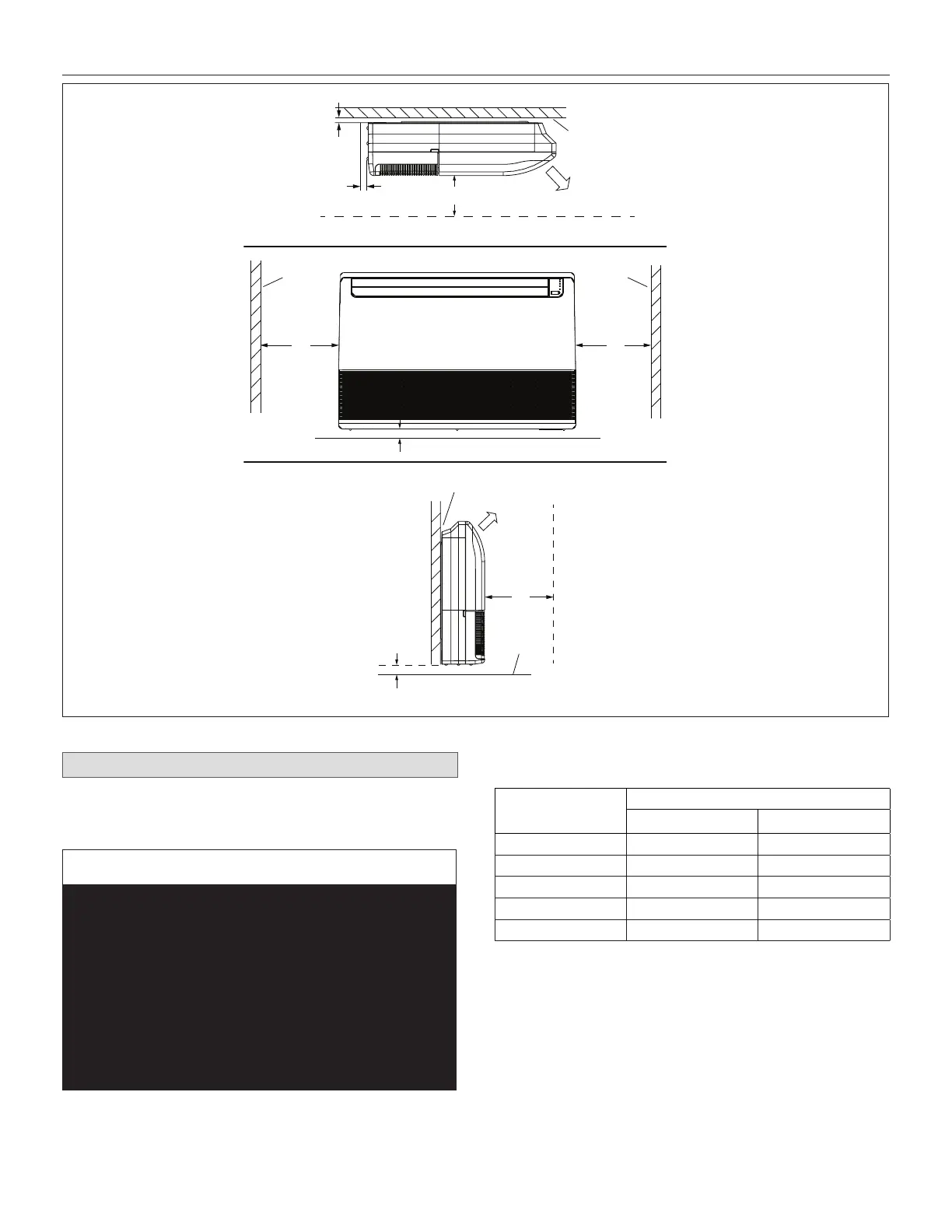

Torque Requirements for Caps and Fasteners

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. “Table 1. Torque

Requirements” provides torque values for fasteners.

IMPORTANT

Only use Allen wrenches of sufcient hardness (50Rc -

Rockwell scale minimum). Fully insert the wrench into

the valve stem recess.

Service valve stems are factory-torqued from 9 ft.-lbs.

(12 N) for small valves, to 25 ft.-lbs. (34 N) for large

valves) to prevent refrigerant loss during shipping and

handling. Using an Allen wrench rated at less than 50Rc

risks rounding or breaking off the wrench, or stripping

the valve stem recess.

See the Lennox Service and Application Notes C-08-1

for further details and information.

Table 1. Torque Requirements

Parts

U.S. Newton-Meter- N

Service valve cap 8 ft.-lb. 11

Sheet metal screws 16 in.-lb. 2

Machine screws #10 27 in.-lb. 3

Compressor bolts 7 ft.-lb. 10

Gauge port seal cap 8 ft.-lb. 11

Loading...

Loading...