26

P5

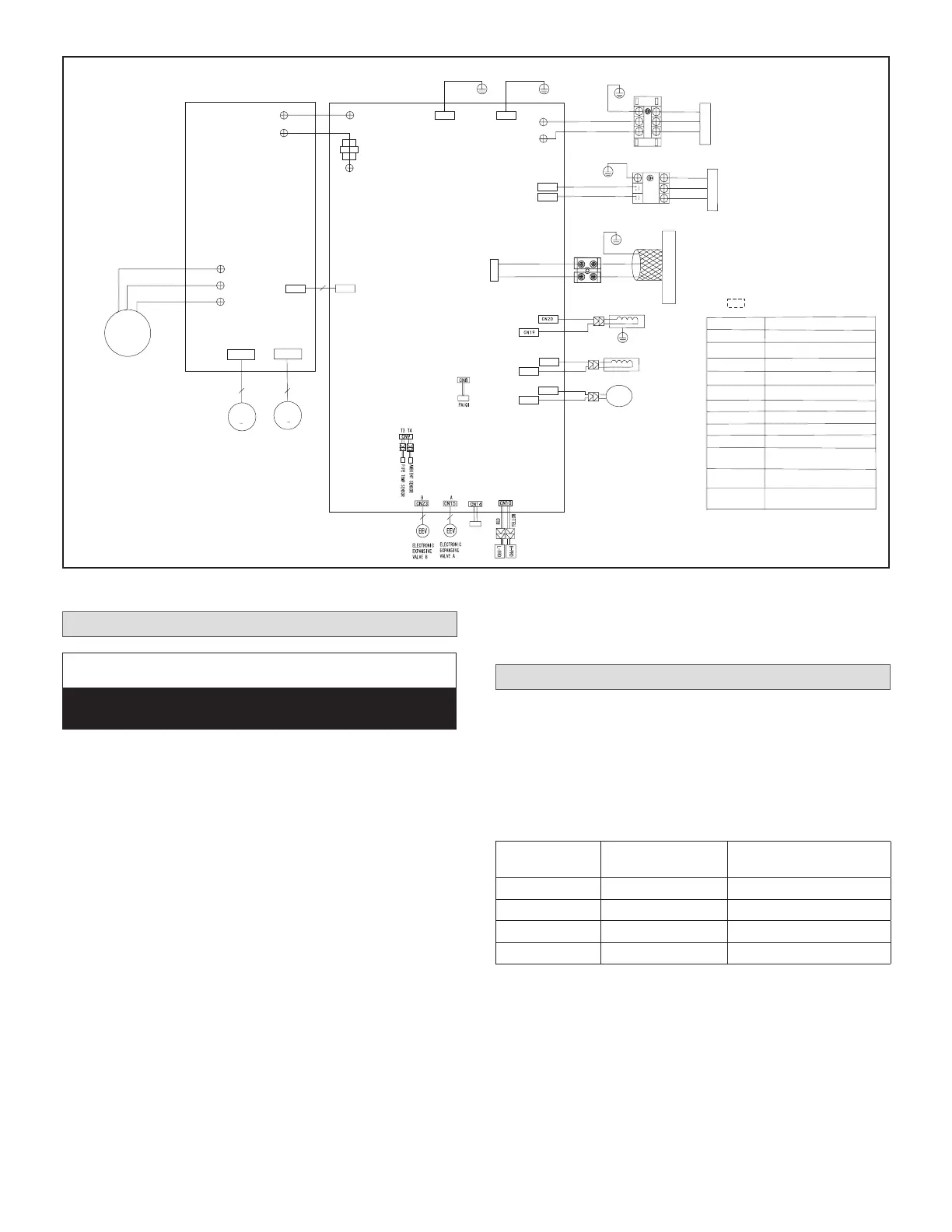

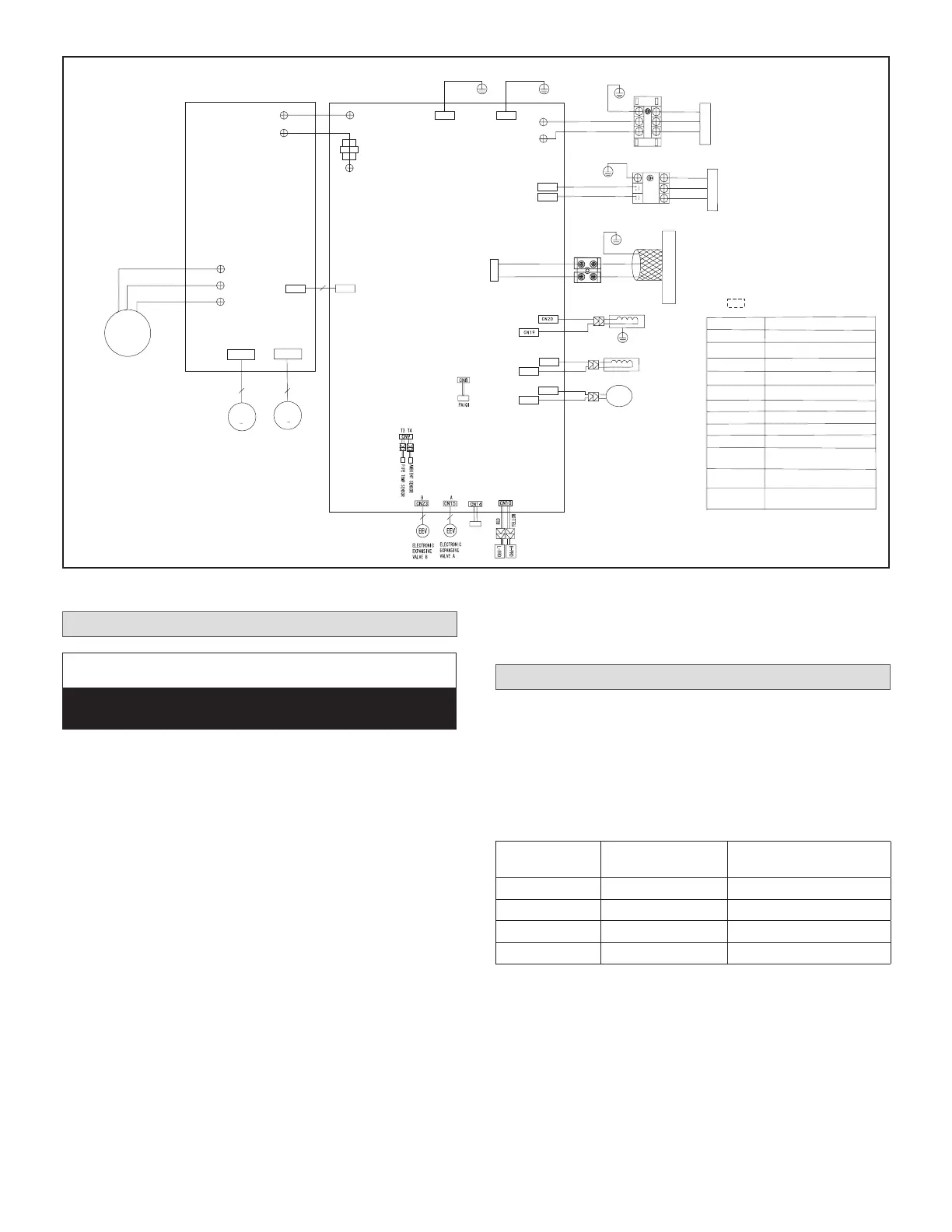

CN24

CN25

CN17

CN8

CN18

HEAT_Y

SV

4-WAY

BLUE

CN4

CN2

CN3

CN1

COMP

U

V

W

CN6

CN9

10

CN2

U

V

W

BLUE

BLACK

RED

RED

BLACK

CT1

DCFAN2

DCFAN1

6

3

P6

CN3

Outdoor main Controller

BLUE

Y/G

Y/G

COMP TOP

OLP TEMP

SENSOR

Notes:

CN5

CODE

PART NAME

COMP

CAP1,CAP2

COMPRESSOR

FAN MOTOR CAPACITOR

EEV

DCFAN1,DCFAN2

OUTDOOR DC FAN

HEAT_D,HEAT_Y

H-PRO

CRANKCASE HEATING

HIGH PRESSURE SWITCH

L-PRO

4-WAY

PAIQI

T3

T4

LOW PRESSURE SWITCH

4-WAY VA LVE

EXHAUST TEMPERATURE

SENSOR

CONDENSER TEMPERATURE

SENSOR

OUTDOOR AMBIENT

TEMPERATURE SENSOR

AC CURRENT DETECTOR

ELECTRIC EXPANSIVE VALVE

CT1

IPM&PFC BOARD

This symbol indicates the element is optional,

the actual shape shall be prevail.

HEAT_D

BLACK

RED

TO INDOOR UNIT

(1)L1

Y/G

XT2

(2)L2

P7

P8

BROWN

BLUE

TO INDOOR COMM. BUS

YELLOW

GRAY

S1

S2

NOTE:Please use 2-core

shielded wire.

XT3

CN22

P

Q

Y/G

L2

L1

XT1

Y/G

POWER SUPPLY

RED

BLACK

6

3

RED

BLACK

WHITE

The electric heating

belt of chassis

The electric heating

belt of compressor

RED

BLACK

RED

Figure 44. 208/230V MLB036S4S-*P and MLB048S4S-*P Outdoor Unit Wiring Diagram

Unit Start-Up

IMPORTANT

Units should be energized 24 hours before unit start-up

to prevent compressor damage as a result of slugging.

1. Inspect all factory- and eld-installed wiring for loose

connections.

2. Verify that the manifold gauge set is connected.

3. Add additional refrigerant charge if required before

opening valves and while system is still under a

vacuum.

4. Open the liquid and gas line service valves to release

the refrigerant charge contained in outdoor unit into

the system.

5. Replace the stem caps and tighten to the value listed

in “Table 4. Flare Nut Torque Recommendations” on

page 16.

6. Check voltage supply at the outdoor unit terminal strip.

The voltage must be within the range listed on the

unit’s nameplate. If not, do not start the equipment

until you have consulted with the power company and

the voltage condition has been corrected.

7. Refer to the included user guide to operate the system

using the provided remote control.

8. Visually check for binding of both indoor and outdoor

fans.

Adding Refrigerant for Longer Line Set

The outdoor unit is factory-charged with refrigerant.

Calculate the additional refrigerant required according to

the diameter and the length of the liquid pipe between the

outdoor unit and indoor unit connections.

Be sure to add the proper amount of additional refrigerant.

Failure to do so may result in reduced performance.

Table 8. Additional Refrigerant Charge

Pipe Length

Amount of Refrigerant

to add

18 >25 (7.5) 0.161 oz/ft (15g/m)

24 >25 (7.5) 0.322 oz/ft (30g/m)

36 >25 (7.5) 0.322 oz/ft (30g/m)

48 >25 (7.5) 0.322 oz/ft (30g/m)

Loading...

Loading...