ML193UH / Page 2

WARRANTY

Duralok Plus

™

Aluminized Steel Heat Exchanger -

Limited twenty warranty in residential applications, ten

years in non-residential applications.

All other covered components - Limited ve year

warranty in residential applications, one year in non-

residential applications.

Refer to Lennox Equipment Limited Warranty certicate

included with equipment for details.

APPROVALS

Units are Certied by AHRI.

Units tested and rated according to US DOE test

procedures and FTC labeling regulations.

ISO 9001 Registered Manufacturing Quality System.

Blower data from unit tests conducted in Lennox

Laboratory air test chamber.

APPLICATIONS

Input capacities of 44,000, 66,000, 88,000, 110,000 and

132,000 Btuh.

Energy efciency (AFUE) of 93%.

Compact cabinet for upow, horizontal-left or horizontal-

right applications without any modications.

Utility room, alcove, closet, crawl space, basement or

attic installation.

Lennox add-on indoor coils, high-efciency air cleaners

and humidiers can easily be added to furnace.

Shipped factory assembled with all controls installed

and wired.

Ready for installation in upow, horizontal right-hand or

horizontal left-hand position without any modications.

Removable bottom seal panel shipped in place for side

return air is easily removed for bottom/end return air

applications.

A

Each unit factory test operated to ensure proper

operation.

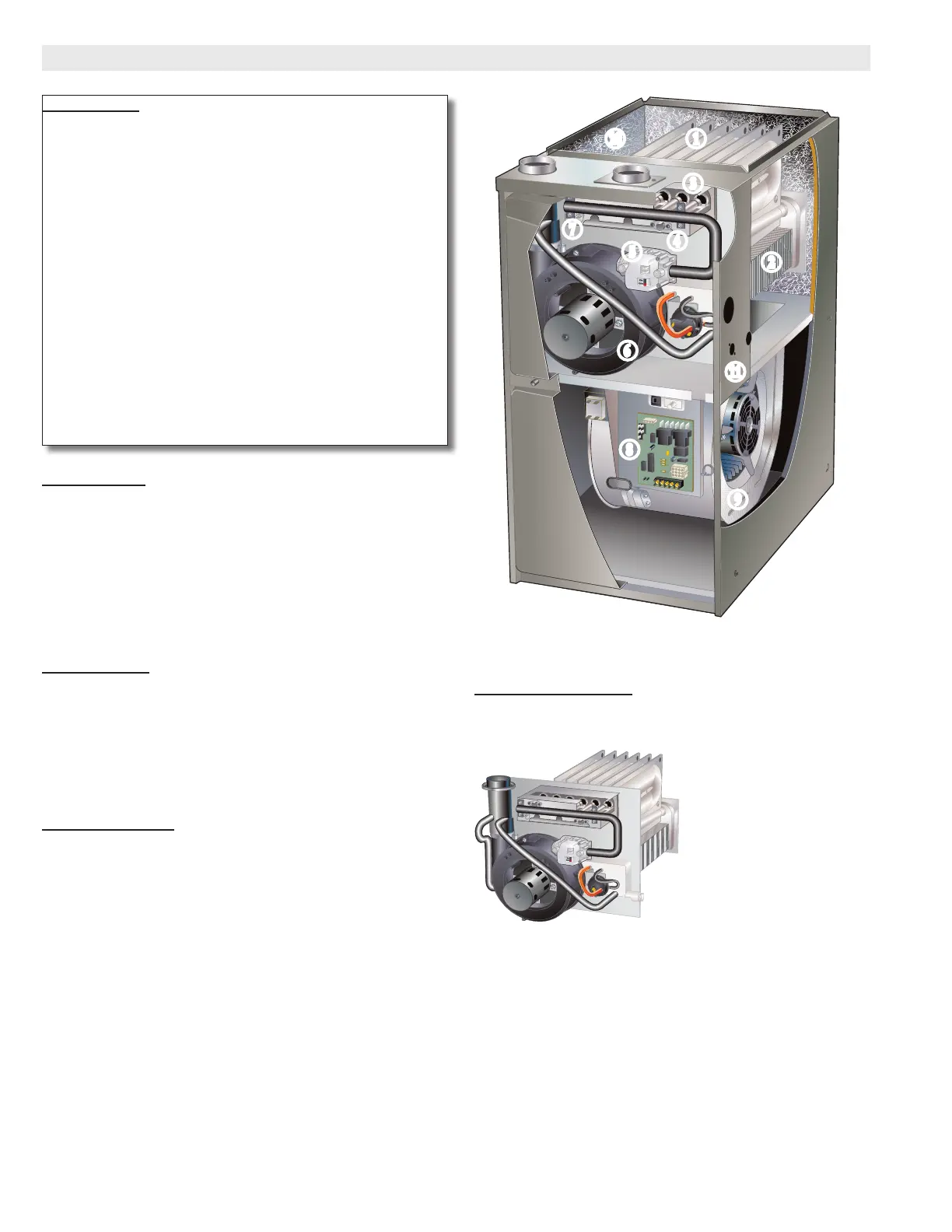

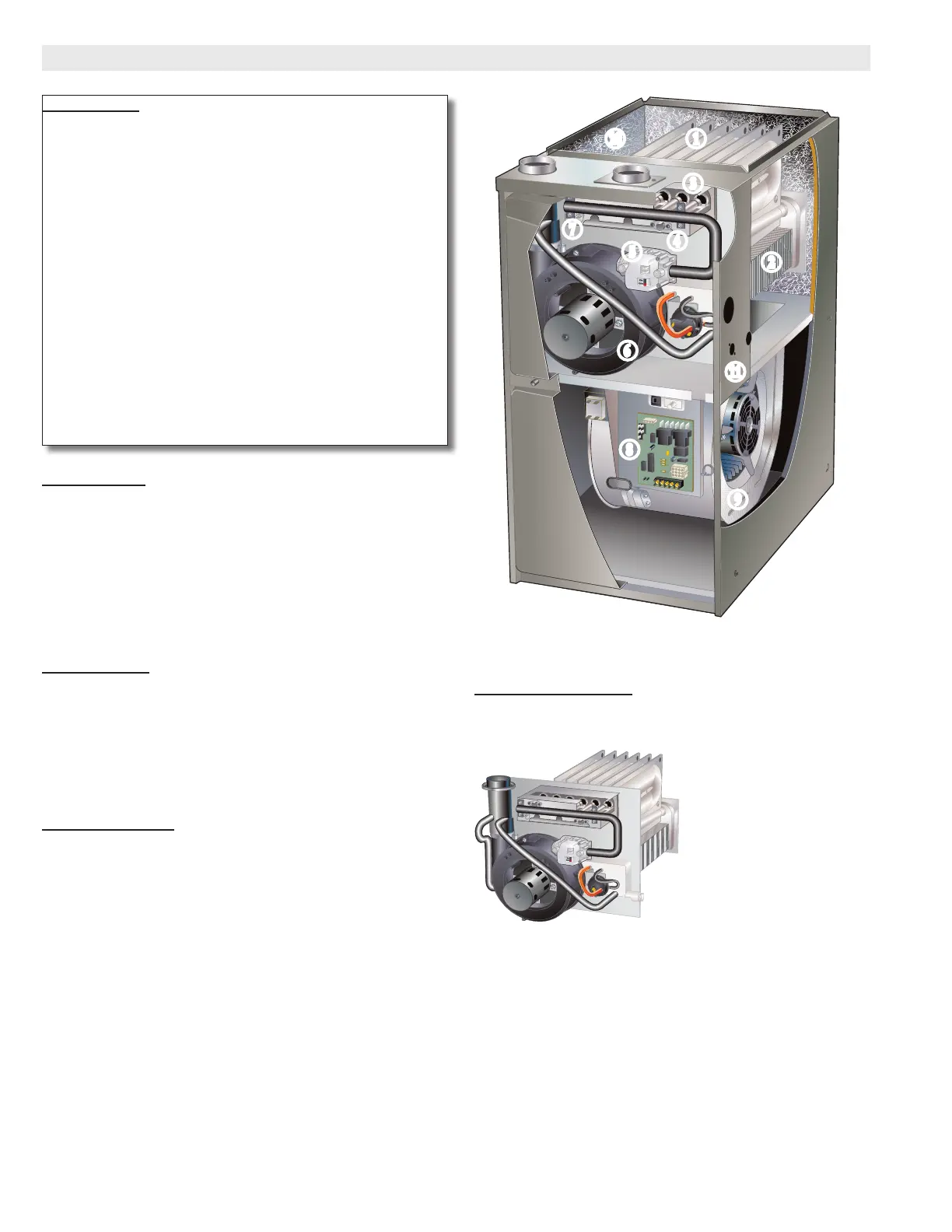

HEATING SYSTEM

Lennox Duralok Plus

™

Heat Exchanger Assembly

Lennox developed heat exchanger assembly consists

of primary heat exchanger

and secondary condenser

coil assembly.

Main multi-pass crimped

seam design clamshell

type heat exchanger.

Constructed of heavy-

gauge, aluminized steel.

Designed for normal

expansion and contraction

with maximum efciency and minimum resistance to air

ow.

Secondary heat exchanger condenser coil constructed

of aluminum ns tted to stainless steel tubes.

Coil is factory tested for leaks.

Condensate drain header box assembly located on front

of coil.

Compact size of complete heat exchanger assembly

permits low overall design of furnace cabinet.

Heat exchanger assembly has been laboratory life cycle

tested in excess of industry standards..

B

C

FEATURES

Contents

Blower Data . . . . . . . . . . . . . . . . . . . . . . 17

Dimensions - Furnace/Coil Combined Dimensions . . 13

Dimensions - Horizontal Position . . . . . . . . . . . 11

Dimensions - Upow Position. . . . . . . . . . . . . 10

Features. . . . . . . . . . . . . . . . . . . . . . . . 2

Gas Heat Accessories . . . . . . . . . . . . . . . . 8

Installation Clearances . . . . . . . . . . . . . . . . 7

Model Number Identication . . . . . . . . . . . . . 1

Optional Accessories . . . . . . . . . . . . . . . . . 8

Optional Accessory Dimensions . . . . . . . . . . . 12

Specications . . . . . . . . . . . . . . . . . . . . . 6

Termination Kits Usage . . . . . . . . . . . . . . . . 9

Vent Lengths . . . . . . . . . . . . . . . . . . . . . 9

B

C

D

E

F

G

H

I

J

K

L

Loading...

Loading...