Maintenance

Maintenance operations

Lubricate roller bearings

7

63

Lenze ¯ MA 12.0014 ¯ 5.1

7.3.5 Lubricate roller bearings

The roller bearings on motors and gearboxes from Lenze are filled with the greases

listed below:

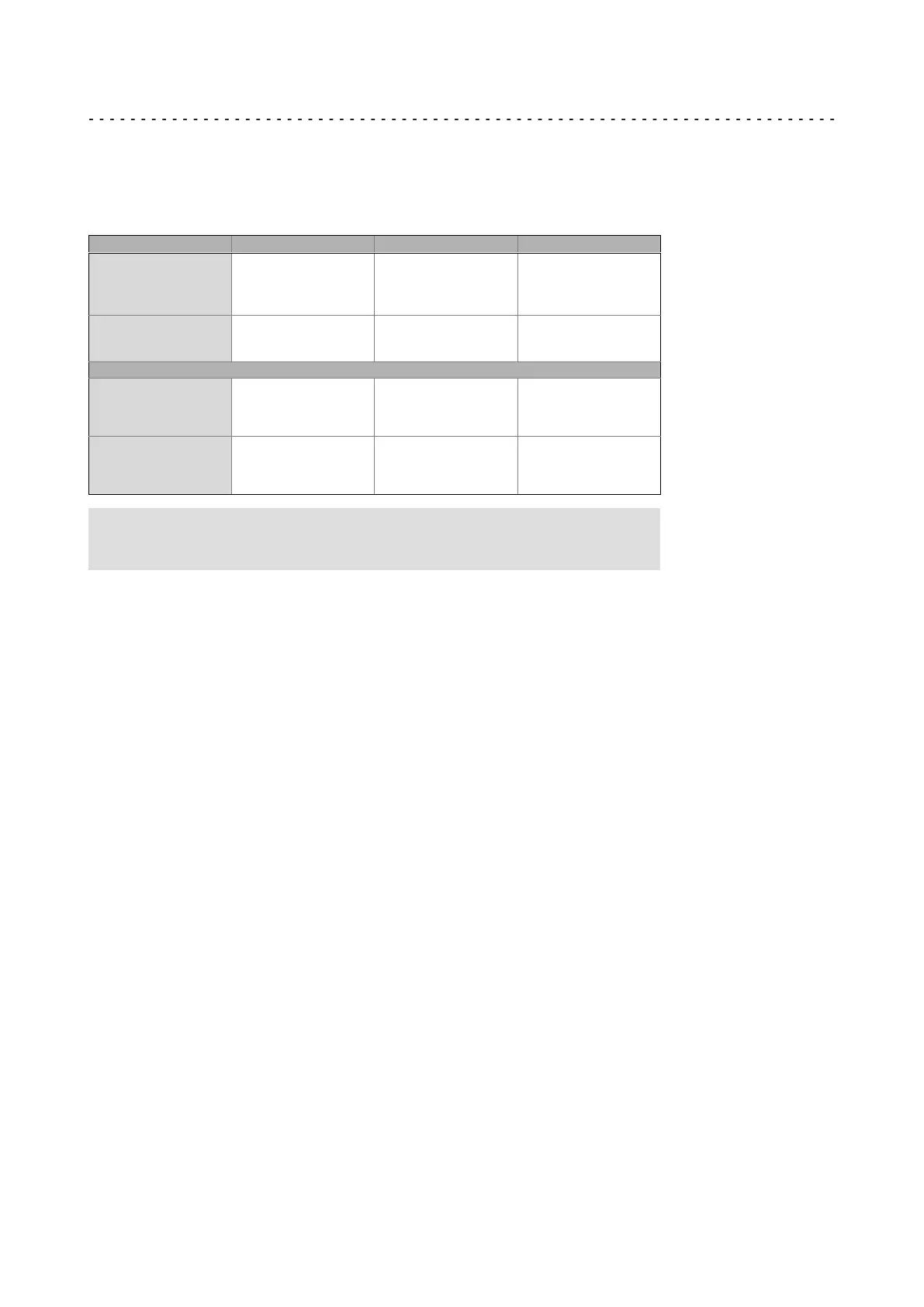

Ambient temperature Manufacturer Type

Gearbox roller bearing

−30 °C ... +50 °C

−30 °C ... +80 °C

−40 °C ... +60 °C

Fuchs

Klüber

Klüber

Renolit H 443

Petamo 133 N

Microlube GLY 92

Motor roller bearing

−30 °C ... +70 °C

−40 °C ... +80 °C

Lubcon

Klüber

Thermoplex 2TML

Asonic GHY 72

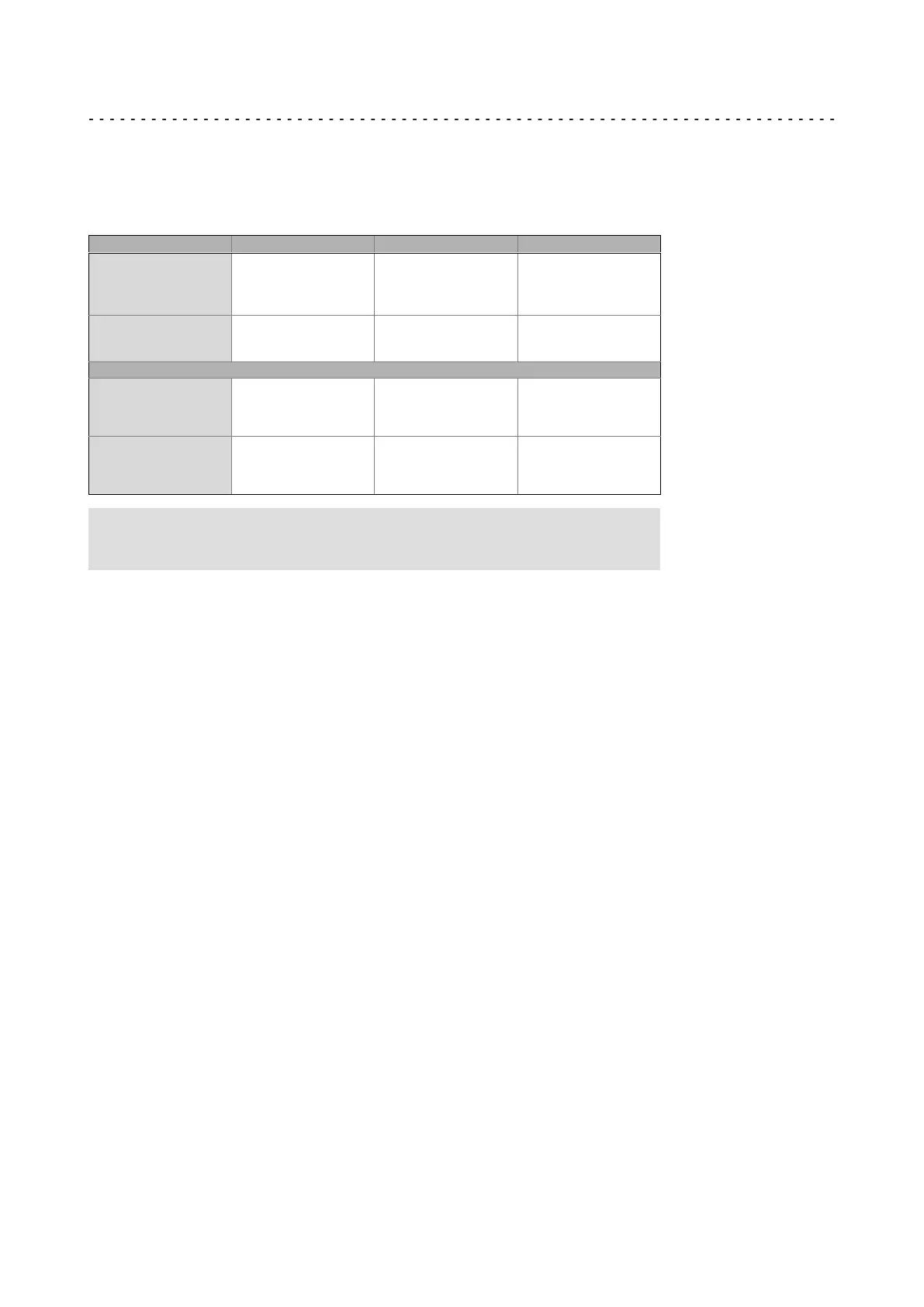

Special grease for gearbox roller bearings

Low−temperature oils,

observe critical starting

performance at low

temperatures

−40 °C ... +80 °C Klüber Asonic GHY 72

Biopetroleum (lubricant

for forestry, agriculture

and water supply and

distribution)

−40 °C ... +50 °C Fuchs Plantogel 0120S

) Note!

Clean roller bearings before applying new grease!

The following lubricant quantities are required:

¯ For fast−running bearings (drive−end gearbox): fill approx. one−third of the hollow

space between rolling bodies with grease.

¯ For slow−running bearings (within gearbox and driven side of gearbox): fill

approx. two−thirds of the hollow space between roller bearings with grease.

Loading...

Loading...