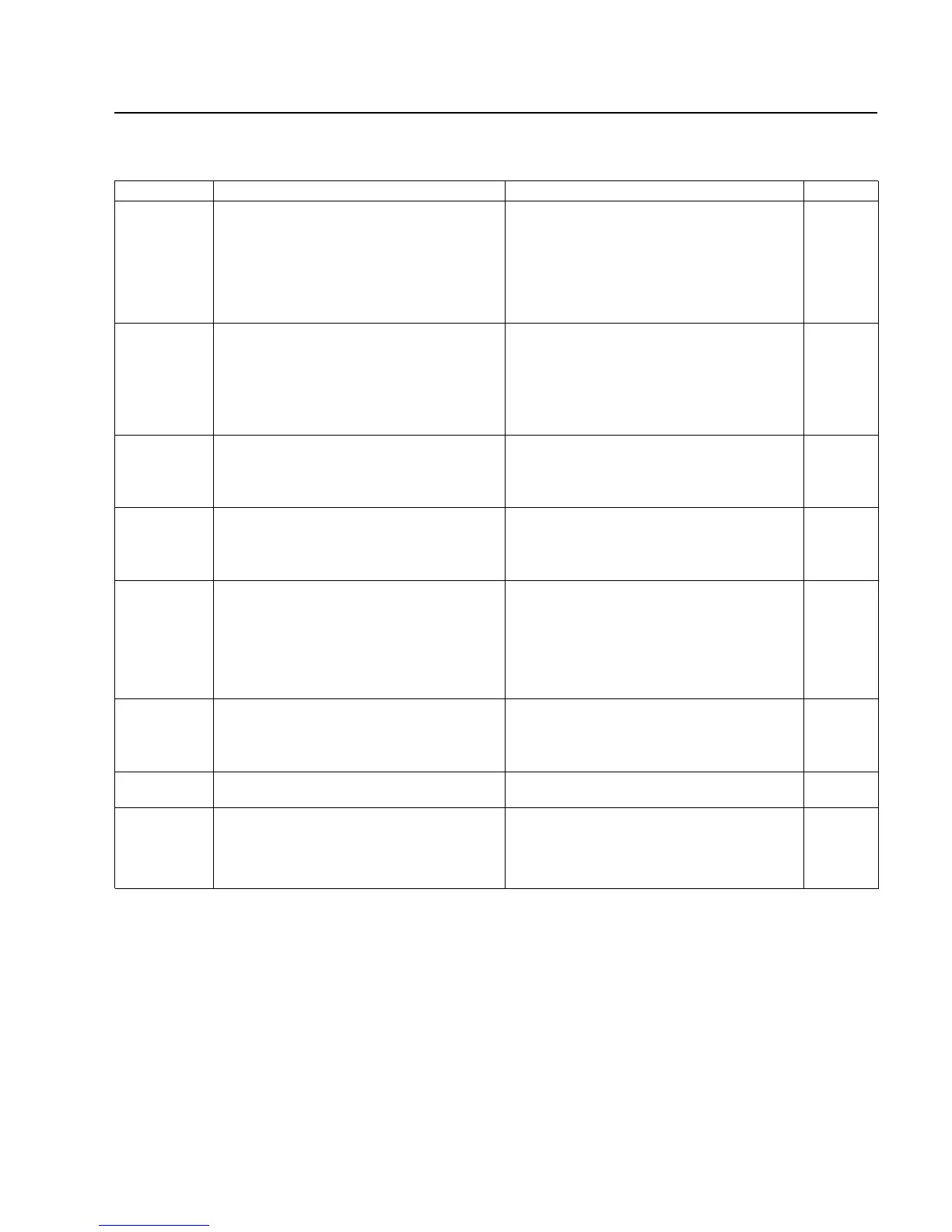

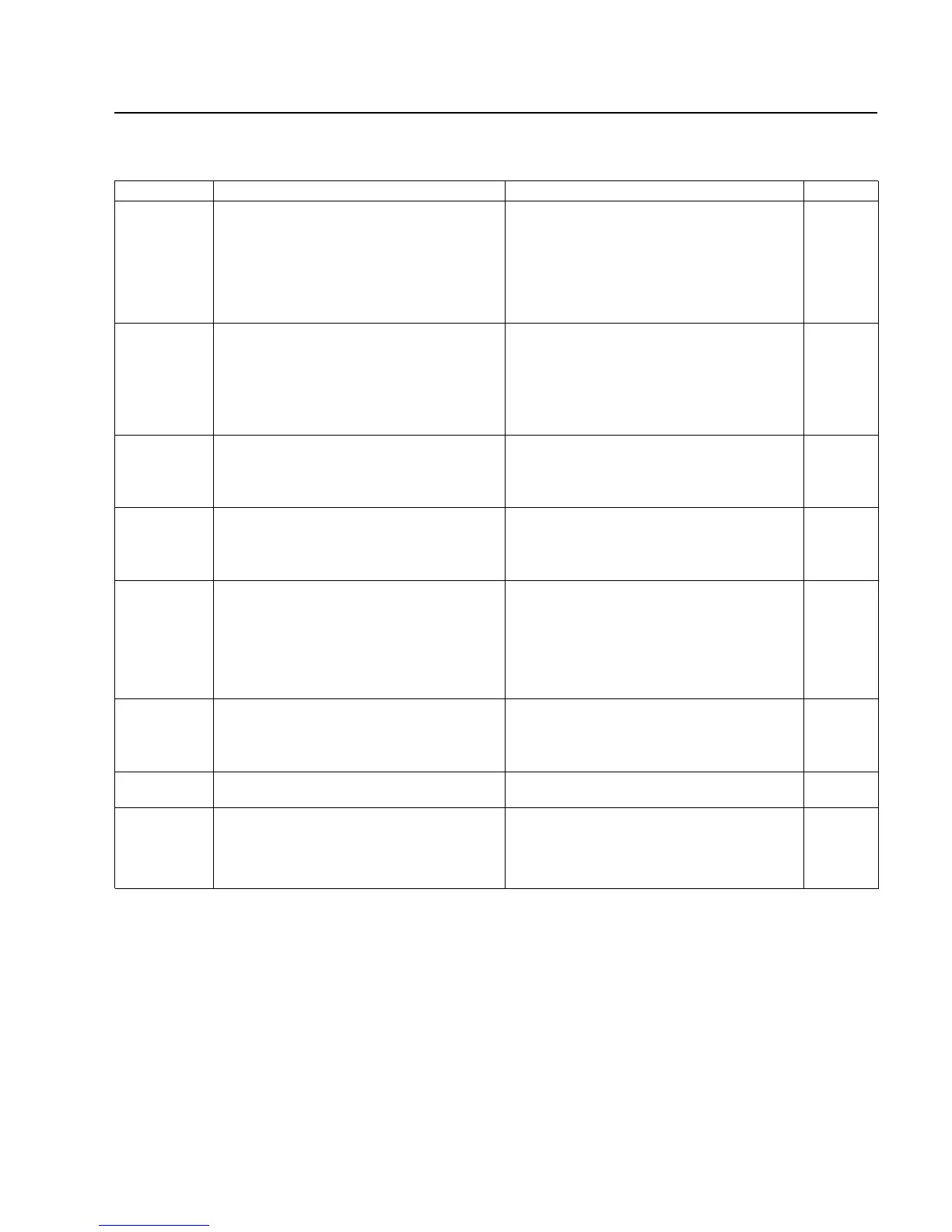

4 Troubleshooting

Fault Possible cause Remedy Repair*

Pump does not

start.

Pump does not

reach ultimate

pressure.

Wiring is malfunctioning.

Motor protection switch incorrectly set

(3-phase motors only).

Operating voltage does not match motor.

Motor is malfunctioning.

Oil temperature is below 12 °C.

Oil is too viscous.

Exhaust filter or exhaust line is clogged.

Check and repair wiring.

Set motor protection switch properly.

Replace the motor.

Replace the motor.

Heat the pump and pump oil or use different oil.

Change the oil.

Replace the filter or clean the exhaust line.

Repair the pump.

-

2.3

3.5

3.5

2.5.3/3.2

3.2

-

Service

Measuring technique or gauge is unsuitable.

External leak

1)

.

Anti-suckback valve is malfunctioning.

Exhaust valve is malfunctioning.

Oil is unsuitable.

Intake line is dirty.

Pump is too small.

Use correct measuring technique and gauge.

Measure the pressure directly at pump’s intake port.

Repair the pump.

Repair the valve.

Repair the valve.

Change the oil (degas it, if necessary).

Clean vacuum lines.

Check the process data; replace the pump, if necessary.

-

Service

Service

Service

3.2

-

-

Pumping speed is

too low.

Dirt trap in the intake port is clogged.

Exhaust filter is clogged.

Connecting lines are too narrow or too long.

Clean the dirt trap;

Precaution: install a dust filter in intake line.

Exchange the filter element.

Use adequately wide and short connecting lines.

3.3

-

2.2

Pump gets hotter

than usually

observed.

Cooling air supply is obstructed.

Ambient temperature is too high.

Process gas is too hot.

Oil level is too low.

Oil is unsuitable.

Oil cycle is obstructed.

Exhaust filter or exhaust line is obstructed.

Exhaust valve is malfunctioning.

Pump module is worn out.

Set pump up correctly.

Set pump up correctly.

Change the process.

Add oil.

Change the oil.

Clean or repair the oil lines and channels.

Replace the exhaust filter, clean the exhaust line.

Repair the valve.

Replace the pump module.

Oil is turbid. Condensation. Degas the oil or change the oil and clean the pump. Precau-

tion: open the gas ballast valve or insert a condensate trap.

2.5.2/3.2

2.1

2.1/2.5.3

-

3.2

3.2

Service

-

Service

3.7

Pump is excessively

noisy.

Oil level is much too low (oil is no longer visible).

Silencing nozzle is clogged.

Intake pressure is too high.

Internal demister is clogged.

Coupling element is worn.

Vanes or bearings are damaged.

Add oil.

Clean or replace the silencing nozzle.

Lower the intake pressure.

Clean or replace demister.

Install new coupling element.

Repair pump.

3.2

Service

-

3.4

3.5

Service

After switching off

pump under

vacuum, pressure in

system rises too

fast.

System has a leak.

Anti-suckback valve is malfunctioning.

Check the system.

Repair the valve.

-

Service

Oil in the intake line

or in vacuum

vessel.

Oil comes from the vacuum system.

Anti-suckback valve is obstructed.

Sealing surfaces of anti-suckback valve are damaged or dirty.

Oil level is too high.

Check the vacuum system.

Clean or repair the valve.

Clean or repair the intake port and the anti-suckback valve.

Drain the excess oil.

-

Service

Service

3.2

* Repair information: refer to the Section in the Operation Instruction stated here.

1) Bubble test: the warm pump with degassed oil is running without gas ballast and the intake blanked off.The exhaust line is led in to a vessel with water. If an evenly

spaced line of bubbles appears, then the pump has an external leak.

25

Troubleshooting

Loading...

Loading...