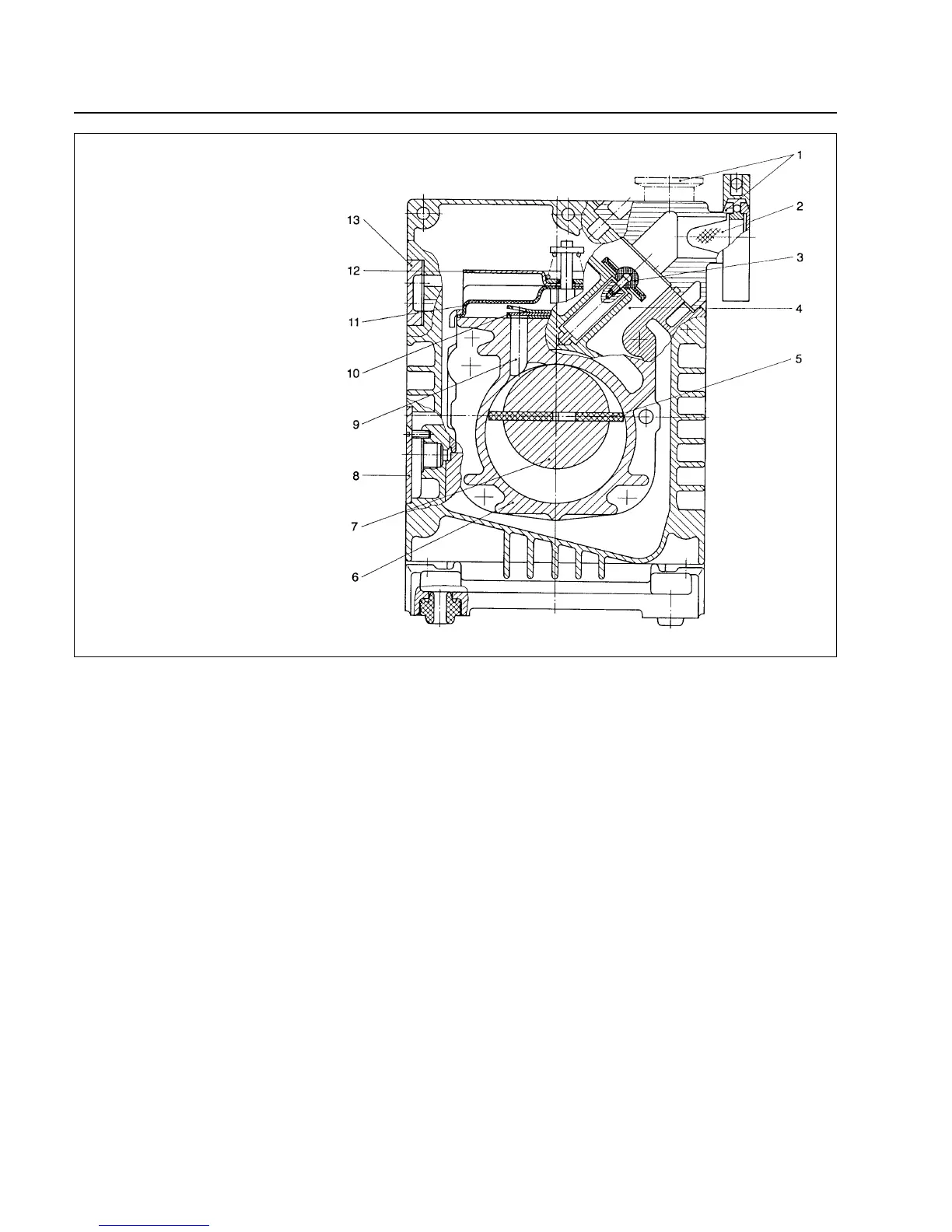

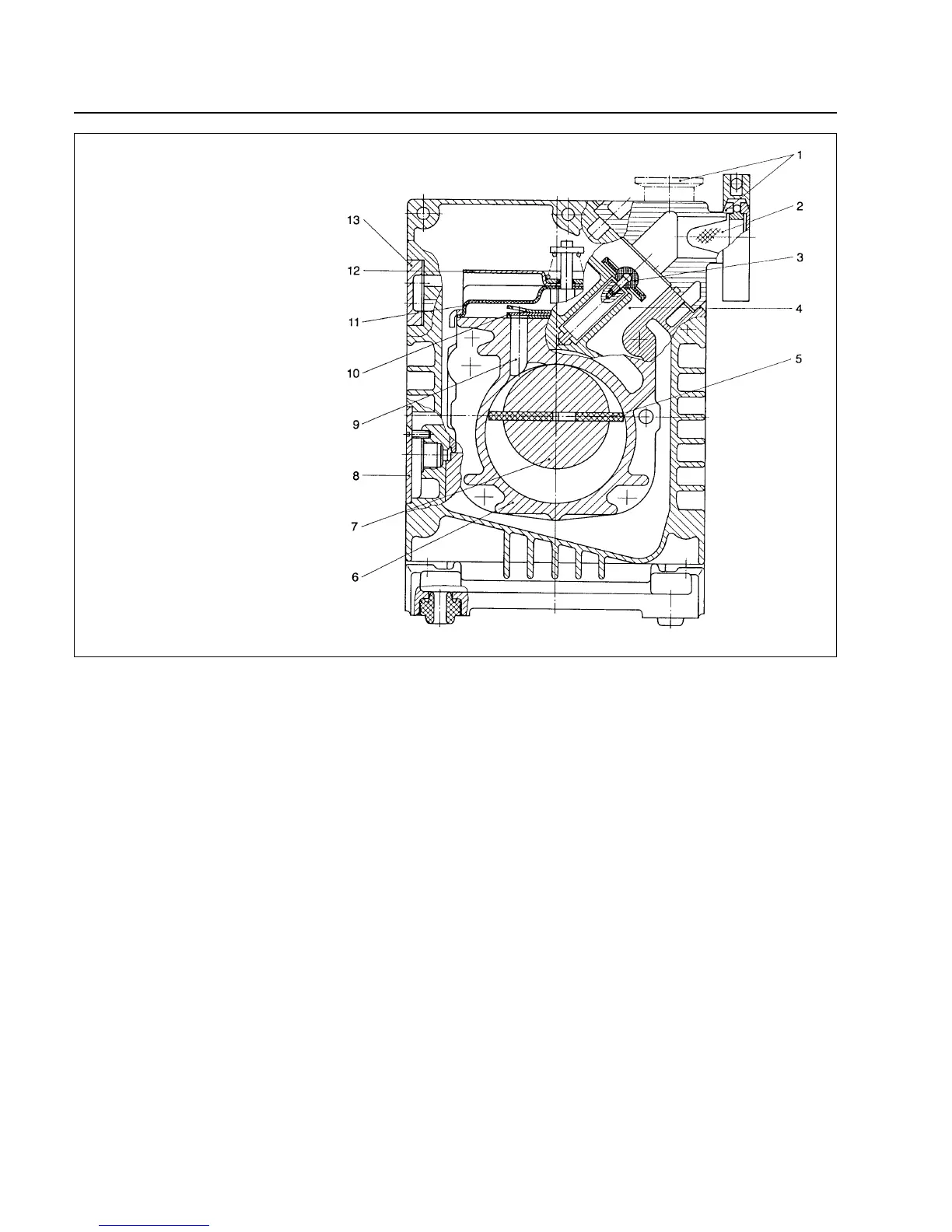

1.1 Function

The rotor (2/7), mounted eccentrically in the pump

housing (2/6), has two radially sliding vanes (2/5) which

divide the pump chamber into several compartments.

The volume of each compartment changes periodically

with the rotation of the rotor.

As a result, gas is sucked in at the intake port (2/1). The

gas passes through the dirt trap sieve (2/2), flows past

the open anti-suckback valve (2/3) and then enters the

pump chamber. In the pump chamber, the gas is passed

on and compressed, after the inlet aperture is closed by

the vane.

The oil injected into the pump chamber is used for

sealing and lubricating. The slap noise of the oil in the

pump which usually occurs when attaining the ultimate

pressure is prevented by admitting a very small amount

of air into the pump chamber.

The compressed gas in the pump chamber is ejected

through the exhaust valve (2/10). The oil entrained in the

gas is coarsely trapped in the internal demister (2/11);

there the oil is also freed of mechanical impurities. The

gas leaves the TRIVAC B through the exhaust port.

Description

During compression, a controlled amount of air – the so-

called gas ballast – can be allowed to enter the pump

chamber by opening the gas ballast valve. The gas

ballast stops condensation of vapours in the pump

chamber up to the limit of the water vapour tolerance as

specified in the technical data for the pump.

The gas ballast valve is opened and closed by turning

the gas ballast knob (7/5) on the front.

To enable the TRIVAC B to be used at intake pressures

as high as 1,000 mbar, a special lubricating system was

developed featuring force-lubrication of the sliding

bearings.

An oil pump (3/6) pumps the oil from the oil reservoir

(3/5) into a pressure-lubrication system which supplies

oil to all bearing points (3/2). From there the oil enters the

pump chamber area (3/4) of the vacuum pump.

The oil pump is fitted in the front end plate on the

coupling side of the pump module. The oil suction line is

placed low, resulting in a large usable oil reservoir.

4

Fig. 2 Sectional drawing of the TRIVAC B

Key to Fig. 2

1 Intake port

2 Dirt trap

3 Anti-suckback valve

4 Intake channel

5 Vanes

6 Pump chamber

7 Rotor

8 Cover plate, connection for inert gas ballast

9 Exhaust channel

10 Exhaust valve

11 Internal demister

12 Spring buckles

13 Cover plate, connection for oil filter

Loading...

Loading...