26

DATE

22.12.2003

COMPILER TECO/ATI

REG. CODE

1-5302-467

MODEL N°

50707

DATE OF ISSUE

06-95

REVISION 05

ENDORSED

VIII

20

18

19

DISASSEMBLY/REASSEMBLY

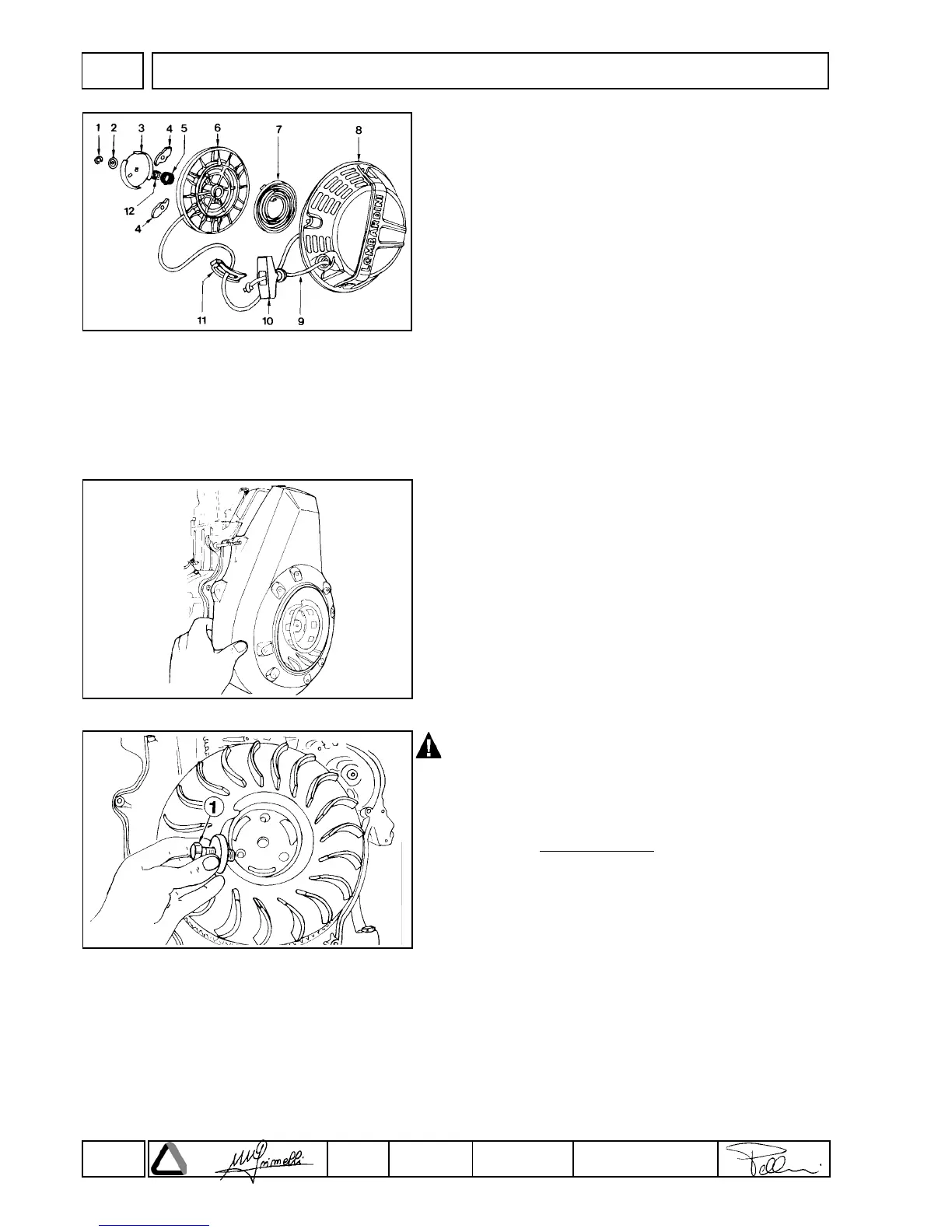

Re-coil starting

Operation:

When pulling handle 10, thanks to the action of friction spring 12,

teeth 4 protrude from cap 3. After starting these teeth go back to the

initial position because the cap rotates. Rope 9 is re-wound around

pulley 6 by means of spring 7.

Components:

1 Retainer 7 Spring

2 Washer 8 Guard

3 Cap 9 Rope

4 Flyweights 10 Handle

5 Spring 11 Rope guide

6 Pulley 12 Spring

Note: there are two kinds of guards 8, one for engines with an rpm

above 2000 and one with fewer cooling channels for engines

with a lower rpm

On reassembly, tighten the screws to 10Nm.

Shroud

The shroud and the metal sheeting outside the cylinder are made of

special material (ANTIPHON) which absorbs noise, thus reducing

total engine sound pressure levels.

When refitting tighten shroud screws to 10 Nm.

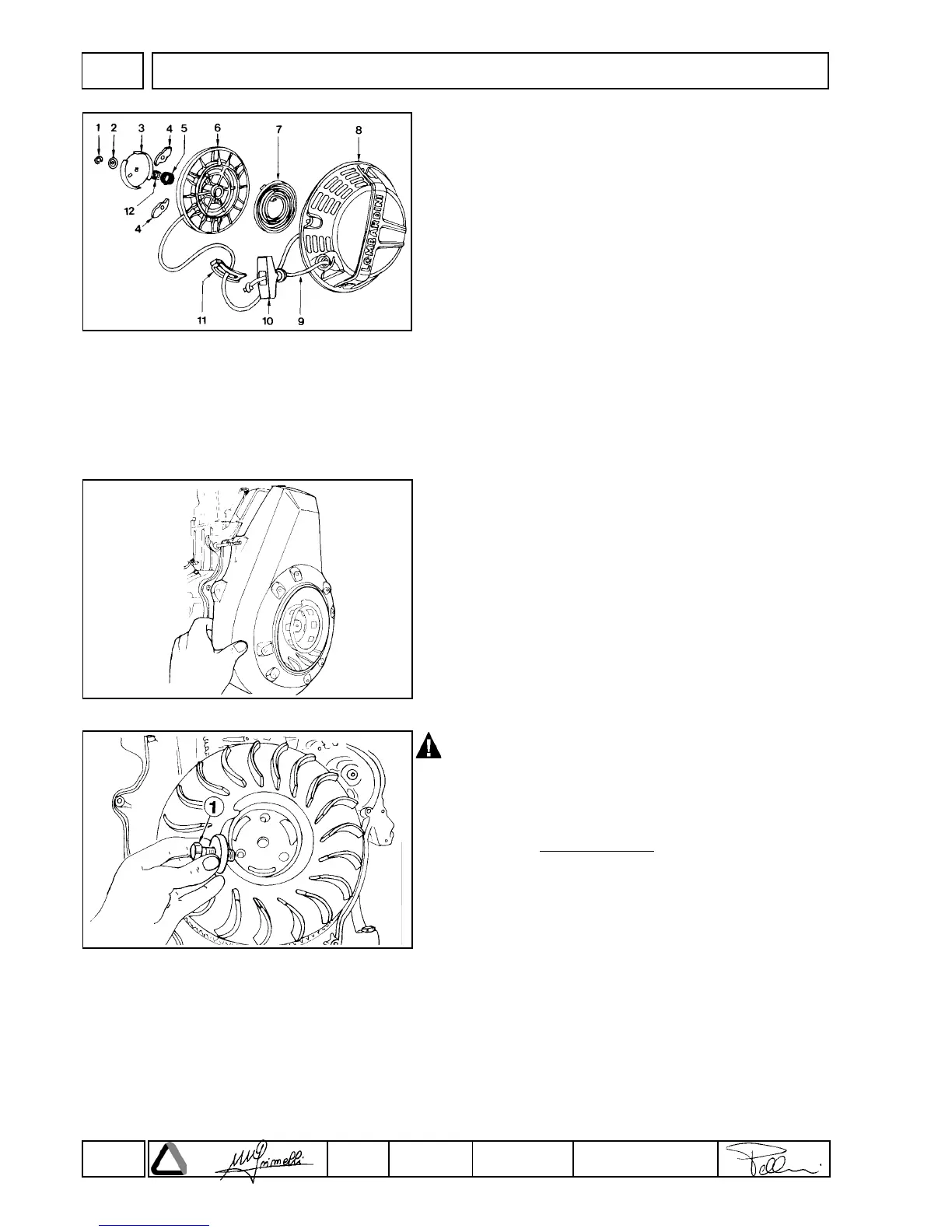

During the demounting phases, pay particular attention to

prevent the flywheel from dropping as this could seriously

injure the operator.

Wear protective goggles when removing the flywheel ring.

Flywheel

Unscrew bolt 1 in a clockwise direction.

Remove the flywheel with a puller.

Make sure that the tapered surface that couples to the drive shaft is

not damaged.

To remove the starter rim, it is advisable to cut it into several parts

with a hacksaw and to then use a chisel. To replace, slowly heat for

15-20 minutes to a temperature of 300°C max.

Fit the rim into the flywheel housing. make sure that it rests evenly

against the support of the housing itself.

Allow it to slowly cool.

When refitting tighten bolt 1 to 150 Nm.

See pages 34 and 35 for injection timing reference marks.

Loading...

Loading...