59

DATE

22.12.2003

COMPILER TECO/ATI

REG. CODE

1-5302-467

MODEL N°

50707

DATE OF ISSUE

06-95

REVISION 05

ENDORSED

X

121

120

FUEL SYSTEM

Injector calibration

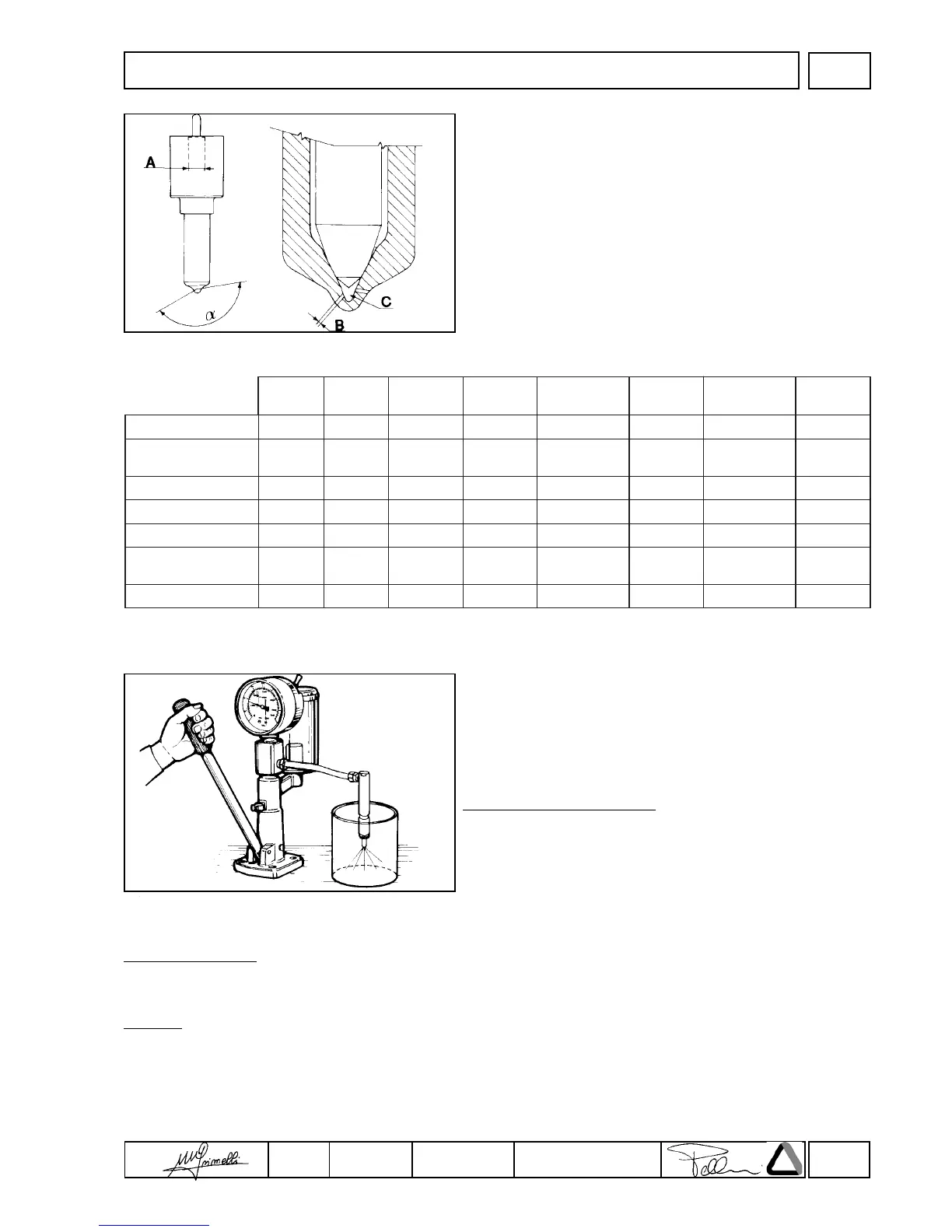

Connect the injector to a hand pump and adjust if necessary,

modifying the thickness above the spring.

When the spring is replaced, calibration must be carried out at a

pressure higher than 10 bars to counterbalance adjustments while

running.

Spraying and opening pressure

With the pressure gauge closed, press hard on the hand pump at

least 10 times.

Open the pressure gauge and press down on the pump once every

second, while keeping a check on the spraying process and

pressure.

The opening pressure must lie between the two values given in the

table. Jets must be uniform and well distributed.

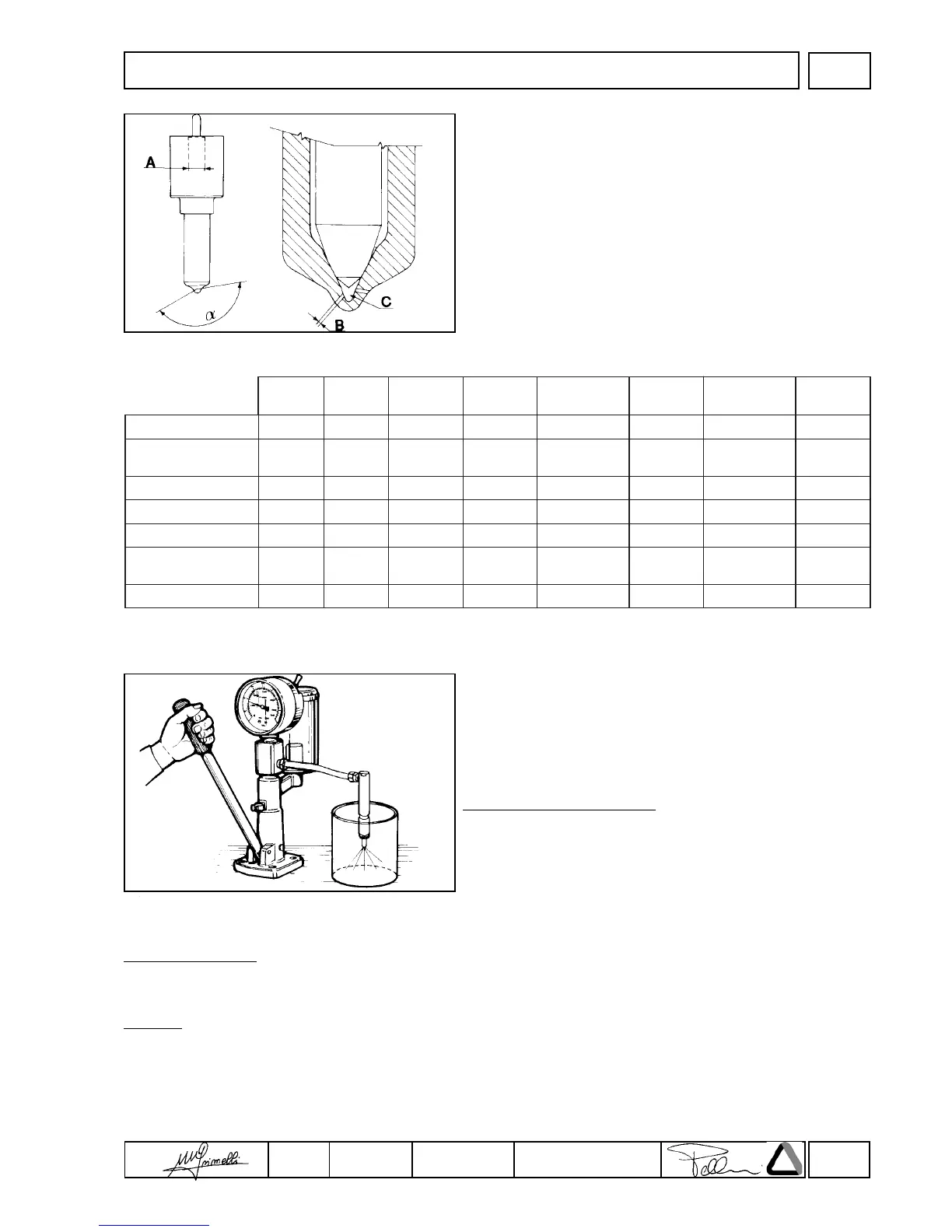

Nozzles

The set-up between the needle and the guide must leave the

needle free to fall and merely as a result of its own weight, when

lifted 7mm from its seat and rotated in different directions, with the

nozzle kept at a 45° angle.

Rotation of the needle must be completely smooth and uninhibited

by obstacles and malformations.

Moreover, on being squeezed against its seat, it must fall freely,

when the nozzle is inverted.

The test must be carried out after rinsing both the needle and

nozzle with trichloroethane and wetting with filtered SHELL

CALIBRATION FLUID “C” oil.

522DL51513DL51

513DL51

APE

053DL51APE053DL51004DL51

004DL51

APE

044DL51

A

5,45,45,45,45,45,45,45,4

B

selohfo.maiddna°N(

71,0x402,0x4141,0x522,0x4051,0x5951,0x5051,0x5661,0x5

htgneleloh5,06,08,06,08,05,08,05,0

αα

α

αα

°061°061°551°061°551°061°061°061

thgiehnip51,0÷01,051,0÷01,0522,0÷571,0571,0÷521,0522,0÷571,0524,0÷573,0524,0÷573,0524,0÷573,0

C

emulovpmus

³mm63,0³mm63,0³mm0³mm63,0³mm0³mm91,0³mm0³mm91,0

*)rab(erusserP4±4124±4126±0424±4126±0424±0024±9524±002

Leakage time (waste)

Pressure must drop from 150 to 100 bars in a span of not less than 8 seconds and not more than 30.

Seat seal

Nozzle tip wet.

Pressure must be kept 20 bars below the opening pressure for 10 seconds.

After this time, dampness on the nozzle tip is acceptable, and may be identified by touching with a dry finger. Only a drop of

dampness is acceptable and not a large thick patch which would indicate a leak.

* These values apply to new injector and allow for loosening of up to10% after breaking-in period

Loading...

Loading...