43

DATE

22.12.2003

COMPILER TECO/ATI

REG. CODE

1-5302-467

MODEL N°

50707

DATE OF ISSUE

06-95

REVISION 05

ENDORSED

VIII

74 75

73

DISASSEMBLY/REASSEMBLY

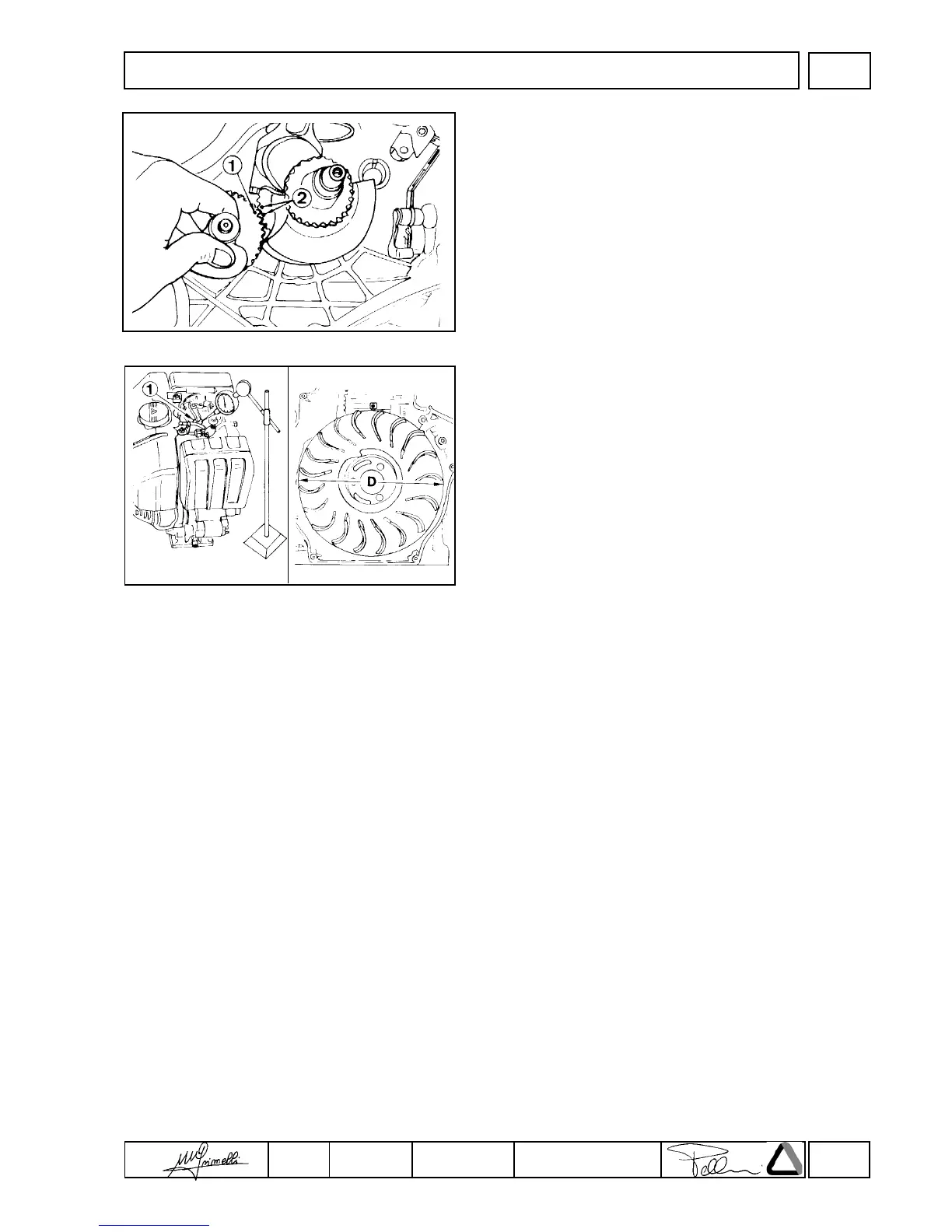

Dinamic balancer timing

Position crankshaft as shown in the figure.

Introduce the dynamic balancer so that timing mark 1 engages

between teeth 2 of the crankshaft gear.

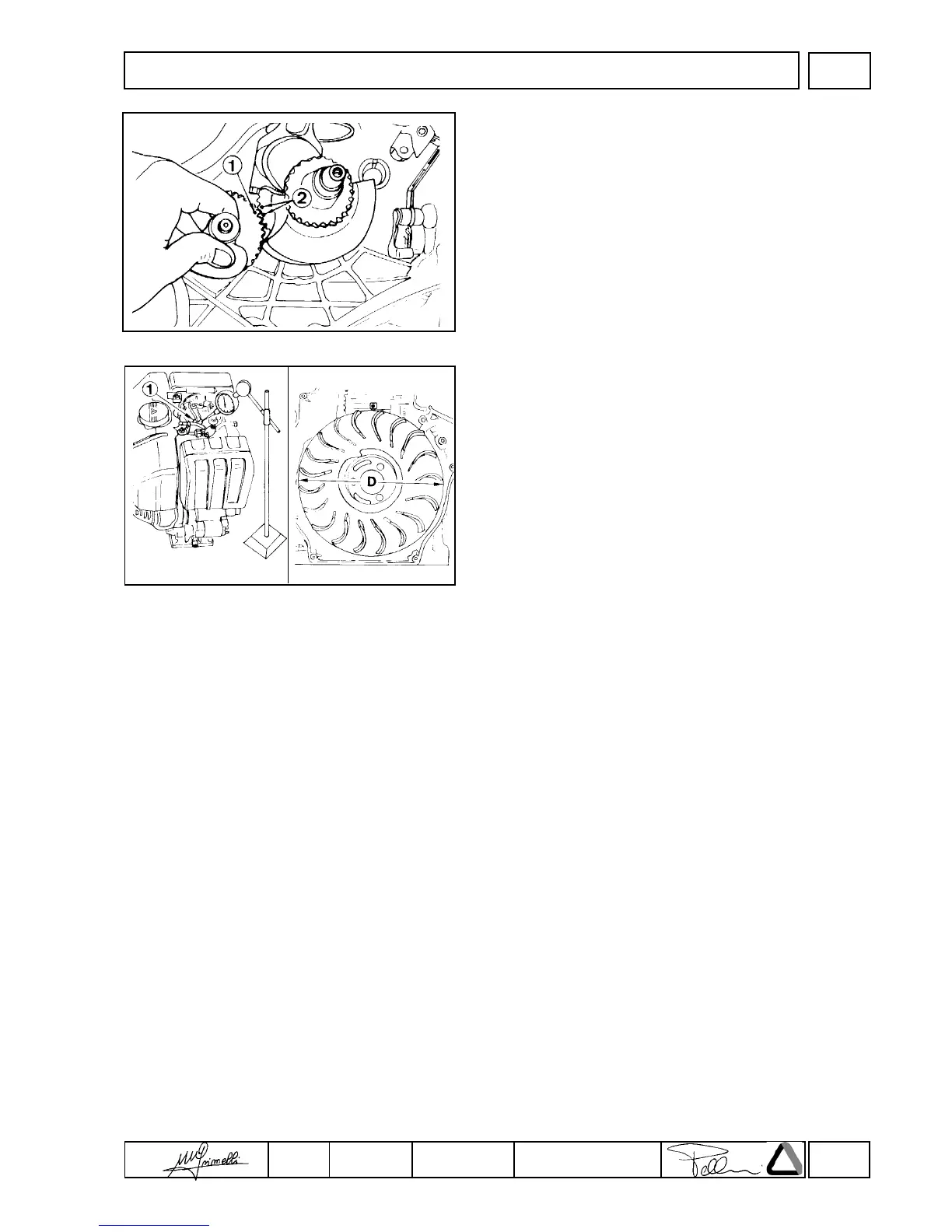

Valve timing check

Remove the tank and conveyor to access the flywheel.

Carry out the inspections on the drive shaft. The values given are

measured on the circumference of the flywheel.

Adjust the valve play as indicated on the next page.

Reset the comparator on the cap of intake valve 1. Turn the drive

shaft in the spinning direction and find

αα

αα

α (point at which the intake

valve starts to open in relation to top dead center A) and

β β

β β

β (point at

which the intake valve shuts after bottom dead center B) see fig. 77-

78.

Proceed in a similar way with the exhaust valve, checking

γγ

γγ

γ (point at

which the exhaust valve opens) and

δδ

δδ

δ (point at which the exhaust

valve shuts).

Loading...

Loading...