Alternator Inspection

Perkins recommends a scheduled inspection of

the alternator.

Inspect the alternator for loose connections and

.

Inspect the ammeter(If equipped) during engine

operation in order to ensure proper battery

performance and/or proper performance of the

electrical system.

Make repairs, as required.

Check the alternator and the battery charger for

proper operation.

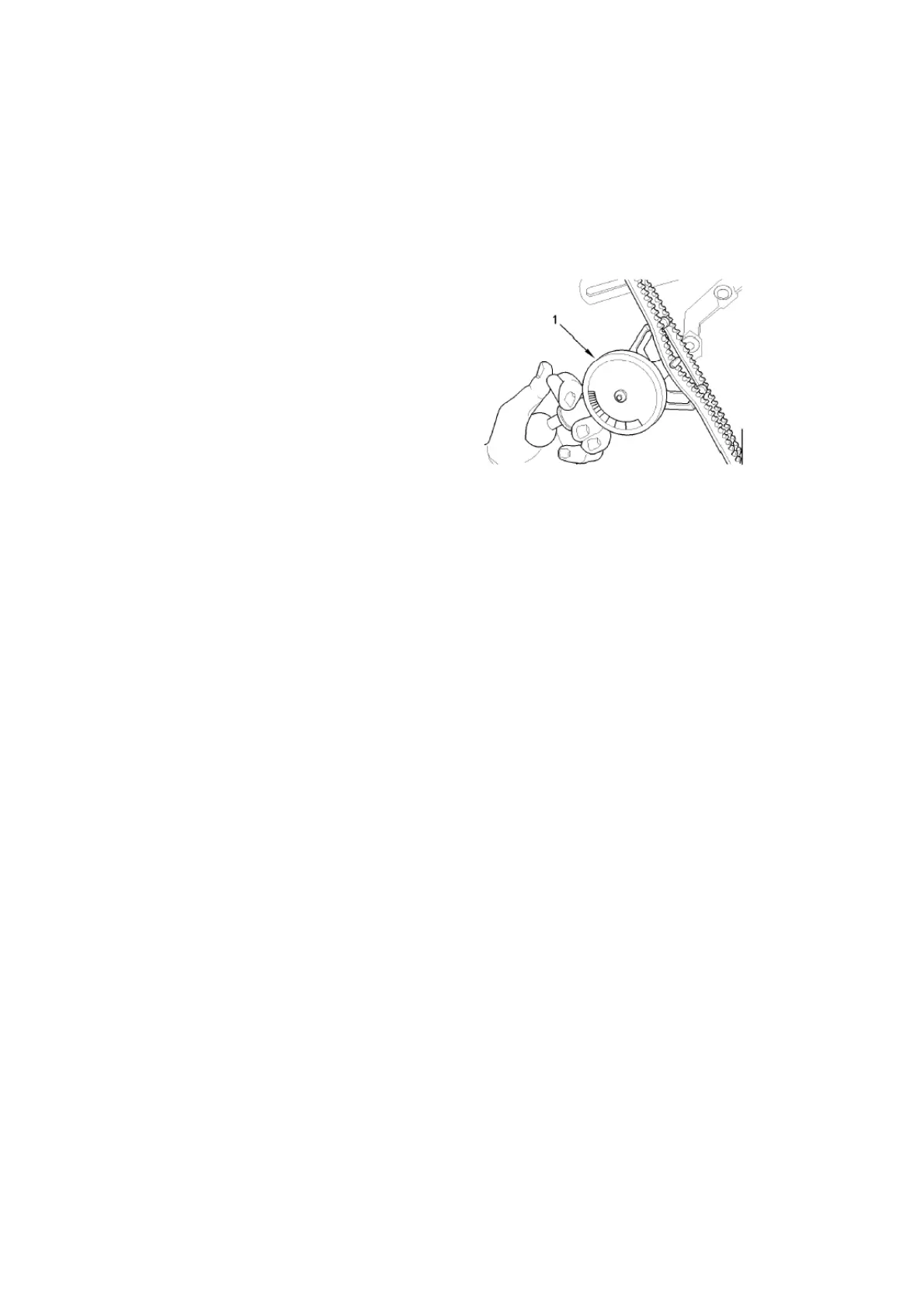

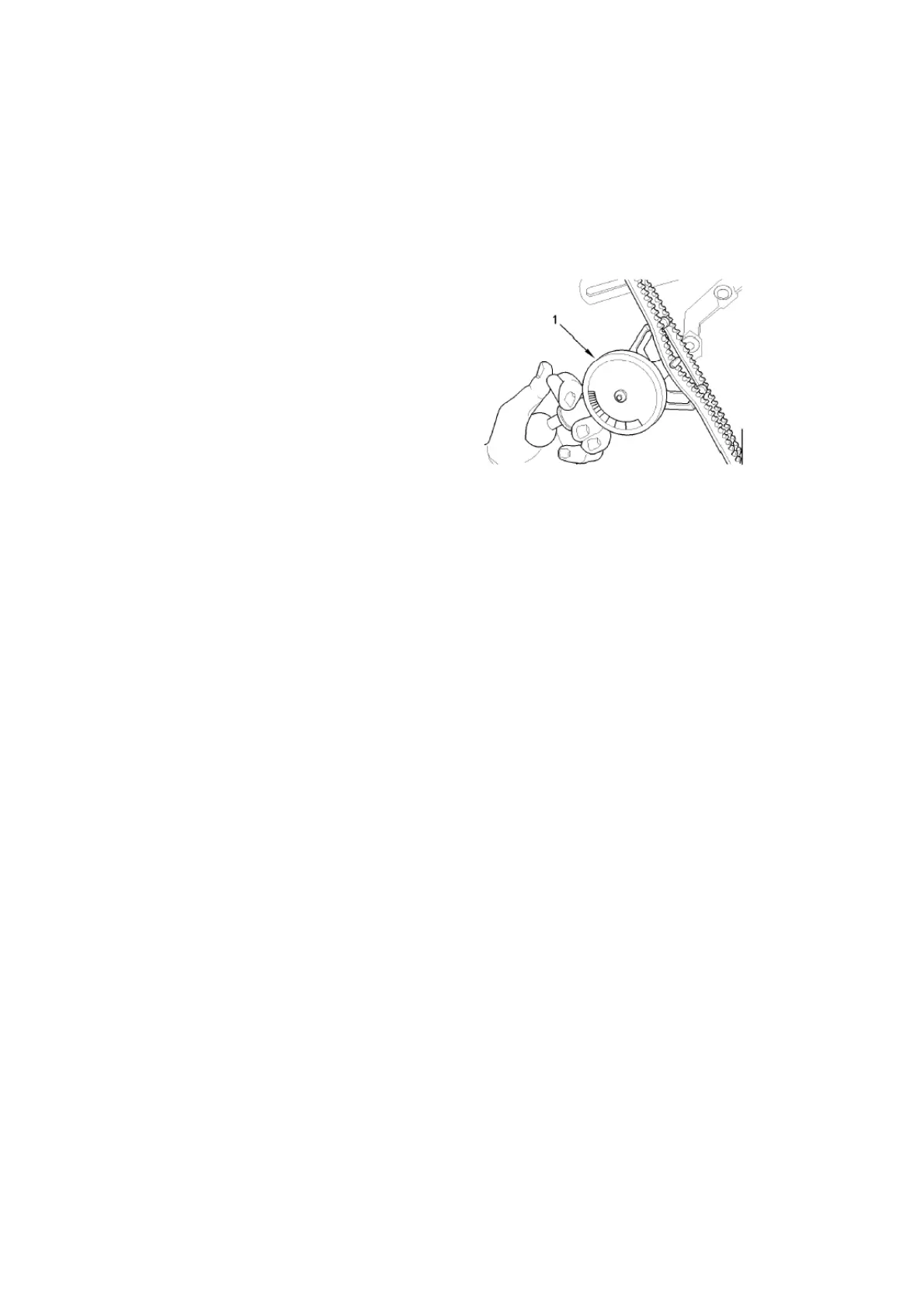

(1) Burroughs gauge.

If the batteries are properly charged, the ammeter

reading should be very near Zero.

All batteries should be kept warm because

temperature affects the cranking power.

If the battery is too cold, the battery will not crank

the engine.

When the engine is not run for long periods of time

or if the engine is run for short periods.

Fit the gauge(1) at the center of the longest free

length and check the tension.The correct

tension is 535N(120 lb).If the tension of the

belt is below 250N(56 lb) adjust the belt to 535

N (120 lb).

If twin belts are installed,check and adjust the

tension on the both belts.

e

a

ery may no

u

y c

arge

.

A battery with a low charge will freeze more easily

than a battery with a full charge.

Alternator and Fan Belts

Inspect Adjust Replace

For applications that require multiple drive belts,

replace the belts in matched sets.

Replacing only one belt of a matched set will cause

the new belt to carry more load because the older

belt is stretched.

The additional load on the new belt could cause

the new belt to break.

If the belts are too loose.

77

v

rat

on causes unnecessary wear on t

e

e

ts an

pulleys.

Loose belt may slip enough to cause overheating.

To accurately check the belt tension,a suitable

gauge should be used.

Loading...

Loading...