P 4/ 18

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-1. Warning

[4]-2. Separation of Shaft from Engine

DISASSEMBLING

ASSEMBLING

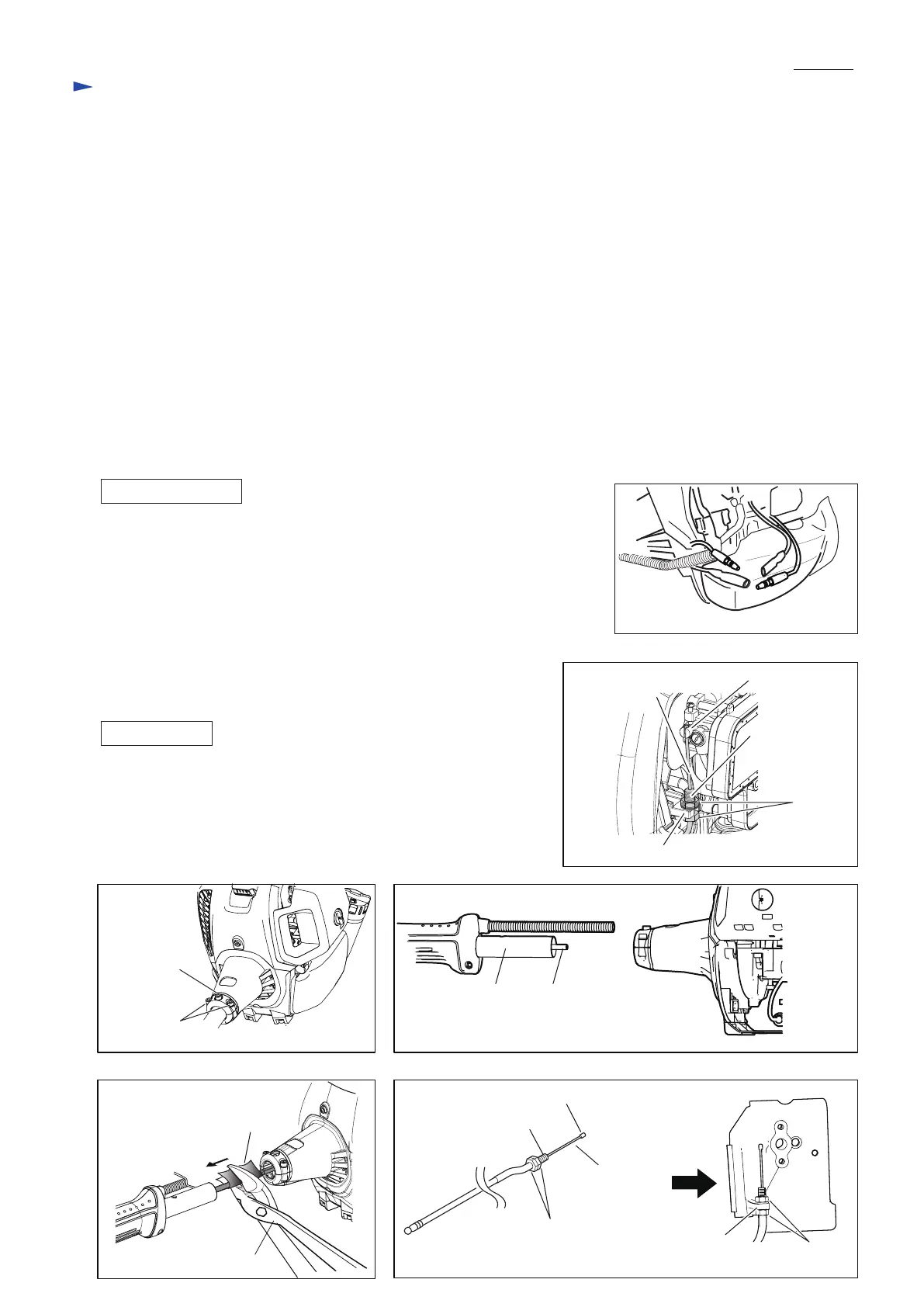

(1) Disconnect lead wire and grounding wire by removing each connector

after removal of Air cleaner cover. (Fig. 2)

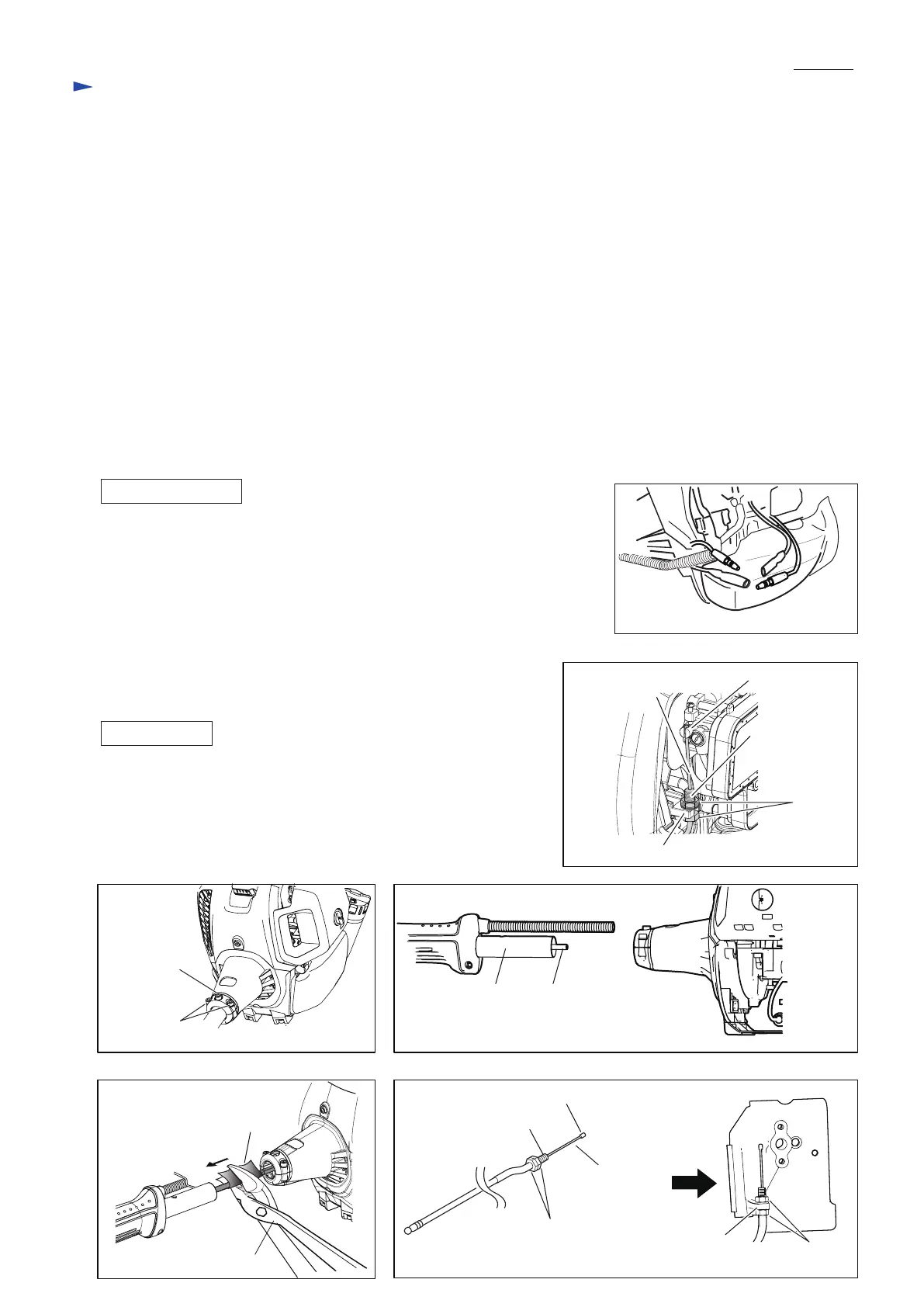

(2) Remove Control cable from Insulator by loosening the adjust screw (Fig. 3)

then by disconnecting the inner cable from Swivel of Carburetor.

(3) Loosen two M5x18 Hex socket head bolts on Pipe holder and remove M5x12

Hex socket head bolt. (Fig. 4)

(4) Pull Pipe complete and Shaft out of Engine (Pipe holder). (Fig. 5)

Note: Shaft in Pipe complete may get stuck at the spline engagement.

Use Water pump pliers to pull out the shaft covered with a rag.

(Fig. 6)

Assemble by reversing the disassembly procedure.

• Set Control cable in place as follows; (Figs. 3 and 7)

- Secure it on the projection of Insulator with two Nuts of Control cable.

- Fit the hook of Inner cable end into the groove of Swivel of Carburetor.

Note: Adjust the tension of the cable to allow the play 1mm up to 2mm.

Fig. 2

Inner cable of

Control cable

Inner cable of

Control cable

Swivel

Adjust screw

Projection of Insulator

Pipe complete Shaft

Nuts

M5x18 Hex.

socket head bolt (2pcs.)

M5x12 Hex.

socket head bolt

Fig. 4

Fig. 6 Fig. 7

Fig. 5

Fig. 3

Connector (4pcs.)

Adjust screw

Projection

of Insulator

Swivel

Nuts

Nuts to fix on the projection

of Insulator

Water pump pliers

Rag

Follow the instructions described below in advance before repairing:

• Wear gloves.

• Attach the blade cover to the blade.

• When the engine is hot from use, cool down the engine enough or you can get burned.

• Remove remaining fuel from Fuel tank and Carburetor completely. [FLAMMABLE MATERIAL KEEP FIRE AWAY]

• Remove Spark plug cap from Spark plug.

• Repair the engine on a stable workbench and in a clean workplace kept as free of dust and debris as possible.

• In order to avoid wrong reassembly, draw or write down where and how the parts are assembled, and what are the parts.

It is also recommended to have boxes ready to keep disassembled parts by group.

• Handle the disassembled parts carefully. Clean and wash them properly.

• If some bolts and screws are too tight, use an impact driver.

• Tighten the bolts and the screws to the specified torque as shown in "[4]-15. Tightening torque specifications".

• Each time after you mounted a main part of the engine such as the piston, check if it moves smoothly

without abnormal noise by manually turning the crankshaft.

• After completion of reassembly, check for loose parts or abnormal noise and vibration by manually turning the crankshaft.

Loading...

Loading...