P 9/ 18

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-5. Trimmer head ass’y (cont.)

Assemble by reversing the disassembly procedure. Be careful to the following points.

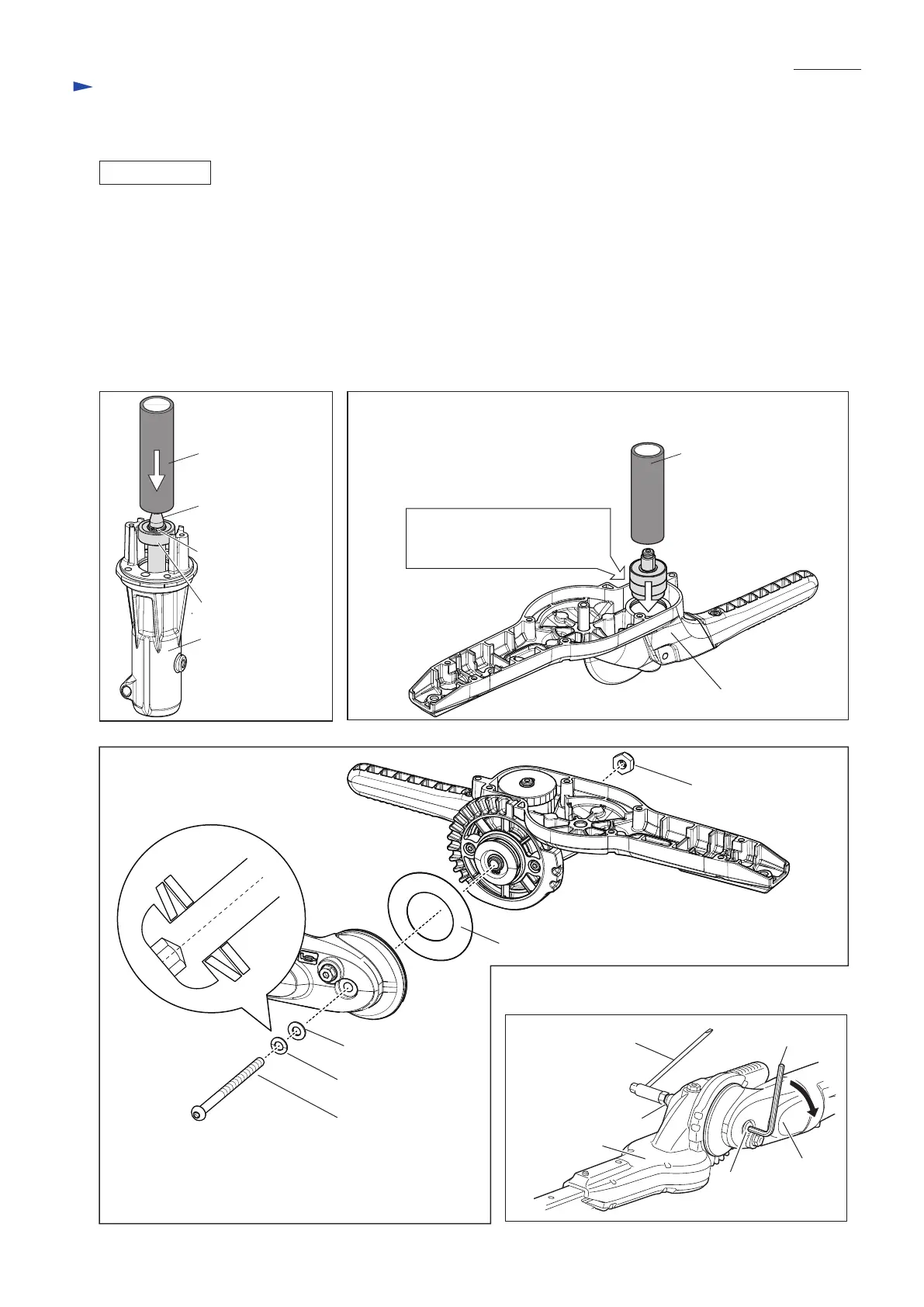

• Press-fit Spindle complete into Pipe holder with 1R029. (Fig. 30)

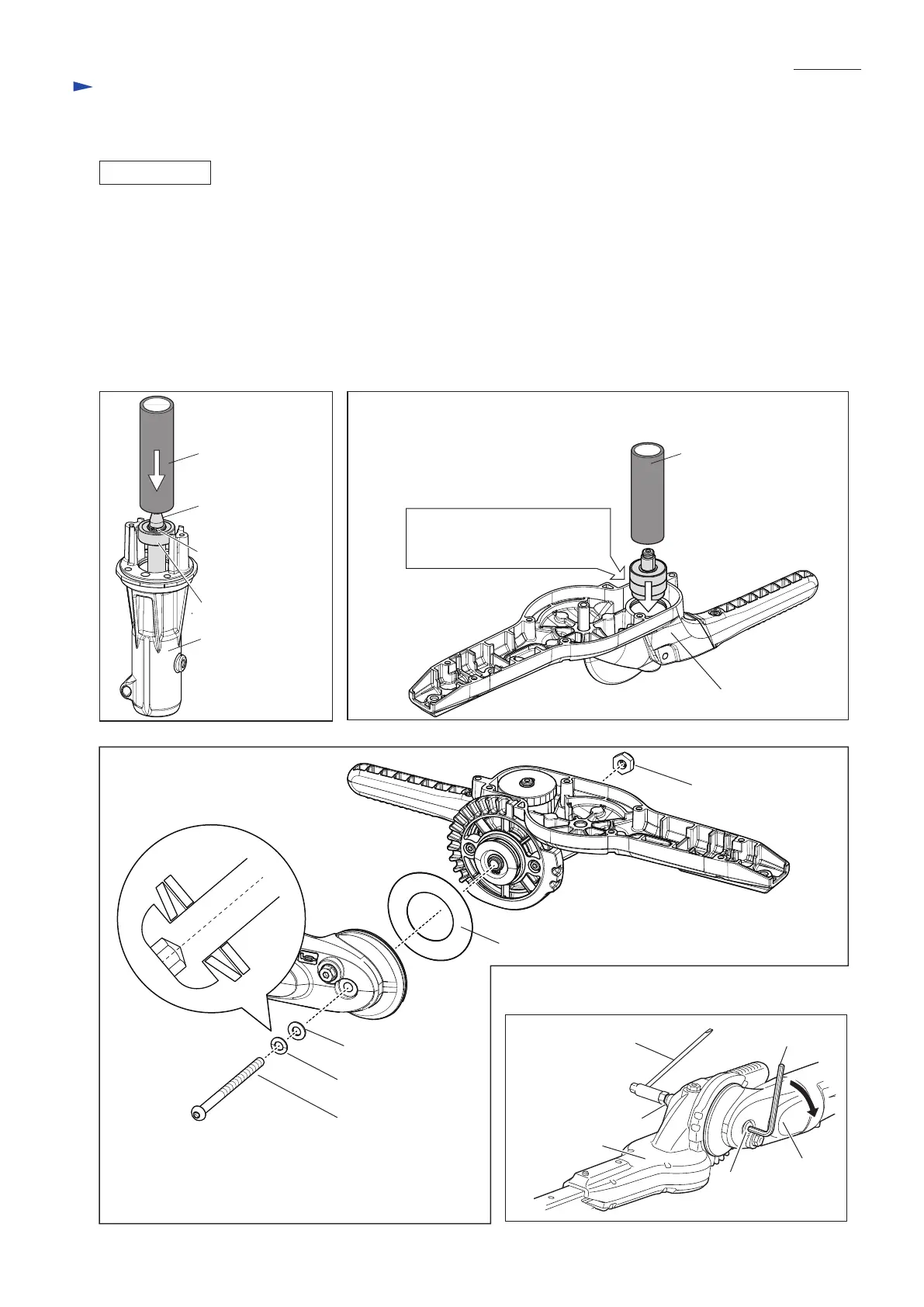

• Press-fit the module of Spiral bevel gear 12 and two Ball bearings 6000ZZ into Gear housing with 1R030. (Fig. 31)

• Attach the convex portion of Coned disc spring 6 to the bolt head of M6x85 Hex socket button head bolt, then pile Flat

washer 6 on Coned disc spring 6, and last, fasten Joint to Gear housing complete with M6-10 Hex lock nut and M6x85

Hex socket button head bolt. (Fig. 32)

• After adjusting the tightening torque of M6x85 Hex socket button head bolt so that Joint and Gear housing can be set to

the desired angle without any backlash, secure them firmly by tightening M6-10 Hex lock nut with Box driver 10-16 and

Wrench 4 supplied as standard equipment. (Fig. 33)

Fig. 30

Pipe holder

1R029

Fig. 32

Fig. 31

ASSEMBLING

1R030

Gear housing

Spindle complete

Module of

Spiral bevel gear 12

and two Ball bearings 6000ZZ

Retaining ring S-9

Ball bearing 609ZZ

M6-10 Hex lock nut

Gear housing

section

Coned disc spring 6

Joint section

Flat washer 6

Flat washer 36

M6x85 Hex socket button head bolt

Fig. 33

Wrench 4

Joint

M6-10 Hex lock nut

Box driver 10-16

Gear housing

complete

M6x85 Hex socket

button head bolt

Loading...

Loading...