Installation and Commissioning

46

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

6.4.2 Checking crankshaft axial clearance

NOTE

The engines' crankshaft axial clearance specified in the design must not be reduced under any circum

stances as a result of mounting clutches or other attachments.

For this reason:

S It is essential to determine the crankshaft axial clearance using a dial gauge held on a magnetic stand

before and after flange-mounting any attachments.

S Remove V-belt protection.

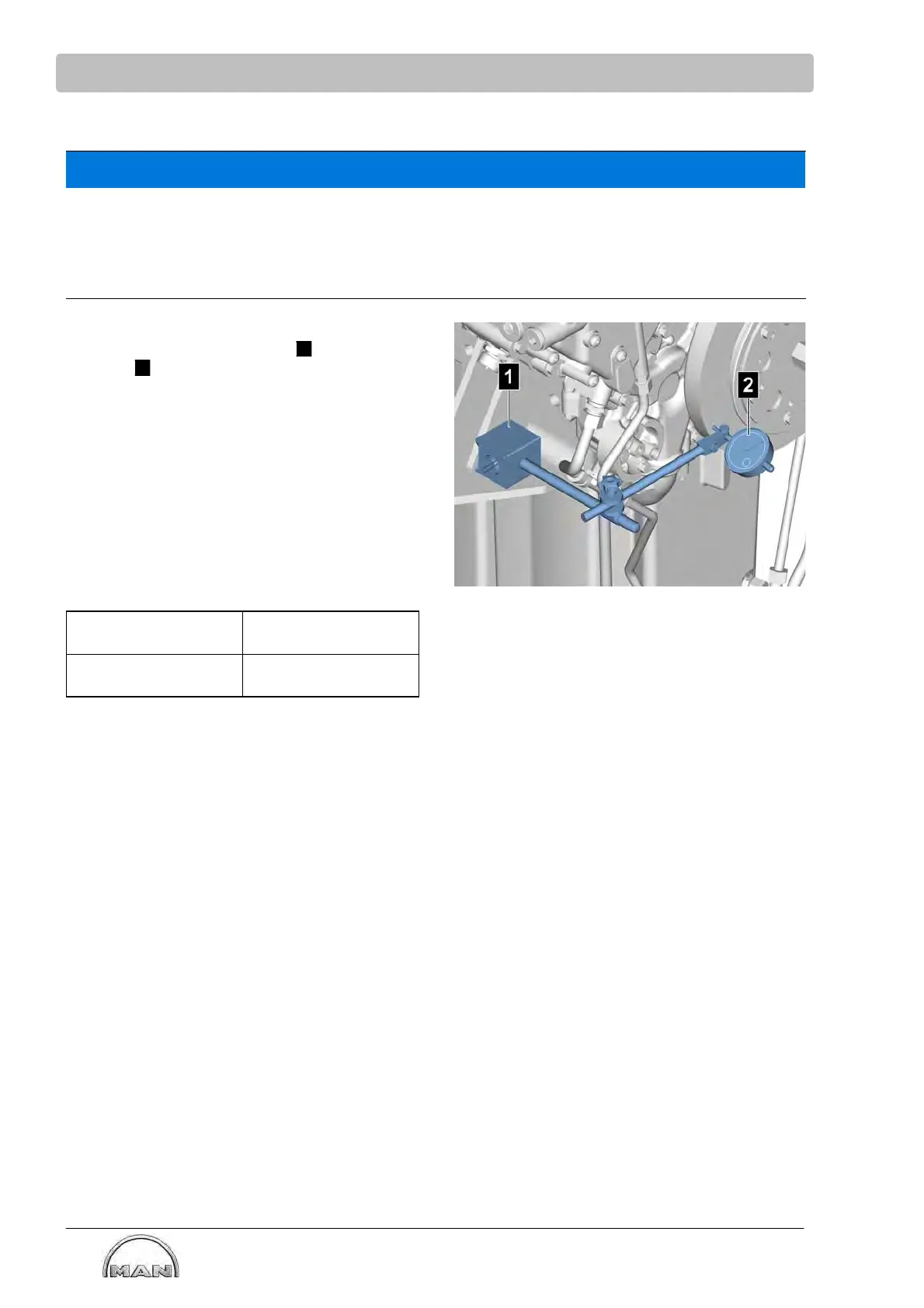

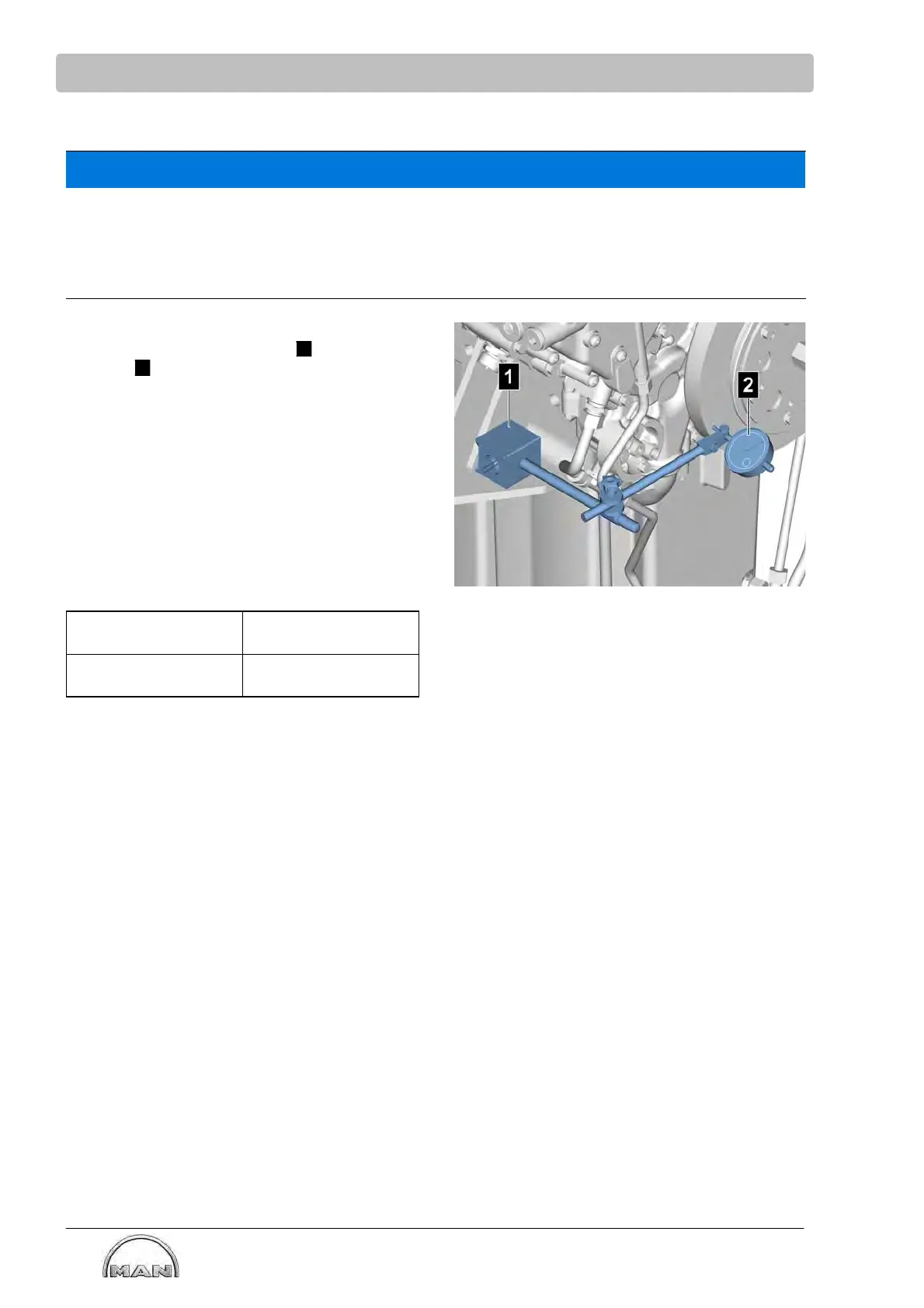

S Position the dial gauge holder

1

with dial

gauge

2

on the engine mounting so that the

dial gauge tracer pin is resting on the vibration

damper with a preload.

S Push the crankshaft towards the flywheel hou

sing in axial direction until the stop is reached.

S Zero the dial gauge.

S Pull the crankshaft away from the flywheel hou

sing in axial direction until the stop is reached

S Check the reading on the dial gauge.

If the results of both measurements do not match,

or if the crankshaft springs back after being mo

ved, check the mounting.

Engines Crankshaft axial clea

rance

E3268LE202 /

E3262 LE202

0.20-0.40 mm

Loading...

Loading...