3 - 22

C - EVERY 250 HOURS SERVICE

Carry out the operations described previously as well as the following operations.

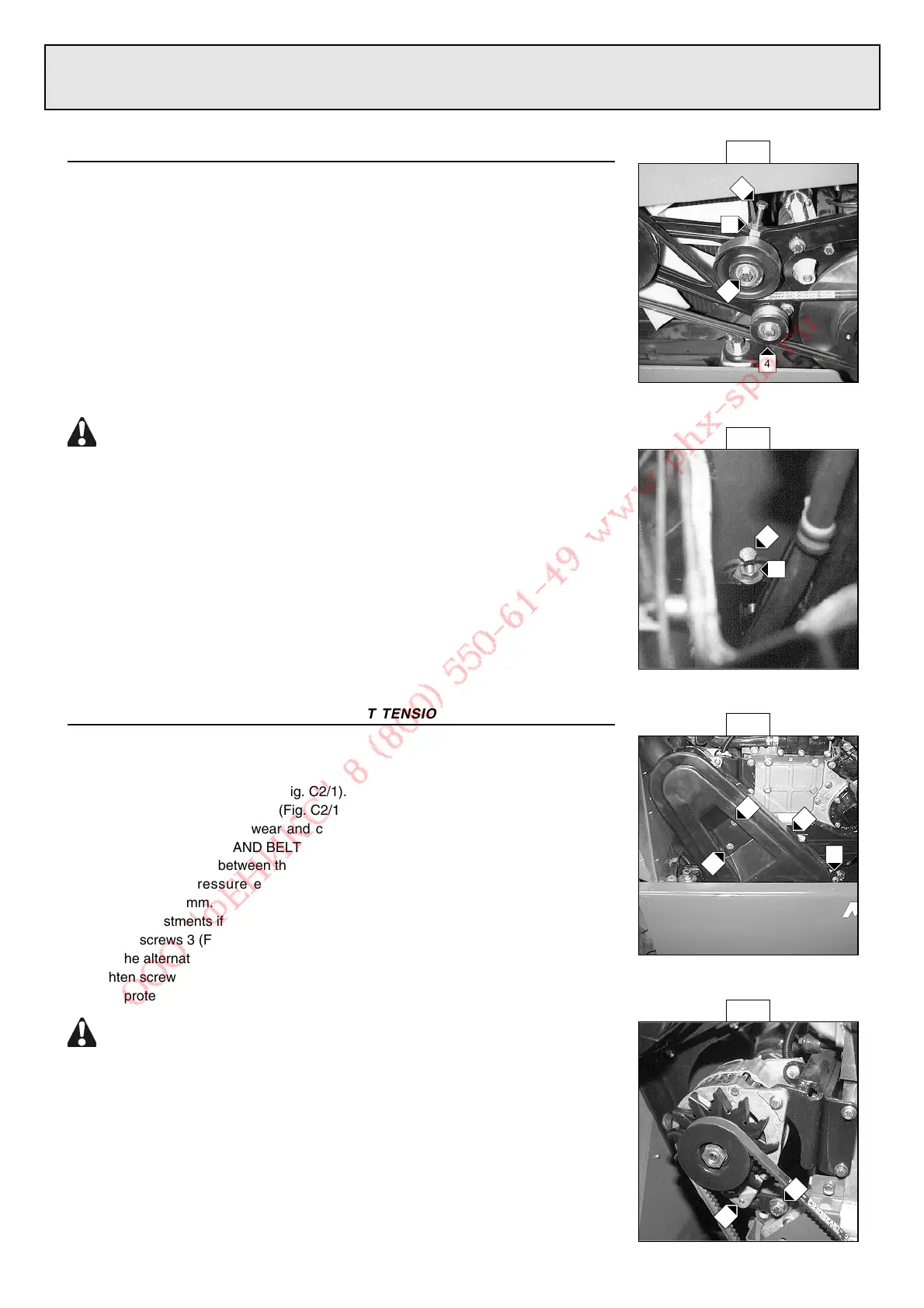

C1 - FAN BELT TENSION

CHECK - ADJUST

- Open the I.C. engine bonnet.

- Check the belt for signs of wear and cracks and change if necessary (See chapter :

FILTERS CARTRIDGES AND BELTS in paragraph : 3 - MAINTENANCE).

- Loosen screw 1 (Fig. C1/1) on the tension pulley.

- Loosen lock nut 2 (Fig. C1/1 and C1/2) and screw 3 (Fig. C1/1 and C1/2).

- Bring the belt just into contact with pulley 4 (Fig. C1/1) (On the lift truck, check this

operation by feel).

- Make a mark on the head of screw 3 (Fig. C1/1 and C1/2) and tighten, turning it 5

times.

- Tighten the lock nut 2 (Fig. C1/1 and C1/2).

- Retighten screw 1 (Fig. C1/1) on the tension pulley.

When changing the fanbelt, tighten screw 3 (Fig. C1/1 and C1/2) by one and a half

turns, having allowed the I.C. engine to idle for 30 minutes.

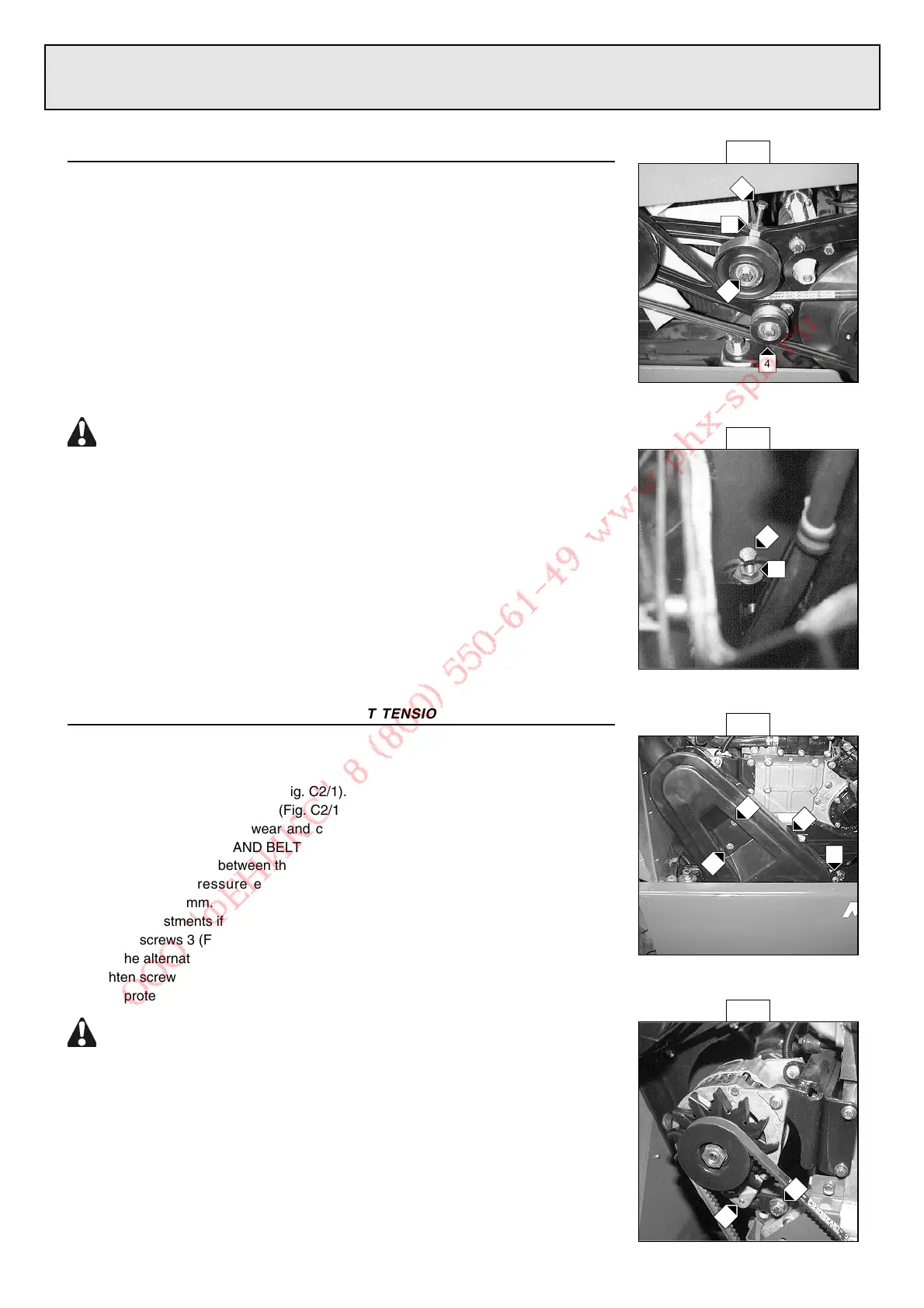

C2 - ALTERNATOR / CRANKSHAFT BELT TENSION

CHECK - ADJUST

- Open the I.C. engine bonnet.

- Unscrew the fastening screws 1 (Fig. C2/1).

- Lay down the protective guard 2 (Fig. C2/1).

- Check the belt for signs of wear and cracks and change if necessary (See chapter :

FILTERS CARTRIDGES AND BELTS in paragraph : 3 - MAINTENANCE).

- Check the belt tension between the pulleys of the crankshaft and of the alternator.

- Under a normal pressure exerted with the thumb (45N), the tension should be

approximately 10 mm.

- Carry out adjustments if necessary.

- Untighten screws 3 (Fig. C2/2) by two to three thread turns.

- Swivel the alternator assembly so as to obtain the belt tension required.

- Retighten screws 3 (Fig. C2/2).

- Put the protective guard back 2 (Fig. C2/1).

If the alternator belt has to be changed, check the tension again after the first 20

hours of operation.

C1/2

C1/1

2

3

1

2

3

4

C2/2

3

3

C2/1

1

1

1

2

Loading...

Loading...