OPERATING CONTROLS AND PROCEDURES RT9130E-2 OPERATOR MANUAL

3-42 Published 3-1-2018, Control # 559-03

converter via pump disconnect. Pump No. 4 is mounted on a

drive pad of the engine.

The purpose of these pumps is to convert mechanical

energy into fluid energy for the operation of the crane’s

hydraulic components. The pumps operate any time the

engine is running.

Control Lever Operation

The control lever operation for all crane functions is

standard, i.e. the closer the lever is to neutral (center), the

slower the system responds. The control lever should be

returned to neutral to hold the load. Never feather the hoist

control lever to hold the load.

NOTE: Always operate the control levers with slow, even

pressure.

Preload Check

After the crane has been readied for service, an operational

check of all crane functions (with no load applied) should be

performed. The Preload Check is as follows:

NOTE: Carefully read and become familiar with all crane

operating instructions before attempting a preload

check or operating the crane under load. Operate

engine at or near governed RPM during preload

check of crane functions.

1. Engage the parking brake.

2. Extend and set outriggers, and level the crane.

3. Raise, lower, and swing the boom a minimum of 45°

right and left.

4. Telescope the boom in and out.

5. Raise and lower the cable a few times at various boom

lengths. Ensure there is no kinking.

Using Your Load Chart

NOTE: One of the most important tools of every crane is

the load chart found in the crane operator cab.

The load chart contains a large amount of information, which

must be thoroughly understood by the operator.

The load chart contains outrigger capacity charts for fully

extended and mid-extended outriggers for the main boom

and jib, and fully retracted outrigger beams for main boom

only. In addition, the load chart contains two on-rubber

capacity charts: 360° stationary, and pick and carry over

front.

The capacity charts are divided into structural strength and

stability limits. This is shown by the bold line across the chart.

Capacities above the line are structural strength limits and

capacities below the line are stability limits.

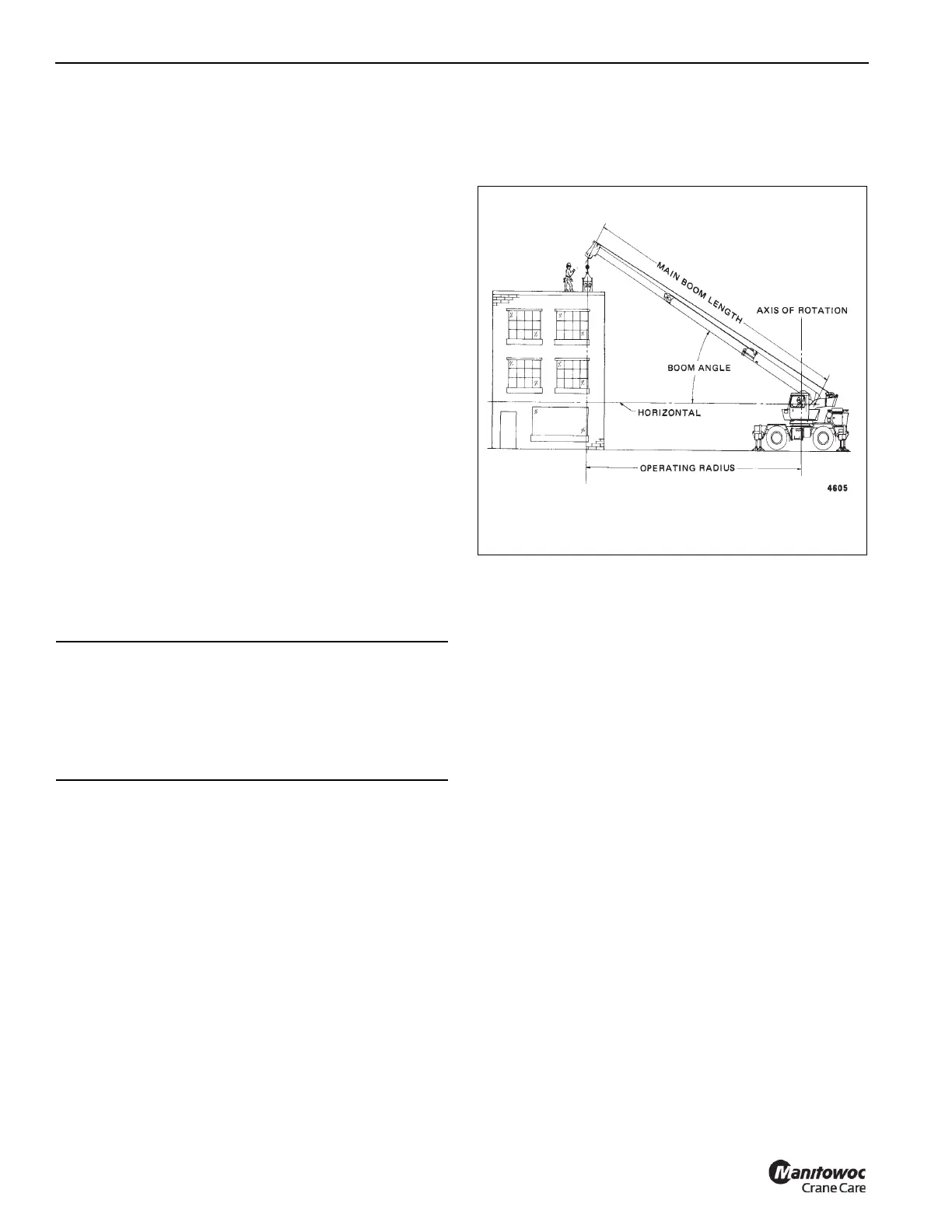

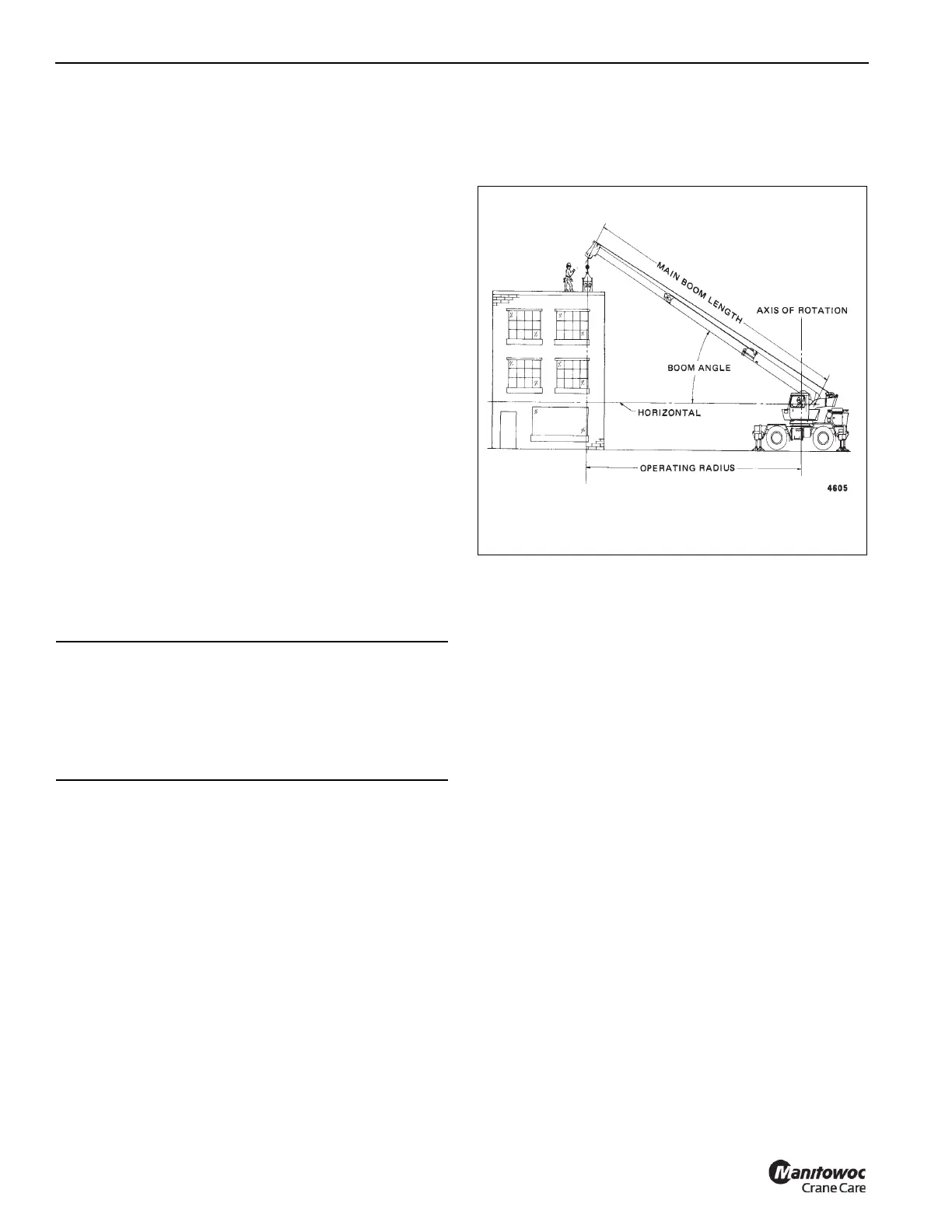

The left column is the load radius, which is the distance from

the center of crane rotation to the load center of gravity. The

top row lists various boom lengths ranging from fully

retracted to fully extended or jib lengths and offsets. The

number at the intersection of the left column and top row is

the total load capacity for that load radius and boom length or

jib lengths offset. The number in parentheses below the total

load capacity is the required boom angle (in degrees) for that

load. When the boom length or lift radius or both are between

values listed, the smallest load shown at either the next

larger radius or next longer or shorter boom length shall be

used.

Another important section is the range diagram. The range

diagram shows the operating radius and tip height that can

be achieved at a given boom length and angle. If the

operator knows the radius and tip height required for a

specific lift, the angle and boom length can be quickly

determined from the range diagram. Or, if the boom length

and angle are known, the tip height and operating radius can

be quickly determined.

A lifting diagram is included to describe over side, over rear,

and over front lifting areas. The lifting area diagram shows

that the locations of the outrigger jack cylinders in the fully

extended position are used to mark the boundaries of the

lifting areas.

CAUTION

Avoid Crane Damage!

Do not engage the parking brake while the vehicle is

moving. Damage to the crane can occur.

Disengage the parking brake before driving. Damage to

the crane can occur.

Loading...

Loading...