INTRODUCTION RT9130E-2 OPERATOR MANUAL

1-12 Published 3-1-2018, Control # 559-03

• When replacing fixed length cable assemblies (e.g.

pendants) having permanently attached end fittings use

only pre-assembled lengths of wire rope as supplied

from Manitowoc. Do not build lengths from individual

components.

• Replace an entire wire rope assembly. Do not attempt to

rework damaged wire rope or wire rope ends.

• Never electroplate wire rope assemblies.

• Do not weld any wire rope assembly or component

unless welding is recommended by the wire rope

manufacturer. Welding spatter shall never be allowed to

come in contact with the wire rope or wire rope ends. In

addition, be sure that the wire rope is not an electrical

path during other welding operations.

• Wire ropes are manufactured from special steels. If

heating a wire rope assembly is absolutely necessary for

removal, the entire wire rope assembly shall be

discarded.

• On systems equipped with two or more wire rope

assemblies operating as a matched set, they shall be

replaced as an entire set.

• Do not paint or coat wire ropes with any substance

except approved lubricants.

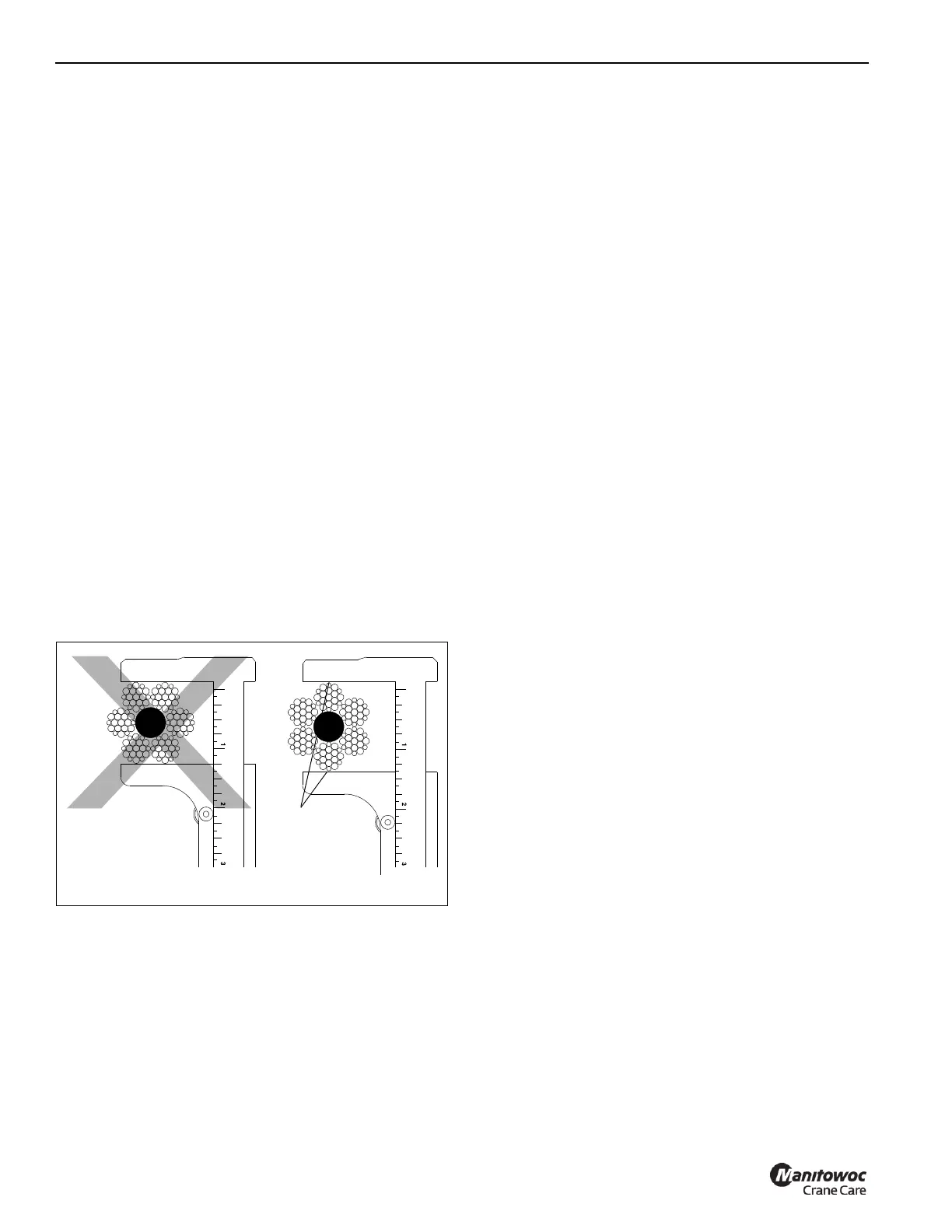

• Measure the rope’s diameter across crowns (1) of the

strands when determining if rope has become damaged

(Figure 1-5).

Wire Rope Inspection (Running Ropes and

Pendant Cables)

Wire rope should be inspected frequently/daily and

periodically/yearly in accordance with the following

information excerpted from a National Consensus Standard

as referenced by Federal Government Agencies.

Recommended inspection intervals may vary from crane to

crane and may vary based on environmental conditions,

frequency of lifts, and exposure to shock loads. The

inspection time intervals may also be predetermined by state

and local regulatory agencies.

NOTE: Wire rope may be purchased through Manitowoc

Crane Care.

Any deterioration observed in the wire rope should be noted

in the equipment inspection log and an assessment

concerning wire rope replacement should be made by a

qualified person.

Keeping Records

A signed and dated report of the wire rope’s condition at

each periodic inspection must be kept on file at all times. The

report must cover all inspection points listed in this section.

The information in the records can then be used to establish

data which can be used to determine when a wire rope

should be replaced.

It is recommended that the wire rope inspection program

include reports on the examination of wire rope removed

from service. This information can be used to establish a

relationship between visual inspection and the rope’s actual

internal condition at the time of removal from service.

Frequent Inspection

A frequent daily visual inspection is recommended for all

running ropes in service. This inspection should be made on

all wire rope which can be expected to be in use during the

day’s operation. This inspection should be used to monitor

progressive degradation and to discover severe damages

necessitating wire rope replacement such as:

• Distortion, kinking, crushing, un-stranding, bird caging,

reduction of diameter, etc.

• General corrosion.

• Broken or cut strands.

• Number, distribution and type of broken wires.

• Evidence of core failure.

• End fitting wear/abrasion.

Pay particular attention to areas of the rope where wear and

other damage is likely to occur:

- Pick-up Points: Sections of wire rope that are

repeatedly stressed during each lift, such as those

sections in contact with sheaves.

- End Attachments: The point where a fitting is

attached to the wire rope or the point where the wire

rope is attached to the drum.

- Abuse Points: The point where the wire rope is

subjected to abnormal scuffing and scraping.

Loading...

Loading...