866.4.Maxtec www.maxtec.com12

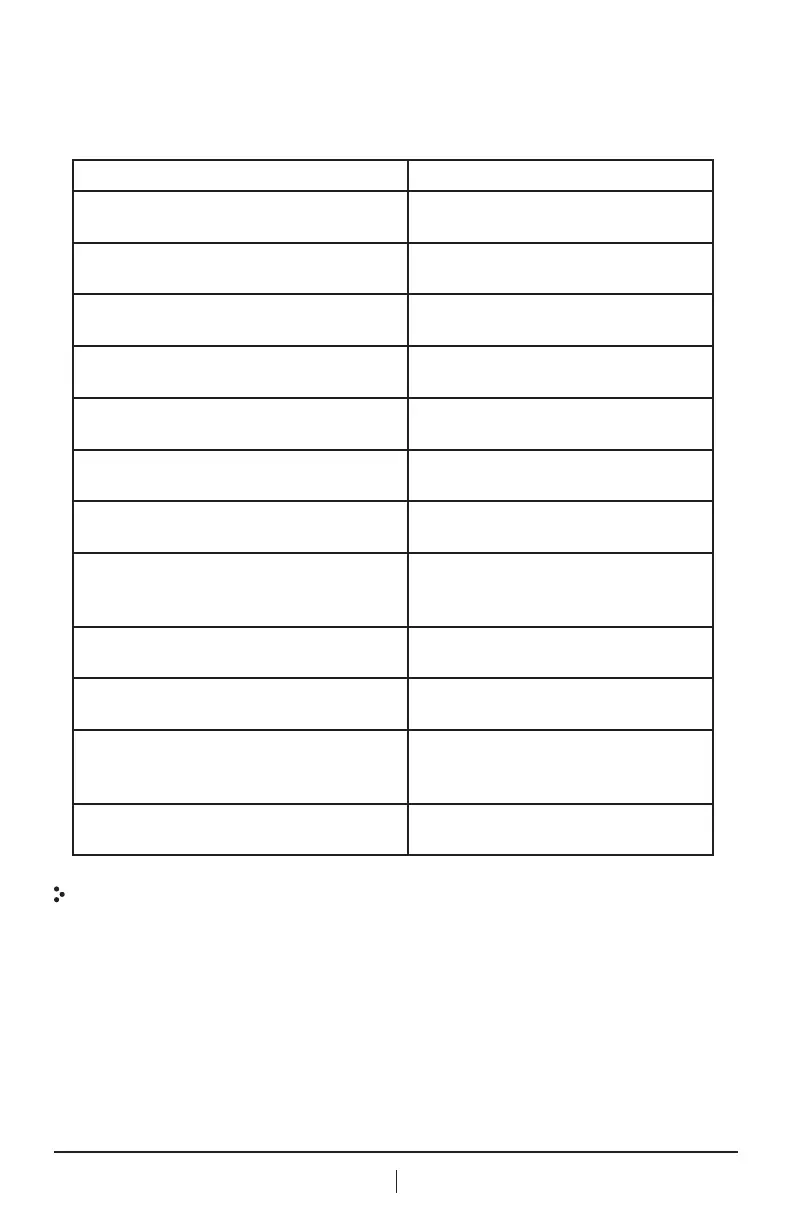

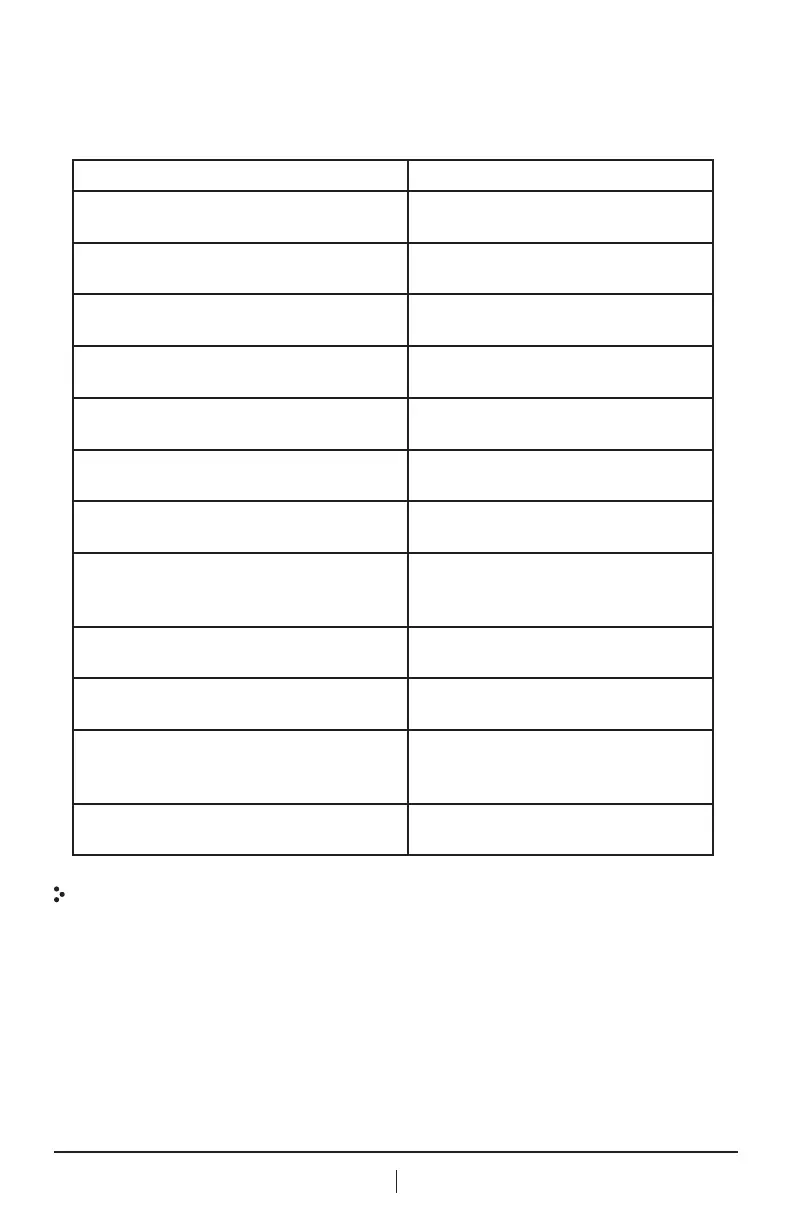

3.1 Blender Safety Check

NOTE: Before proceeding, ensure that the high alarm set point control is OFF [display

reads (--)] and that the low alarm set point control is below 20%.

PROCEDURE MAXBlend2 RESPONSE

1. Adjust the oxygen concentration such

that the display reads 60% O

2

±3%.

No response.

2. Disconnect the 50 PSIG AIR source

from the MAXBlend2.

Audible alarm sounds. Display reads

100%

+/-3%.

3. Reconnect 50 PSIG AIR source to the

MAXBlend2.

Audible Alarm stops. Verify that

display panel reads 60% ±5%.

4. Disconnect 50 PSIG OXYGEN source

from the MAXBlend2.

Audible alarm sounds. Display reads

20.9% +/-3%.

5. Reconnect 50 PSIG OXYGEN to the

MAXBlend2.

Audible alarm stops. Verify that

display panel reads 60% ±5%.

6. Adjust both air and oxygen inlet

regulators to 0 PSIG.

No response.

7. Remove air inlet hose at regulator and

insert end into beaker of water.

No response.

8. Slowly raise pressure of oxygen

regulator to 50 PSIG and back to 0 PSIG

while observing air hose end in beaker.

No bubbles should be observed.

Audible alarm sounds.

9. Dry and reattach air inlet hose to regulator. No response.

10. Remove oxygen inlet hose at regulator,

and insert end into beaker of water.

No response.

11. Slowly raise pressure of air regulator

to 50 PSIG and back to 0 PSIG while

observing oxygen hose end in beaker.

No bubbles should be observed.

Audible alarm sounds.

12. Dry and reattach oxygen inlet hose to

regulator.

No response.

4.0 TROUBLESHOOTING

4.1 Problem Troubleshooting

Problem: Oxygen concentration discrepancy between oxygen concentration

selection knob and actual reading on display.

Potential Causes and Solutions:

»

Monitor out of calibration. Calibrate. Refer to section 2.8, Calibration Procedure.

»

Sensor exhausted. Replace sensor. Refer to section 6.2.

»

Gas supply contaminated. Contact Maxtec for repair of the MAXBlend2.

»

MAXBlend2 blender out of calibration. Contact Maxtec for repair.

Loading...

Loading...