866.4.Maxtec www.maxtec.com 23

0

5

10

15

20

25

0 20 40 60 80 100 120

PressureDrop(PSIG)

FlowRate(LPM)

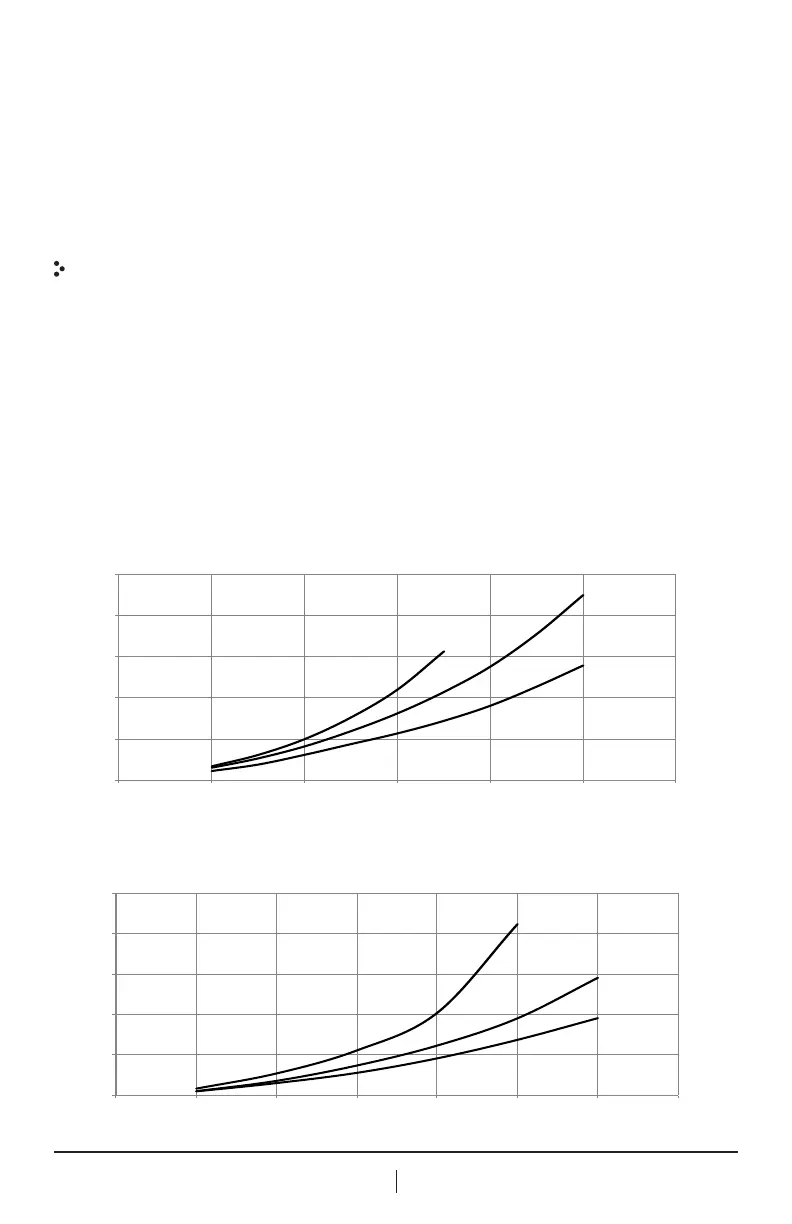

FlowRate-vs-PressureDrop

(ForHighFlowBlender)

Flow Rate -vs- Pressure Drop

(For High Flow Blender)

Pressure drop (PSIG)Pressure drop (PSIG)

Flow Rate (LPM)

Flow Rate (LPM)

If the MAXBlend2 is set to deliver 21% and the OXYGEN source pressure

is reduced enough to produce a 20 PSI (1.3 BAR) differential, the unit may

not alarm because it will continue to deliver 21% concentration according to

the setting. If the setting is moved slightly from 21%, the pressure differential

alarm will sound. Similarly, if the MAXBlend2 is set to deliver 100% and the

AIR source pressure is reduced or lost, the unit may not alarm because it will

continue to deliver 100% concentration.

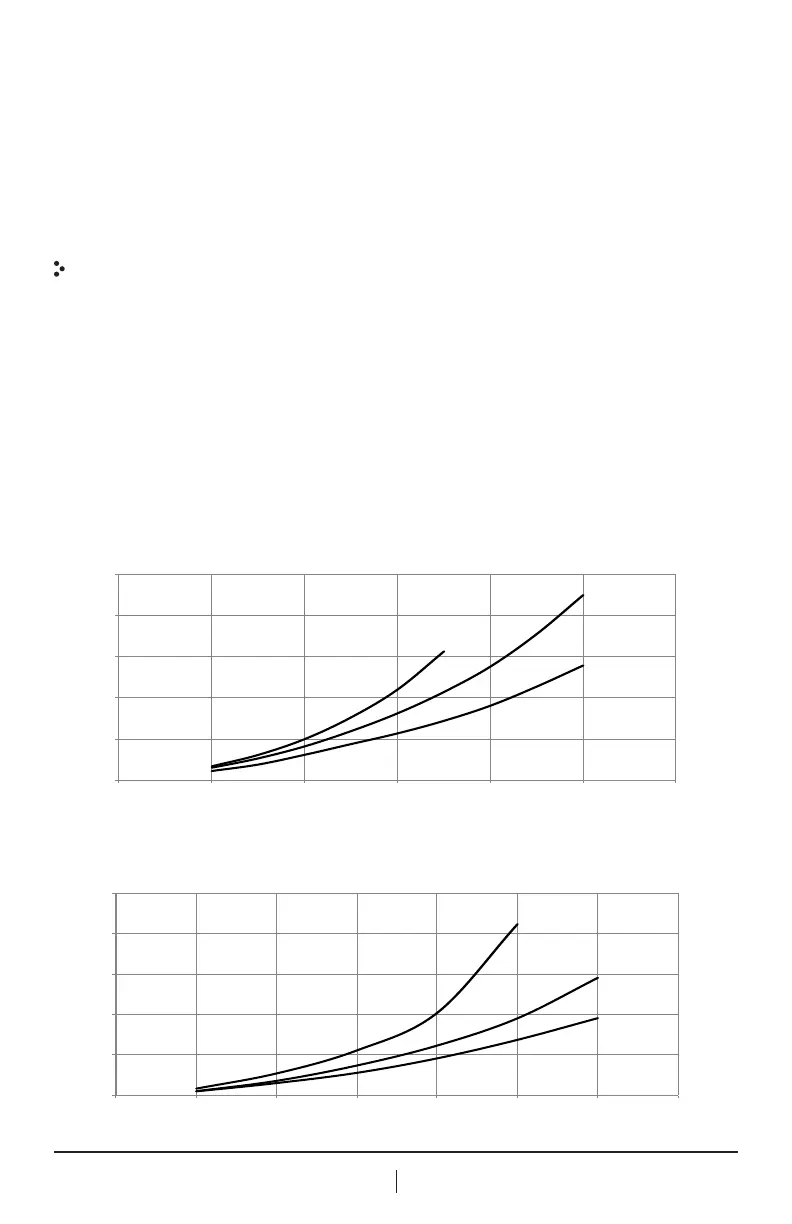

12.0 FLOW CHARACTERISTICS

The outlet pressure of the MAXBlend2 decreases as the total flow rate

increase. The total flow rate is the measurement of the total flow from all

outlet ports. The charts below indicate the pressure drop that occurs for both

low flow and high flow models at 3 inlet pressure settings; 30 PSIG (2.07

BAR), 50 PSIG (3.45 BAR), and 75 PSIG (5.17 BAR).

The fixed acrylic flow meter on the left side of the MaxBlend2 has been

pressure compensated to accommodate for the pressure loss through the

blender at each flow rate, using an inlet pressure of 50 PSIG."

0

5

10

15

20

25

0 5 10 15 20 25 30 35

PressureDrop(PSIG)

FlowRate(LPM)

FlowRate-vs-PressureDrop

(ForLowFlowBlender)

Flow Rate -vs- Pressure Drop

(For Low Flow Blender)

50 psig

50 psig

75 psig

75 psig

30 psig

30 psig

Loading...

Loading...