IM 781-2 Page 27

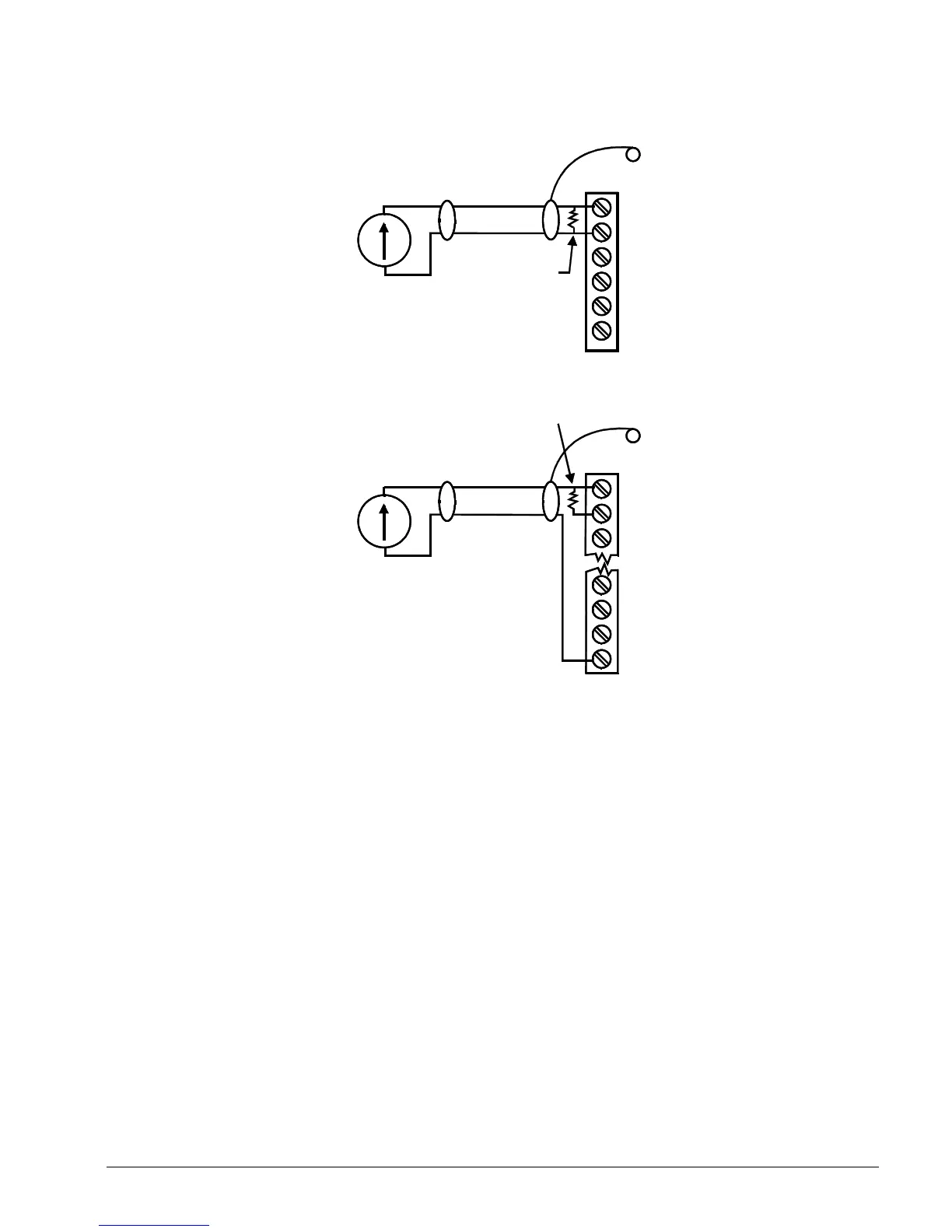

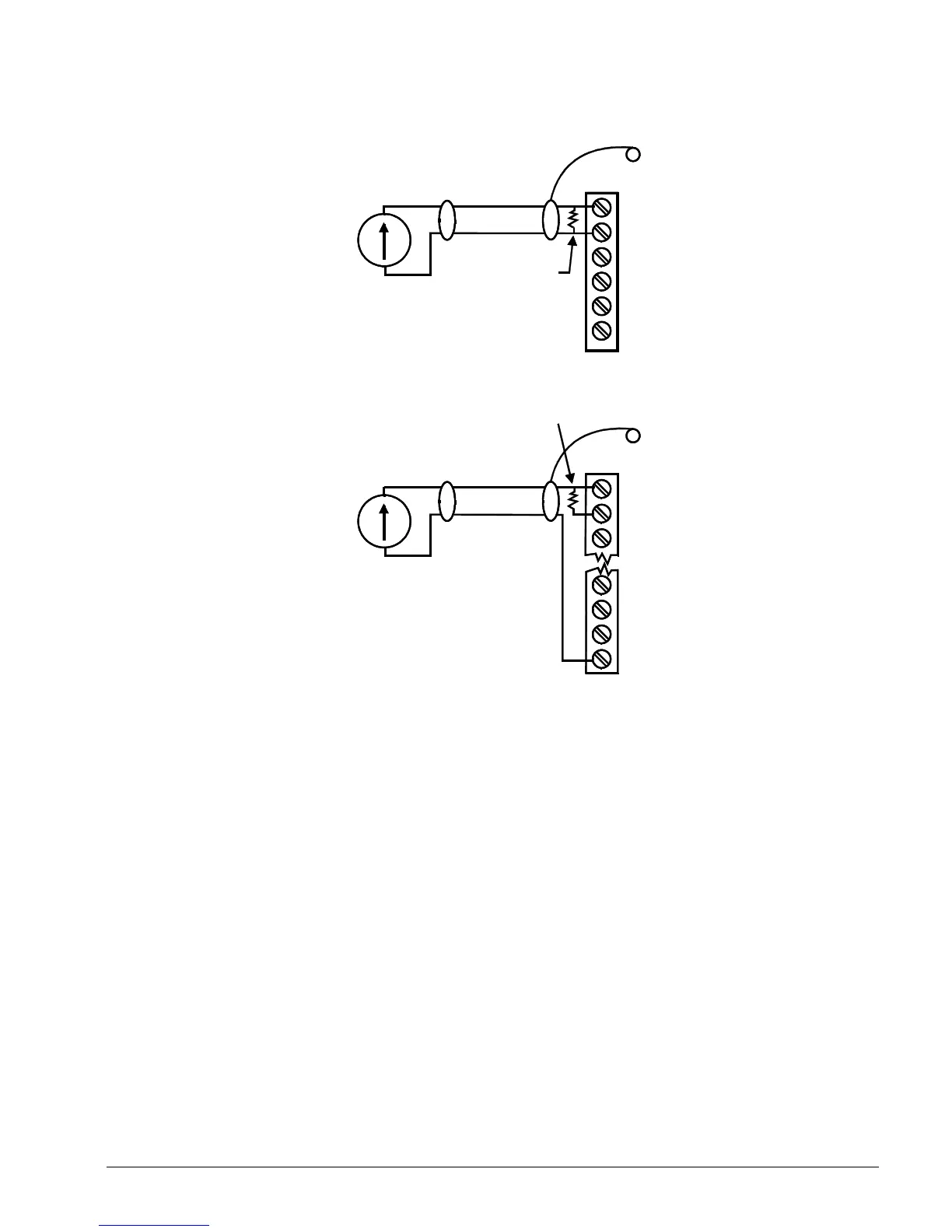

Figure 22. Analog Input 4 to 20 mA Wiring

UI1

G

UI2

Shield

Stud in

enclosur

200' max

Shielded,

Cable

Range: 0-20 mA

4-20 mA

Self-powered

sensor

+

-

i

499 Ohm

(supplied with

UI1

G

UI2

Shield

Stud in

enclosur

200' max

Shielded,

Cable

Range: 0-20 mA

Controller-powered

sensor

+

-

i

499 Ohm

(supplied with

AO3

AO2

AO1

AV+

1. Flow Rate Sensor (UI 7)

A water flow rate sensor is used by the CSM in decoupled chiller sequencing control (primary/secondary systems) to

determine when the system capacity should be decreased by one stage. See Figure 7 through Figure 10 for the location of

the flow rate sensor mounted in the decoupler line. The flow rate sensor can also be mounted in the common supply water

line (after the decoupler line and before the first cooling load branch line). In this case, the CSM calculates the decoupler

line flow by subtracting the primary flow from the measured common supply water line reading.

Note that since flow is only measured in one direction, a uni-directional flow meter is sufficient. If the flow meter is

mounted in the decoupler line it must be sized to measure up to 150% of the evaporator flow rate of the largest chiller. If

the flow meter is mounted in the common supply line it must be sized to measure the total flow capacity of the cooling load

pumps.

When the flow rate from supply to return in the decoupler line is greater than the flow rate of the next chiller to be staged

off by more than the adjustable differential, the system capacity may be reduced by one stage.

2. Chilled Water Loop Differential Pressure Transducer (UI 8)

The chilled water loop differential pressure transducer is used when chilled water loop bypass valve control, sequencing

pump control, or variable speed pump control is required. See Figure 8, Figure 10, and Figure 11. A quality differential

pressure sensor should be selected since water hammer can occur within the loop.

When loop bypass valve control is used, the chilled water loop differential pressure transducer allows the CSM to modulate

a bypass valve as required to maintain an adjustable differential pressure setpoint using a PI (proportional-integral) control

loop.

Loading...

Loading...