Mechanical system

13

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

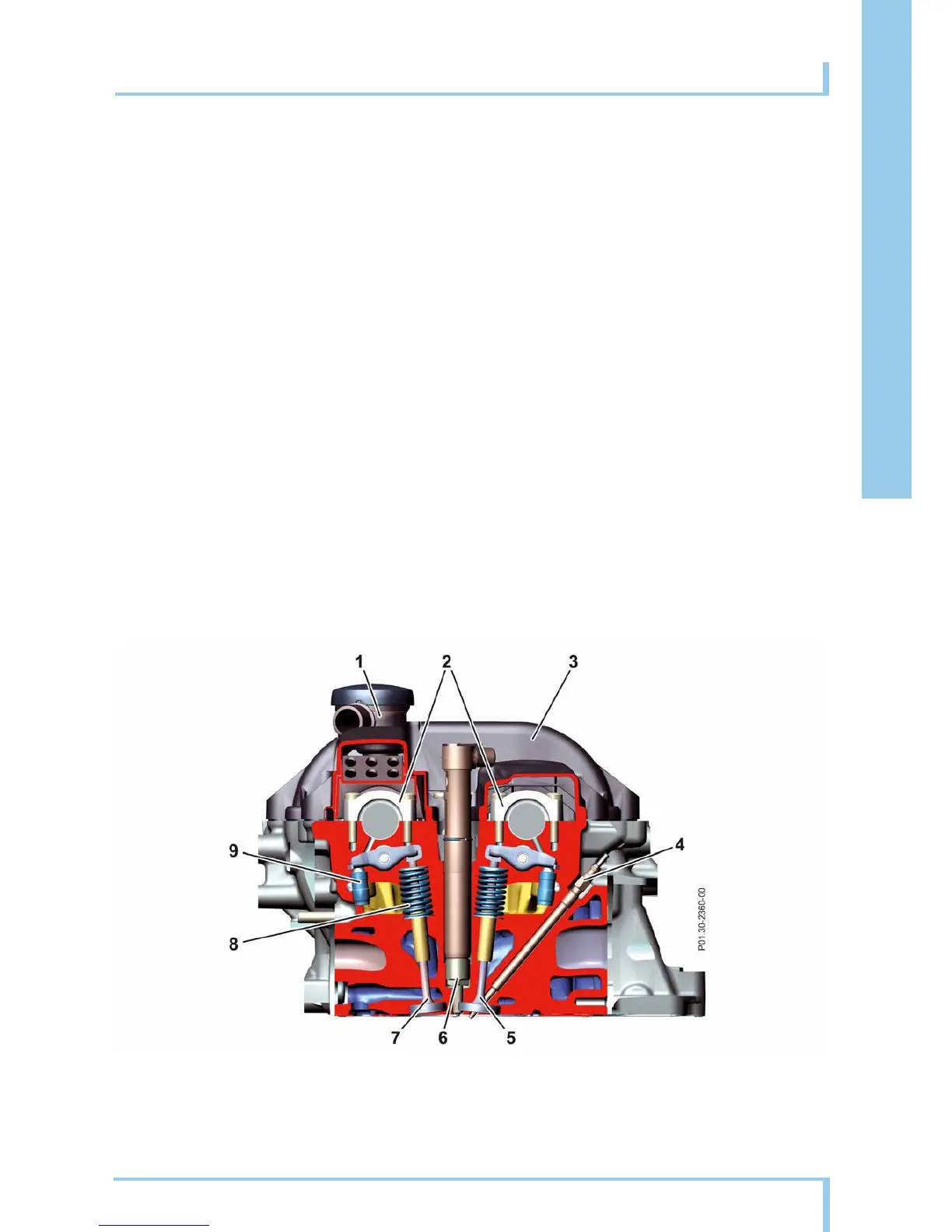

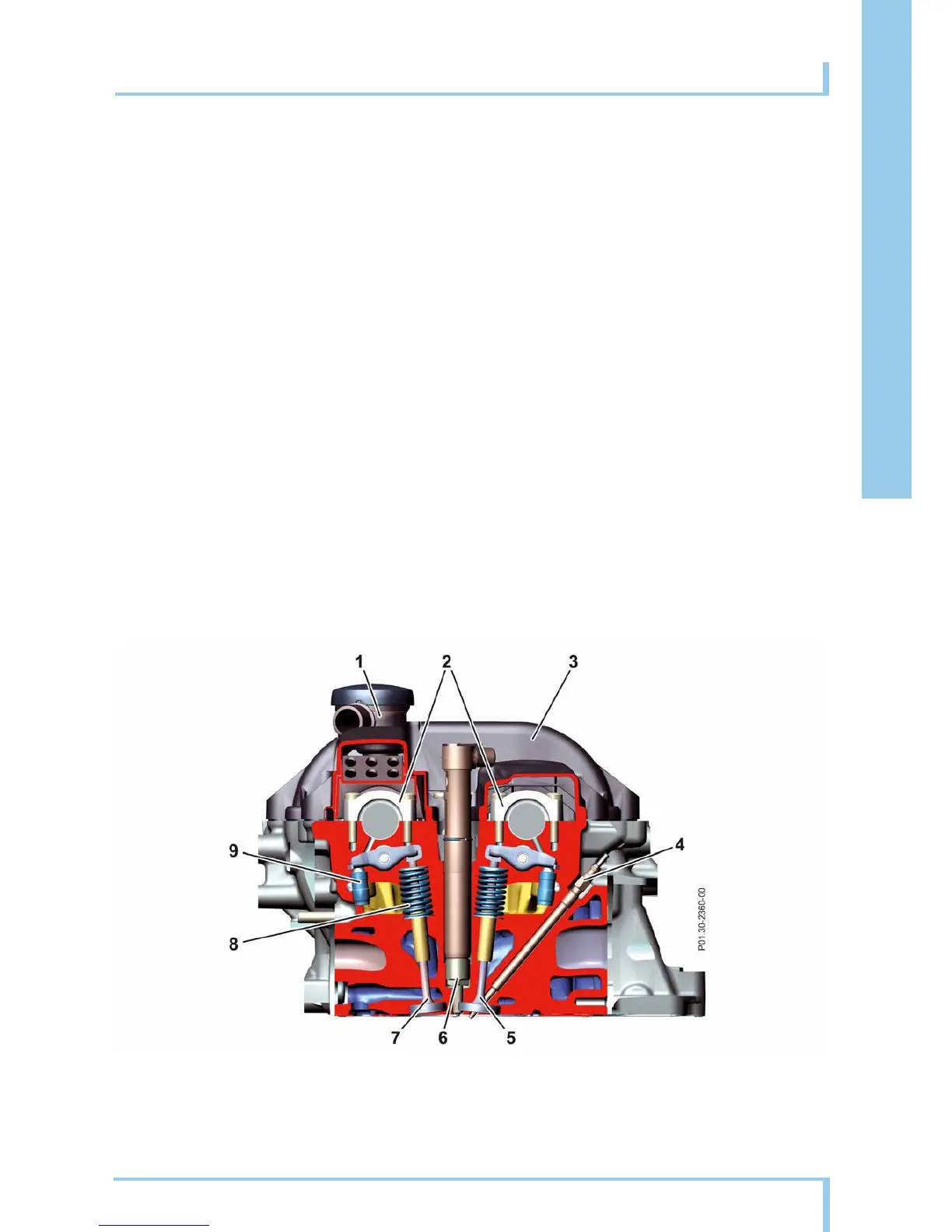

Cylinder head

General

The cylinder head is made of high-strength aluminum.

It is equipped with two camshafts and four valves per

cylinder. The cylinder head cover is made of plastic

with integrated ventilation. The cylinder head is char-

acterized by the following new features:

• Maximum ignition pressure of 200 bar (previously

160

bar)

• Tangential and spiral intake ports

• Bore for piezo injector of 19 mm diameter

The upper duct of the two-piece water jacket supplies

the cylinder

head with coolant. The advantages of the

two-piece water jacket include:

• Greater structural rigidity

• Better heat dissipation

• Improved thermal management

The improved thermal management system is particu-

larly beneficial in those areas which are exposed to

very

high temperatures. The high ignition pressure of

200 bar is only made possible by targeted cooling of

the individual components. The increased pressure

potential and optimized injection quantity are respon-

sible for the high engine torque of 500 Nm and the

en

gine output of 150 kW.

Cross-section of cylinder head

1 Ventilation

2 Main bearing bridge

3 Cylinder head cover

4Glow plug

5 Exhaust valve

6 Piezo injector

7 Intake valve

8 Valve spring

9 Valve clearance compensation

Loading...

Loading...