Engine lubrication and oil circuit

38

Cooling and lubrication

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

Lubricating system

The engine lubrication system minimizes the mechan-

ical friction and thus the wear

on moving parts. In

addition, the oil pads between the bearings and

running surfaces reduce shocks and vibrations. A

pressure differential valve is installed in parallel to the

oil-water heat exchanger to ensure that the engine is

lubricated at all times. This allows the oil to be routed

around the oil-water heat exchanger.

Oil circuit

All of the moving components of the engine are lubri-

cated and / or cooled with engine oil via the oil circuit

of the engine.

The oil circuit of the engine is supplied with engine oil

via the oil pump. In addition, the vacuum pump is

driven and sup

plied with engine oil via the oil pump.

The following components in the crankcase are

supplied with engine oil via the main oil duct:

• Crankshaft bearings

• Connecting rod bearings

• Intermediate gears

• Oil spray nozzles

The two turbochargers are supplied with engine oil via

a bypass

of the main oil duct.

The oil supply for the cylinder

head branches off from

the main oil duct. The following lubrication points in

the cylinder head are supplied with engine oil:

• Cam chain tensioner

•Intake camshaft

•Exhaust camshaft

• Hydraulic valve clearance compensator

The engine oil is returned to the oil pan via return

ducts.

i Note

The CDI control unit reads in the oil level check

switch to monitor the oil level and the oil temper-

ature sensor to monitor the oil temperature.

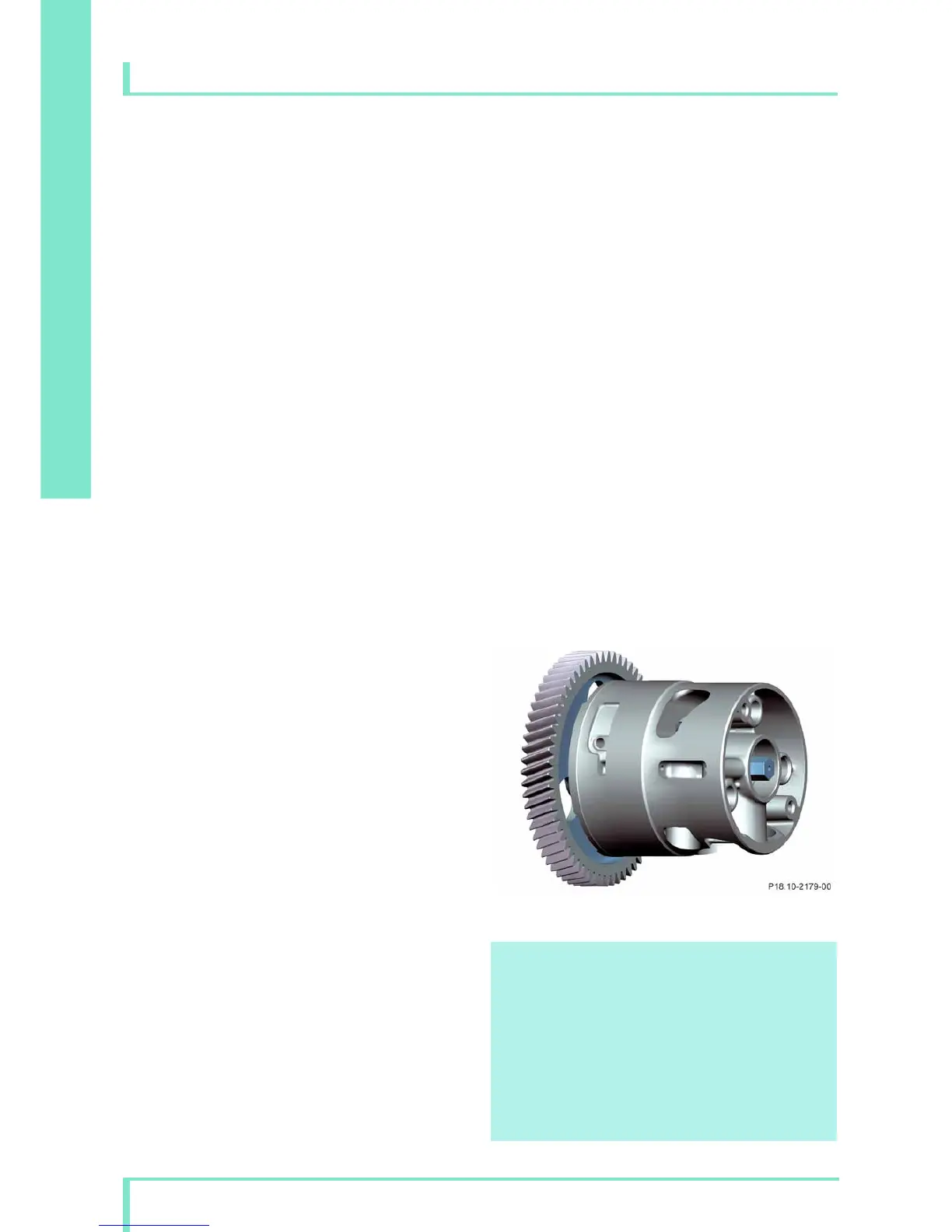

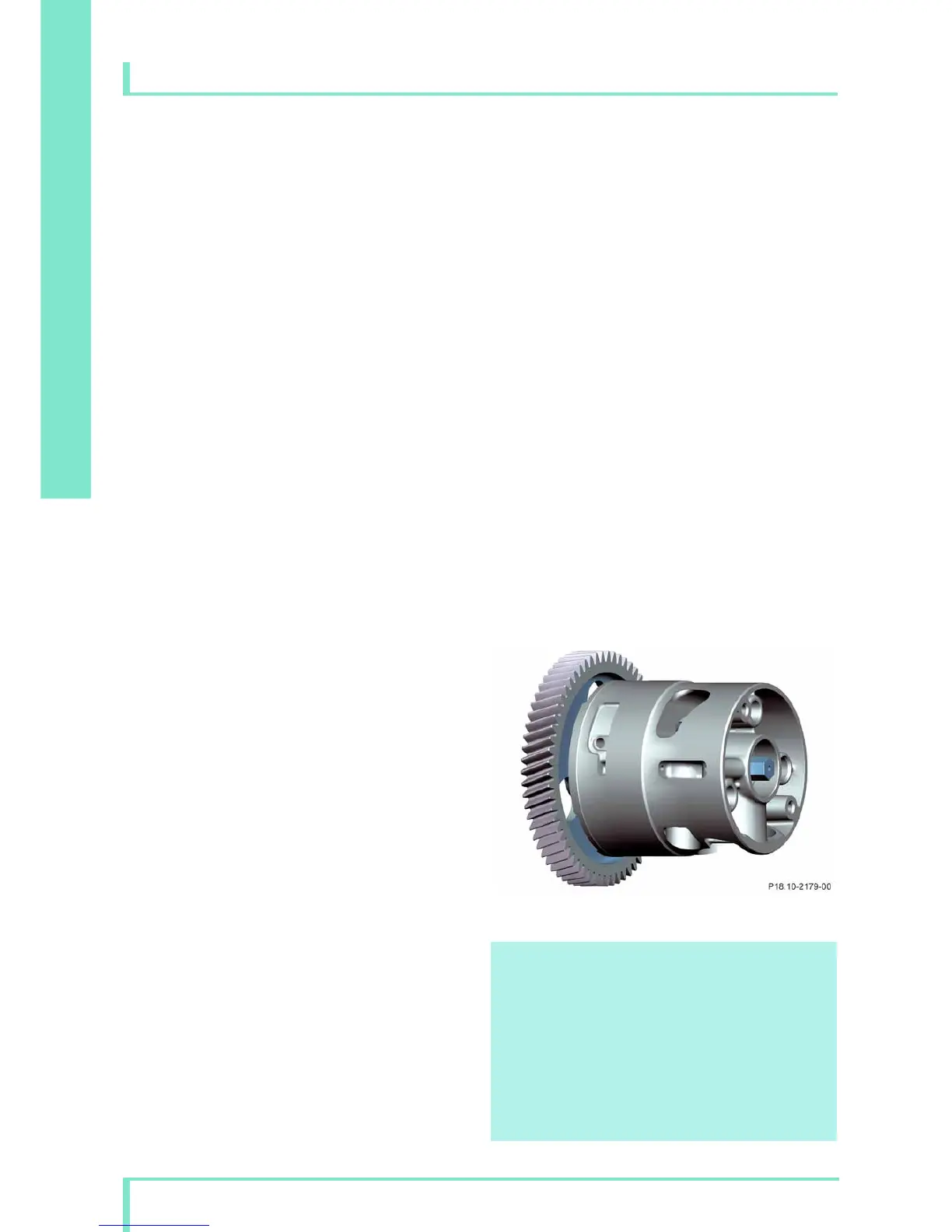

Oil pump

Loading...

Loading...