Mechanical system

15

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

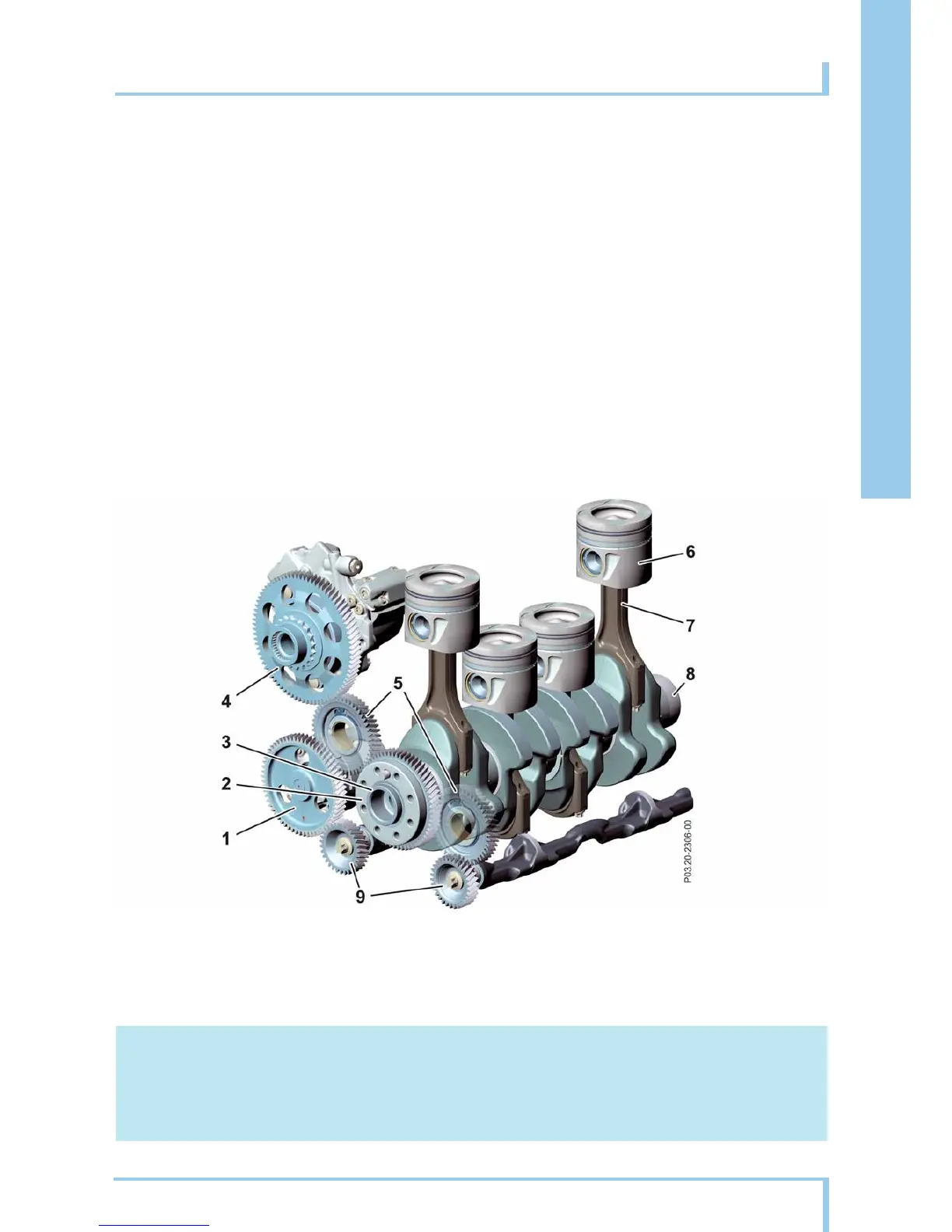

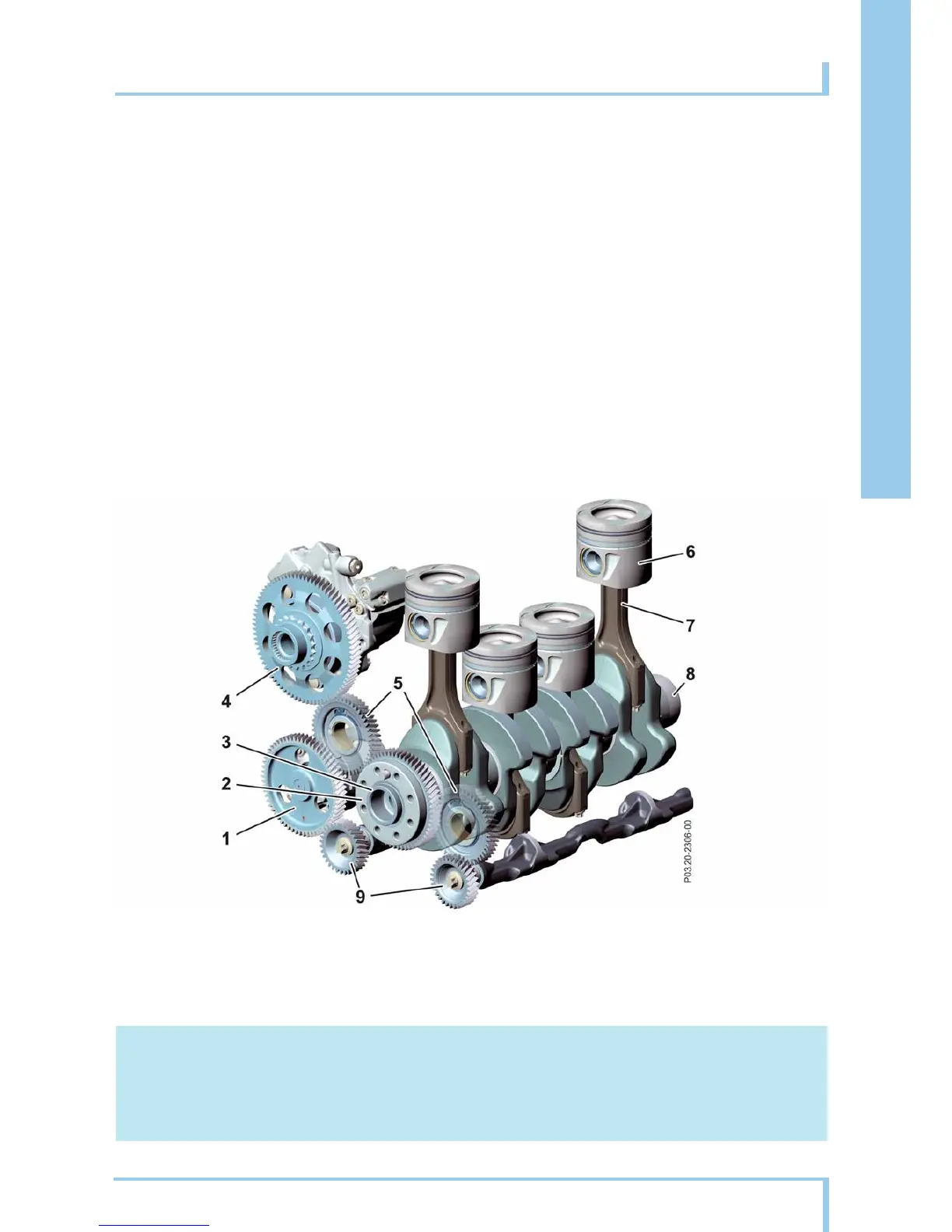

Crankshaft assembly

Crankshaft

The forged crankshaft with eight counterweights is

supported by five bearings for effective vibration

damping. The radiuses of the crank pins are rolled to

give them high strength. In addition, the connection

between the drive gear and crankshaft is friction

welded.

The vibration damper is fixed to the crankshaft with a

fourfold threaded connection.

Connecting rods

The weight-optimized connecting rods are made of

forged steel and are cracked at the level of the bearing

shells.

Balance shafts

Two Lanchester balance shafts are integrated in the

main bearing bridge and mounted on three roller bear-

ings. They are driven in opposite directions by the gear

drive to counteract the inertia forces of the second

order which are generated. This ensures smooth

engine running.

i Note

The aluminum pistons run in friction-optimized cast-iron cylinder barrels. On this engine, they are all manu-

factured uniformly. There is therefore no differentiation between A, B or X sizes on this engine.

Crank assembly with gear drive

1 Oil and vacuum pump drive gear

2 Crankshaft gear

3Crankshaft

4 High-pressure pump drive gear

5 Intermediate gears

(tensioning gears)

6Piston

7 Connecting rod

8Vibration damper

9 Lanchester drive gears

Loading...

Loading...