Exhaust system

34

Combustion

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

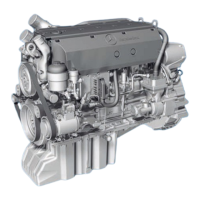

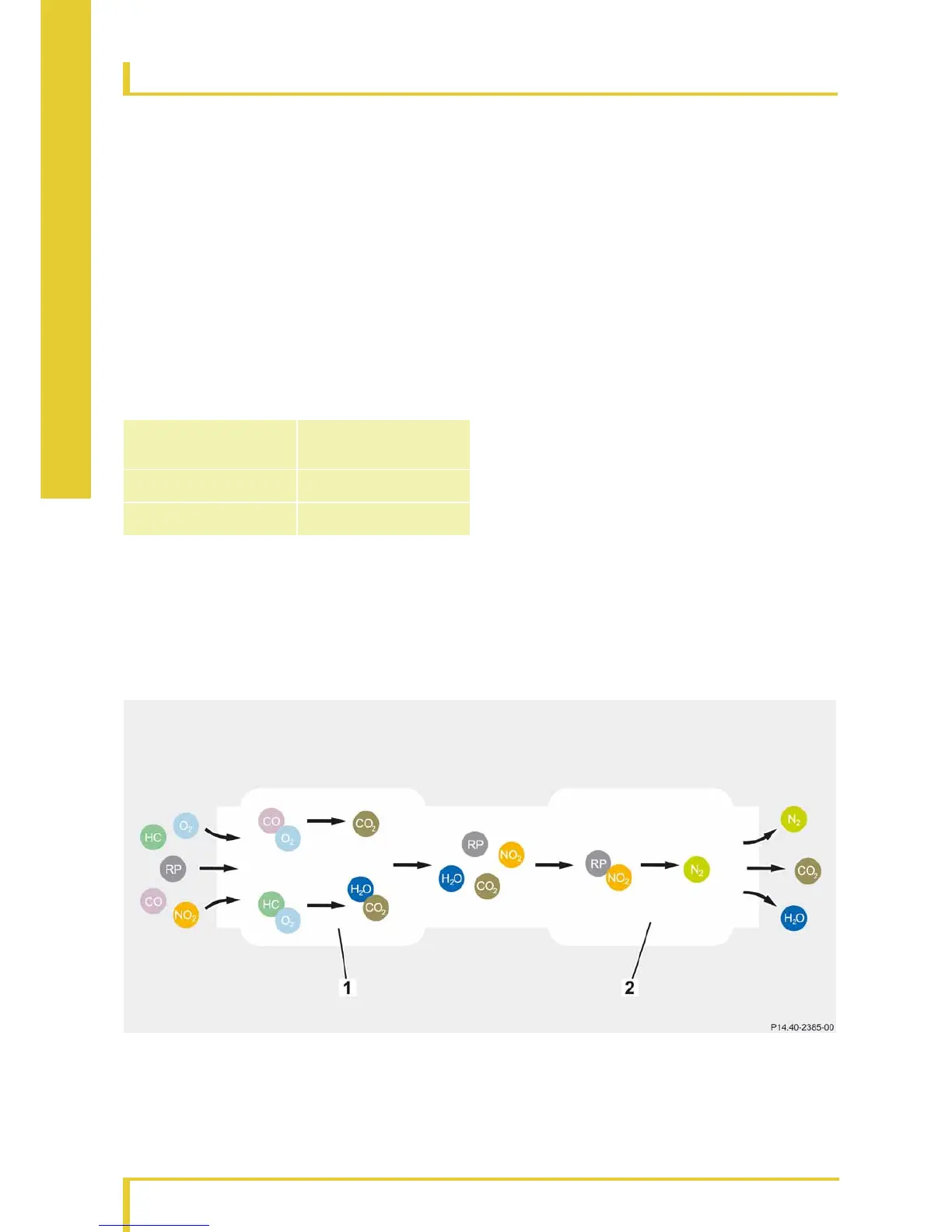

Oxidation catalytic converter

The oxidation catalytic converter is part of the exhaust

system and is located in the exhaust tract down-

stream of the turbocharger.

The ceramic body is made of highly temperature resis-

tant magnesium-aluminum-alumosilicate and has

several thousand sm

all passages running all the way

though it. The ceramic monolith reacts extremely

sensitively to physical stress and is fixed in place

inside a stainless steel housing.

Diesel particulate filter (DPF)

The diesel particulate filter (DPF) forms a unit with the

oxidation catalytic converter.

The ceramic DPF is made of silicon carbide and coated

with platinum. The individual channels open

out alter-

nately to the front or to the rear and are separated

from each other

by porous filter walls.

When the unfiltered exhaust gas flows through the

porous

ceramic honeycomb filter, the soot particles

are held back by the porous filter walls. The CDI

control unit measures the load condition of the DPF

via the pressure differential sensor. The exhaust pres-

sure upstream of and downstream of the DPF is

measured for this purpose. Regeneration

of the DPF is

initiated once a defined value is reached. Tempera-

tures of over 600 °C are necessary to burn off the

soo

t. The CDI control unit initiates the following steps

in order to reach these high temperatures:

•Post injection

• Exhaust gas recirculation w

ith intake air throttling

• DPF glow function

The individual pollutant components are oxi-

dized as follows:

Before oxidation After oxidation

2CO + O

2

2CO

2

4HC + 5O

2

2H

2

O + 4CO

2

Schematic illustration of oxidation catalytic converter and DPF

1 Oxidation catalytic converter

2DPF

CO Carbon monoxide

CO

2

Carbon dioxide

O

2

Oxygen

HC Hydrocarbon

H

2

OWater

N

2

Nitrogen

NO

2

Nitrogen oxide

PM Particulate matter

Loading...

Loading...