The owner/operator is not to modify the engine in any manner that would alter

the horsepower or allow emission levels to exceed their predetermined factory

specifications.

Inspection and Maintenance Schedule

BEFORE EACH USE

•

Check engine oil level. Refer to Checking Engine Oil Level.

• Check that the lanyard stop switch stops the engine.

• Inspect the outboard for tightness to the boat transom. If any looseness of

the outboard or mounting fasteners exist, tighten the outboard mounting

fasteners to the specified torque. When looking for signs of looseness,

look for loss of outboard transom bracket material or paint caused by

movement between the outboard mounting fasteners and the outboard

transom brackets. Also look for signs of movement between the outboard

transom brackets and the boat transom (lift plate/setback bracket).

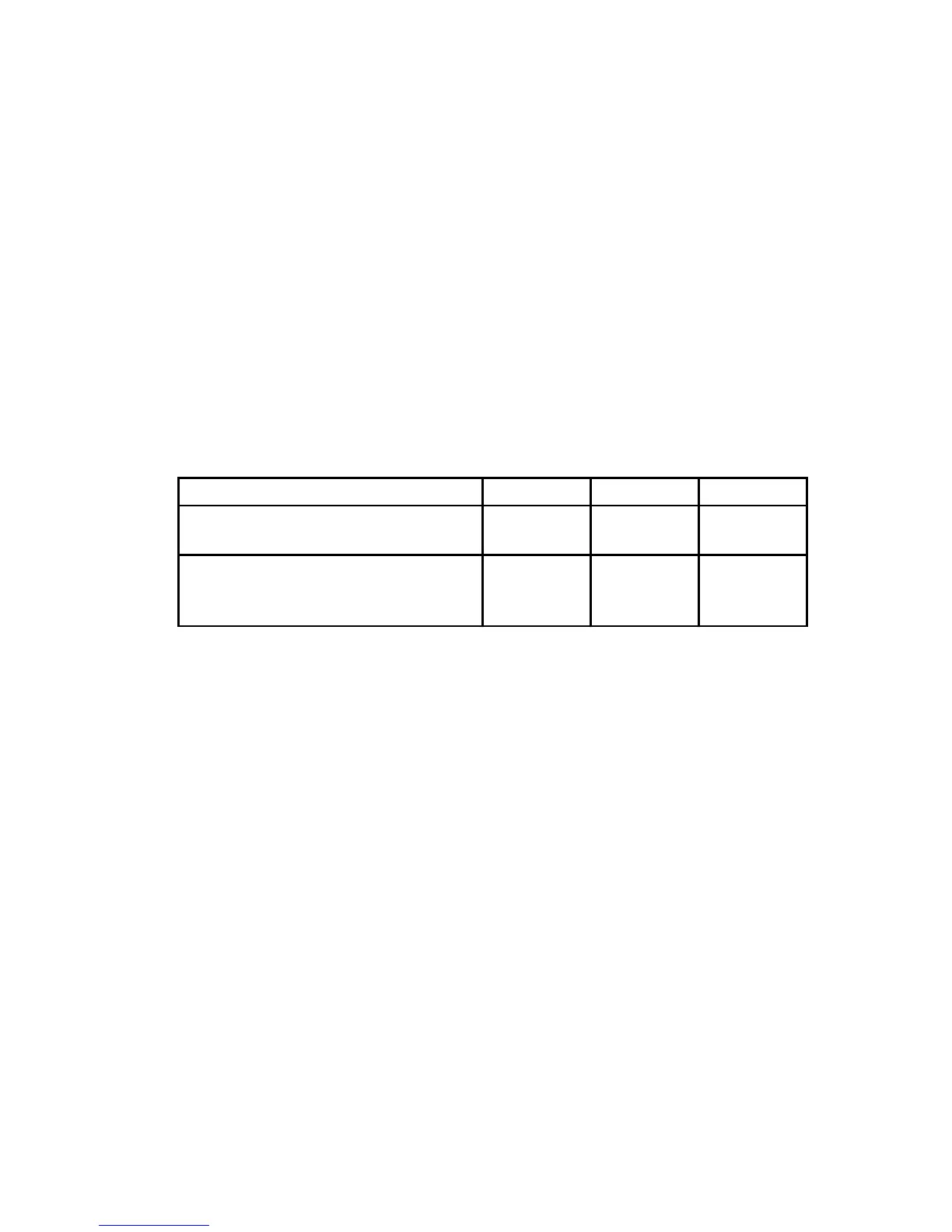

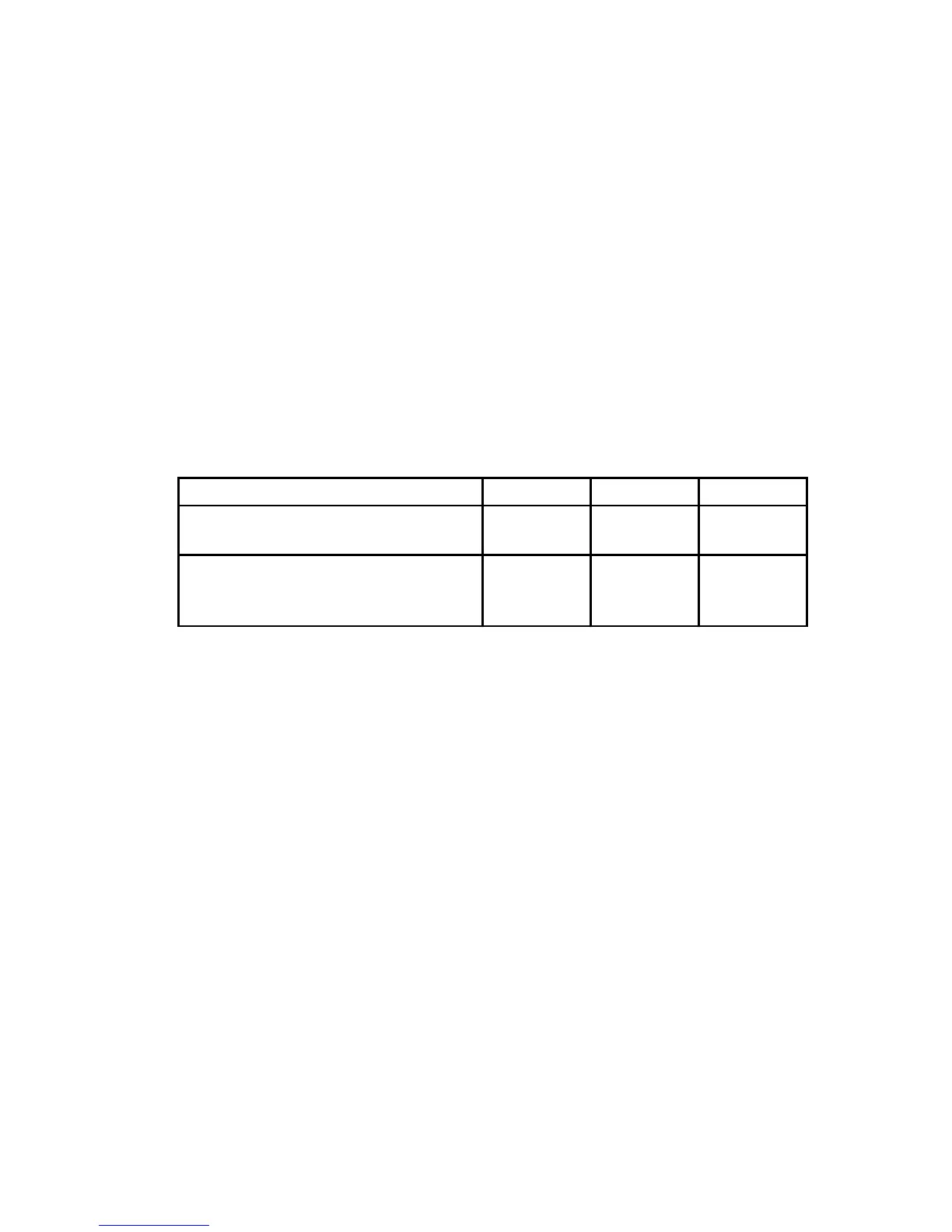

Description

Nm lb‑in. lb‑ft

Outboard mounting locknuts and

bolts ‑ standard boat transom

75 – 55.3

Outboard mounting locknuts and

bolts ‑ metal lift plates and setback

brackets

122 – 90

• Visually inspect the fuel system for deterioration or leaks.

• Check the steering system for binding or loose components.

• Check the propeller blades for damage.

• Inspect the hydraulic steering fittings and hoses for leaks or damage, if

equipped.

• Inspect the hydraulic steering fluid level, if equipped.

AFTER EACH USE

• Flush out the outboard cooling system if operating in salt, polluted, or

muddy water. Refer to Flushing the Cooling System.

• Wash off all salt deposits and flush out the exhaust outlet of the propeller

and gearcase with fresh water if operating in saltwater.

• If operating in saltwater, inspect the powerhead and powerhead

components for salt buildup. Refer to Cleaning Care for the Powerhead

(Saltwater Use).

EVERY 100 HOURS OF USE OR ONCE YEARLY, WHICHEVER

OCCURS FIRST

•

Inspect the exhaust water strainer. Refer to Exhaust Water Strainer

Inspection.

MAINTENANCE

eng 49

Loading...

Loading...