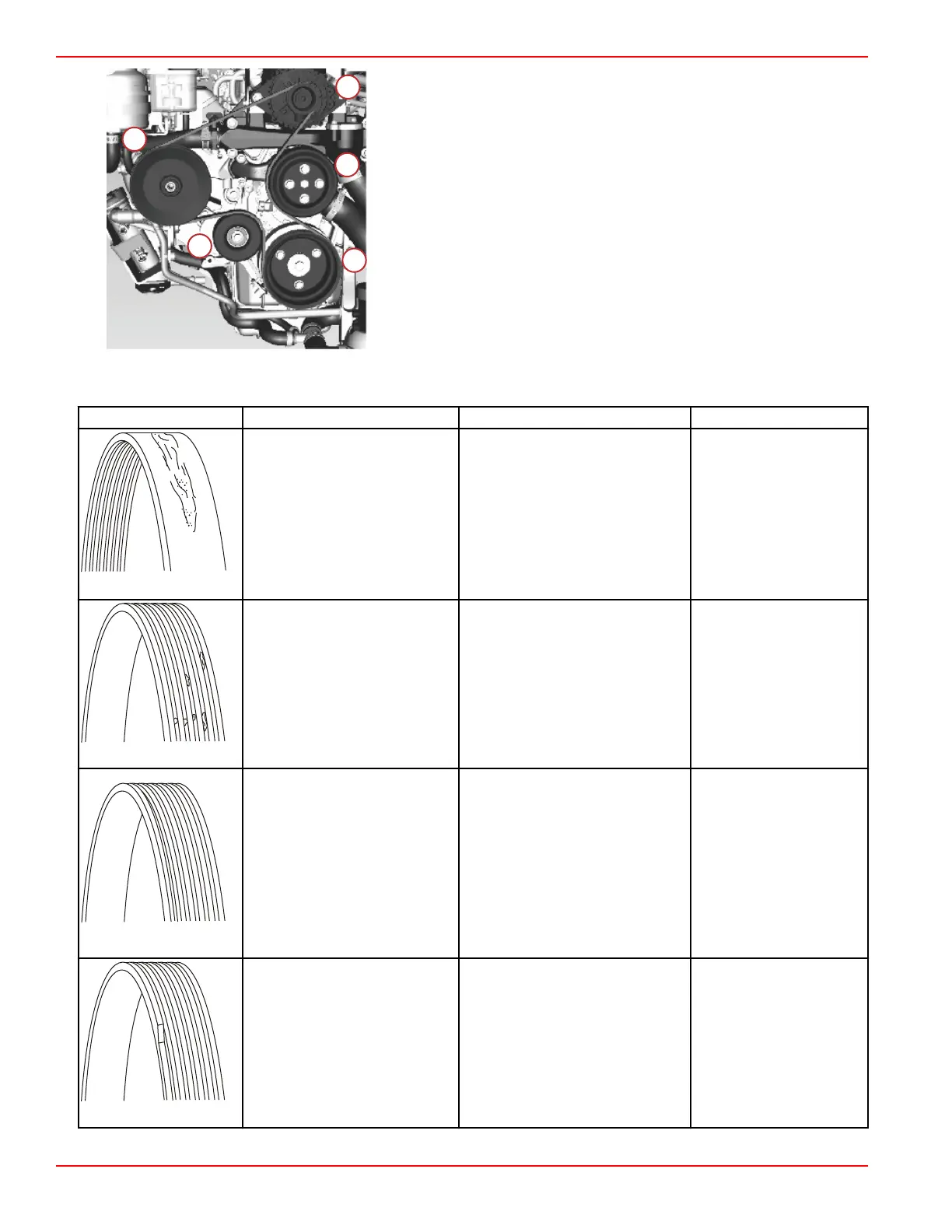

Without a seawater pump

a - Alternator pulley

b - Water circulating pump pulley

c - Crankshaft pulley

d - Belt tensioner

e - Power steering pump pulley

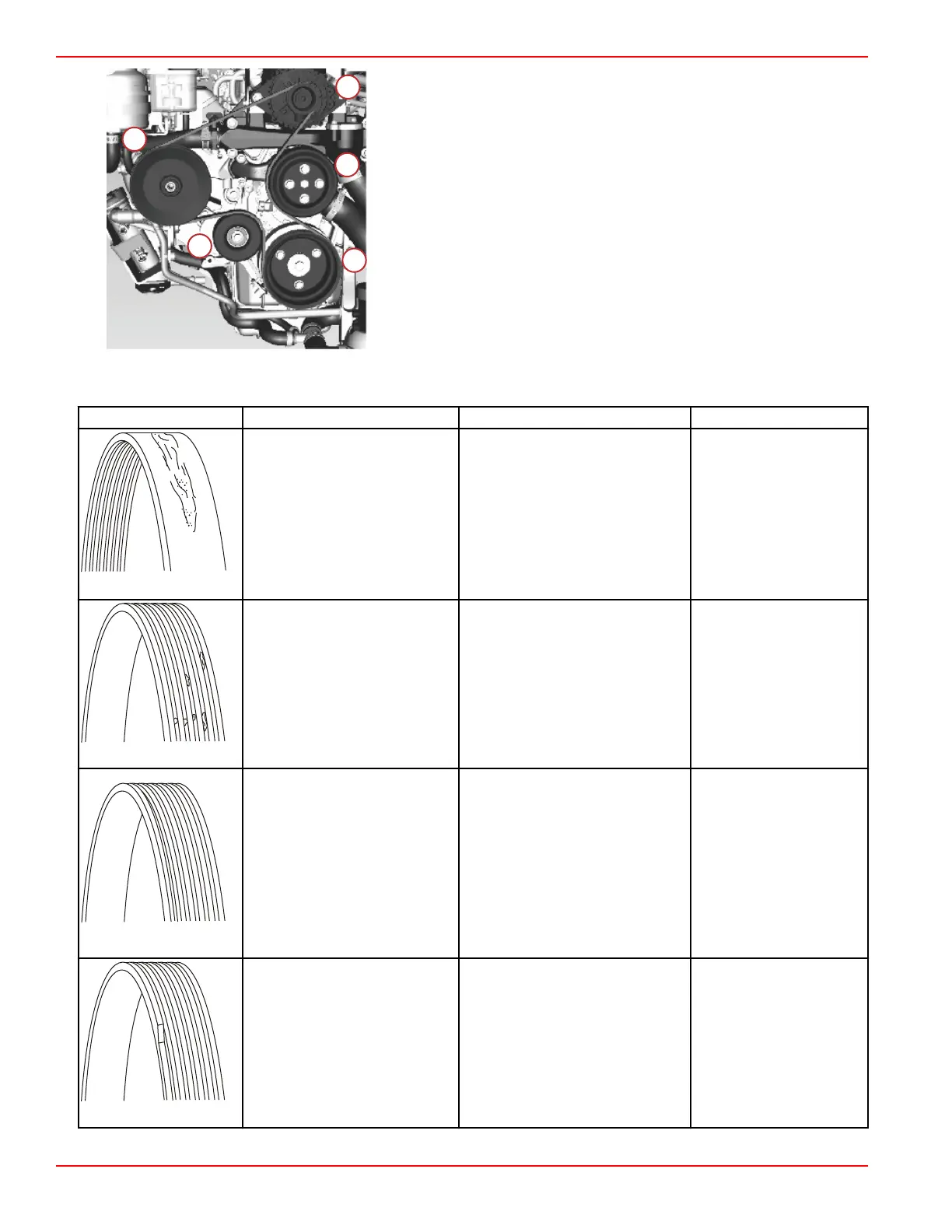

Serpentine Belt Failure Identification

Appearance

Description Cause Solution

Abrasion

Each side of the belt appears

shiny or glazed. Severe

condition: Fabric is exposed.

Belt is in contact with an object.

Can be caused by improper belt

tension or tensioner failure.

Replace the belt and

inspect for contact with an

object. Verify the belt

tensioner is functioning.

Pilling

Belt material is sheared off from

the ribs and builds up in the belt

grooves.

There are a number of causes

including lack of tension,

misalignment, worn pulleys, or a

combination of these factors.

When pilling leads to belt

noise or excess vibration,

the belt should be

replaced.

Improper install

The belt ribs begin separating

from the joined strands. If left

unattended, the cover will often

separate, causing the belt to

unravel.

Improper belt installation is a

common cause of premature

failure. One of the outermost belt

ribs is placed outside the pulley

groove, causing a belt rib to run

without a supporting or aligning

pulley groove.

The belt life has been

severely limited and

should be replaced

immediately. Ensure all

ribs of the replacement

belt fit into the pulley

grooves. Run the engine.

Then, with the engine off

and battery disconnected,

inspect the belt for proper

installation.

Misalignment

Sidewalls of the belt may appear

glazed or the edge‑cord may

become frayed and the ribs are

removed. A noticeable noise

may result. In severe cases, the

belt can jump off the pulley.

Pulley misalignment. Misalignment

forces the belt to kink or twist while

running, causing premature wear.

Replace the belt and verify

the alignment of the pulley.

Section 4 - Maintenance

Page 70 90-8M0128973 eng MAY 2017

Loading...

Loading...