7

TO AVOID DAMAGE TO SENSITIVE

ELECTRONICS, REMOVE THE COV ER

FROM THE ECC CAREFULLY.

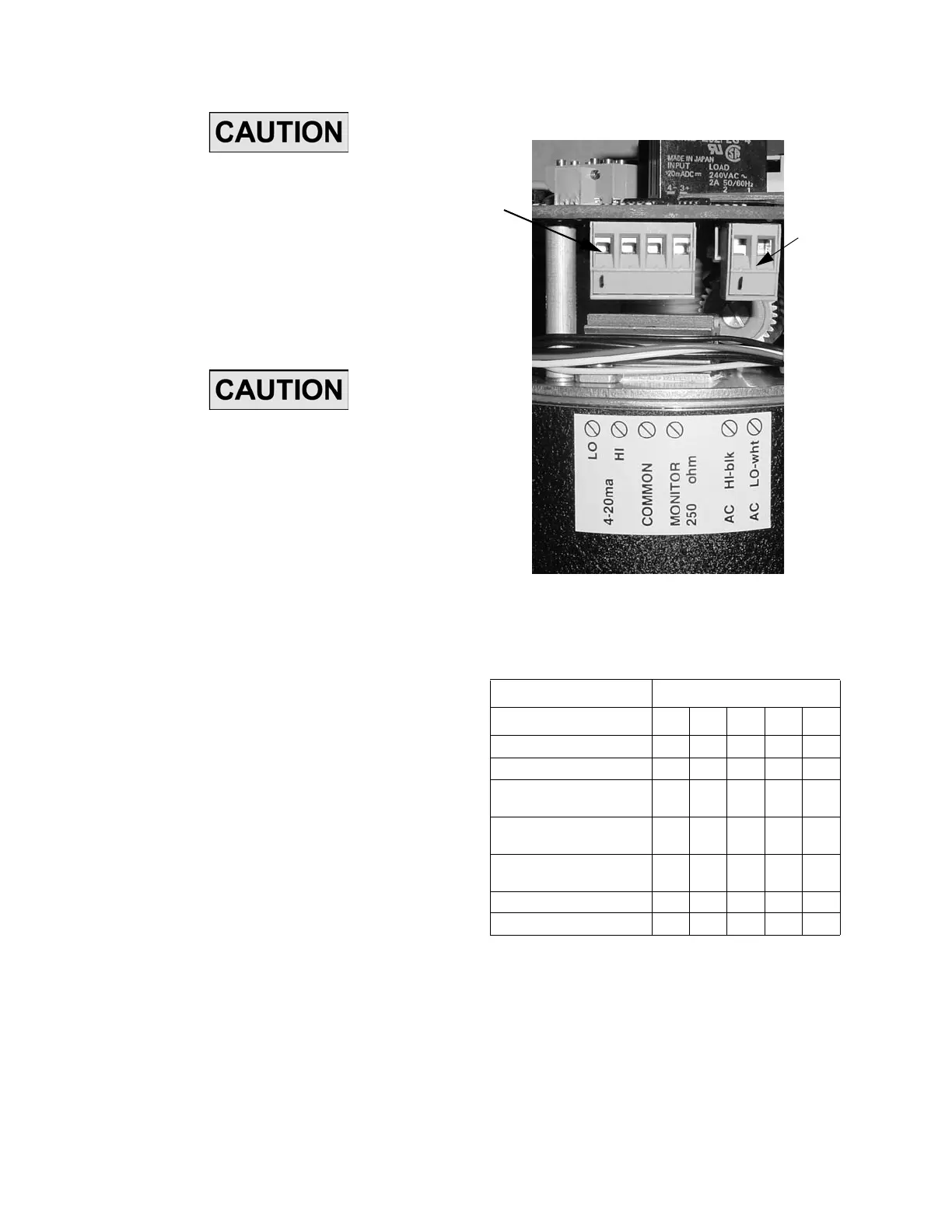

2.6.1 Inst allation of Input/Output Comma nd

Signal Wiring

1. Uns crew the ECC cover by turning it counter-

clockwise (as viewed fro m the top ). Lif t th e

cover straight off and away.

IMPROPER CONNECTION OF THE

COMMAND LIN ES CA N CAU SE DA M-

AGE TO THE ECC. USE ONLY 300

VOLT, 105°C RATED WIRE , MINIMUM

22 AWG, MAXIMUM 14 AWG.

2. Maintain integrity of safety approv als us ing

only 300 volt, 105° C (UL 1213 or equiv.) rated

insulation. Maintain CE immunity ratings, using

shielded cable inside of conduit.

3. Feed fo ur (1 4 to 2 2 A WG) shield ed wir es

through appropriately r ated con duit b ushing

inserted into one of the conduit holes in base of

ECC. Ground shields for four wires to a good

chassis ground at control end.

4. Route wires to ECC keeping electrical interfer-

ence to a minimum. Carefully pull four-position

connector J5 from circuit board. Connect com-

mand signa l wir es to co nnector J5 (Figure 4

and 12 ). Re connect con nector J5 to circuit

board.

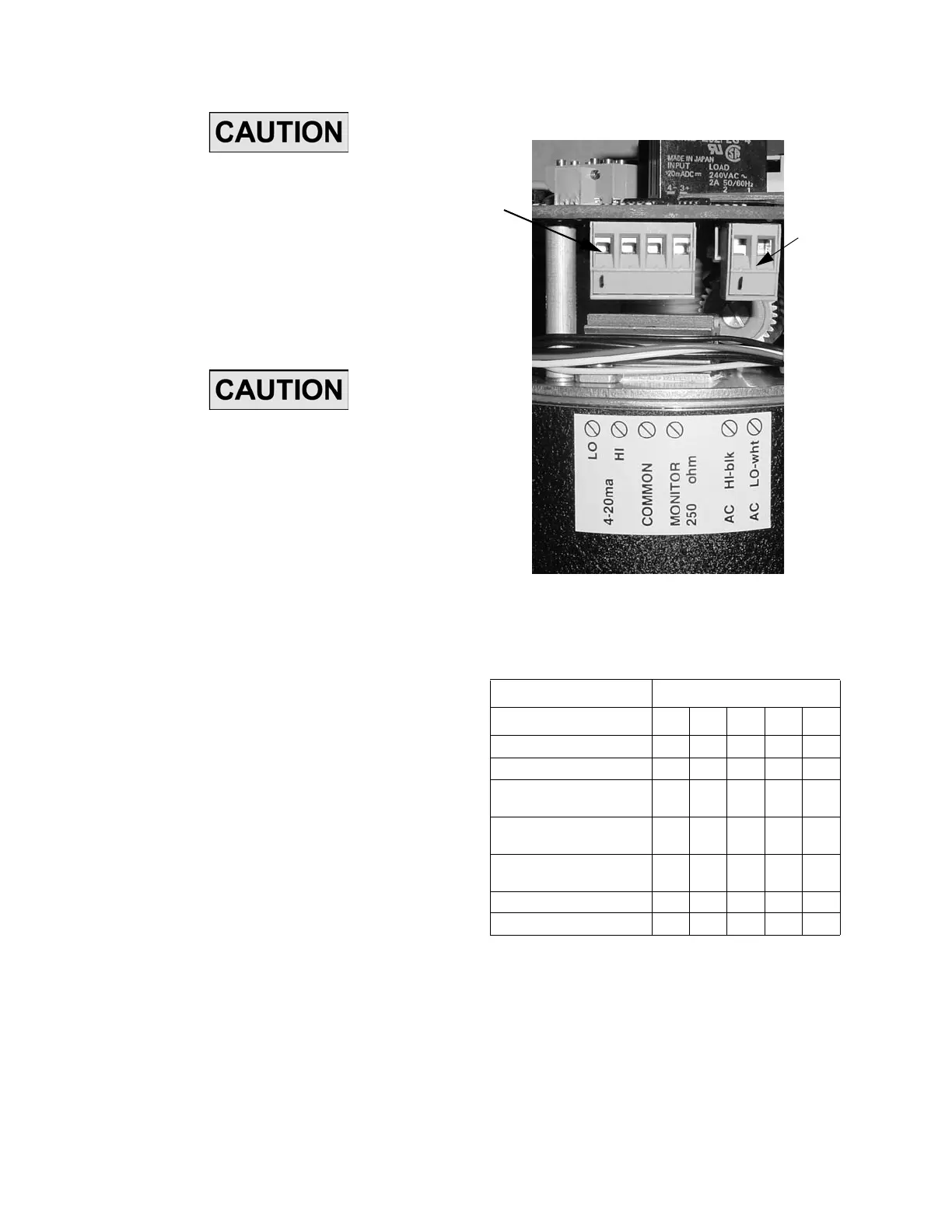

2.6.2 Input Signal

The input signal, used to control the ECC, can be

either 4- 20 mA or (1-5 VDC). A five-position Dip

switch, SW2 (F igure 11, located on the top of th e

circuit board) selects the control signal used by the

operator. The f actory se ts SW2 fo r the model

ordered and should not need changed. Position

1 (Table 10) of SW2 sets the input signal. Position

2 sets the movement of the ECC after unintentional

loss of the control signal. Position 3 and 4 sets the

ECC for use with a pump o r valve a nd should

always be set to 3- OFF and 4 -ON for the pum p

mode. Position 5 is not used.

Figure 4. Circuit Board Connectors J4 and J5

2.6.3 Feedback Output Signal

A position output, proportional to ECC po sition, is

used for remote position indication. A current of 4-

20 m A or a volt age of 1 -5 VDC is a vailable

between MONIT OR (J5- 4) and COMMON ( J5-3).

Feedback zero an d feed back sp an adju stments

(Figure 1 1) ar e p rovided to fine tu ne th e ou tput

(see calibration instructions). DIP switch SW3 (Fig-

Table 10. SW2 DIP Switch Settings

INPUT SWITCH POSITION

12345

Input Signal of 4-20 mA ON

Input Signal of 1-5 VDC OFF

Hold Position on Loss of

Control Signal

ON

Return to Lower Limit on

Loss of Control Signal

OFF

Pump Mode (limits abso-

lute)

OFF ON

Valve Mode (limits floating) ON OFF

Not Used NC

J4

J5

www.motralec.com / service-commercial@motralec.com / 01.39.97.65.10

Loading...

Loading...