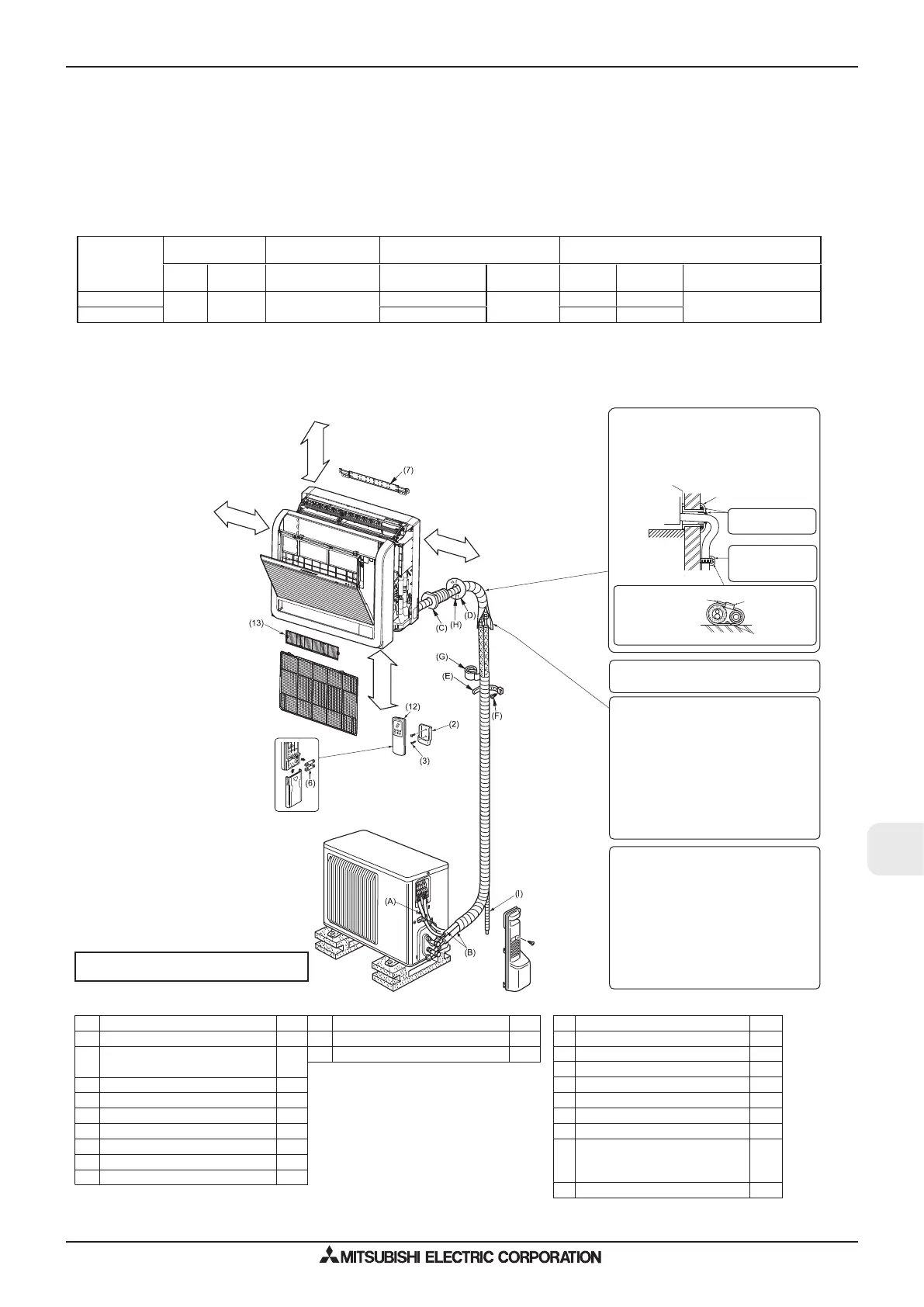

SPECIFICATIONS

*1 Connect to the power switch which has a gap of 3 mm or more when open to

interrupt the source power phase. (When the power switch is shut off, it must

interrupt all phases.)

*2 Use wires in conformity with design 60245 IEC 57.

*3 Never use pipes with thickness less than specified. The pressure resistance

will be insufficient.

*4 Use a copper pipe or a copper-alloy seamless pipe.

*5 Be careful not to crush or bend the pipe during pipe bending.

*6 Refrigerant pipe bending radius must be 100 mm or more.

*7 Insulation material : Heat resisting foam plastic 0.045 specific gravity

*8 Be sure to use the insulation of specified thickness. Excessive thickness may

cause incorrect installation of the indoor unit and insufficient thickness may

cause dew drippage.

Model

Power supply *1 Wire specifications *2

Pipe size

(thickness *3, *4)

Pipe length and height difference

*5, *6

Rated

Voltage

Frequency

Indoor/outdoor con

-

necting wire

Gas Liquid

Max. pipe

length

Max. height

difference

Insulation

thickness *7, *8

MFZ-KA25/35VA

230 V 50 Hz

4-core

1.5 mm

2

ø9.52 mm (0.8 mm)

ø6.35 mm

(0.8 mm)

20 m 12 m

8 mm

ø12.7 mm (1.0 mm) 30 m 15 m

MFZ-KA50VA

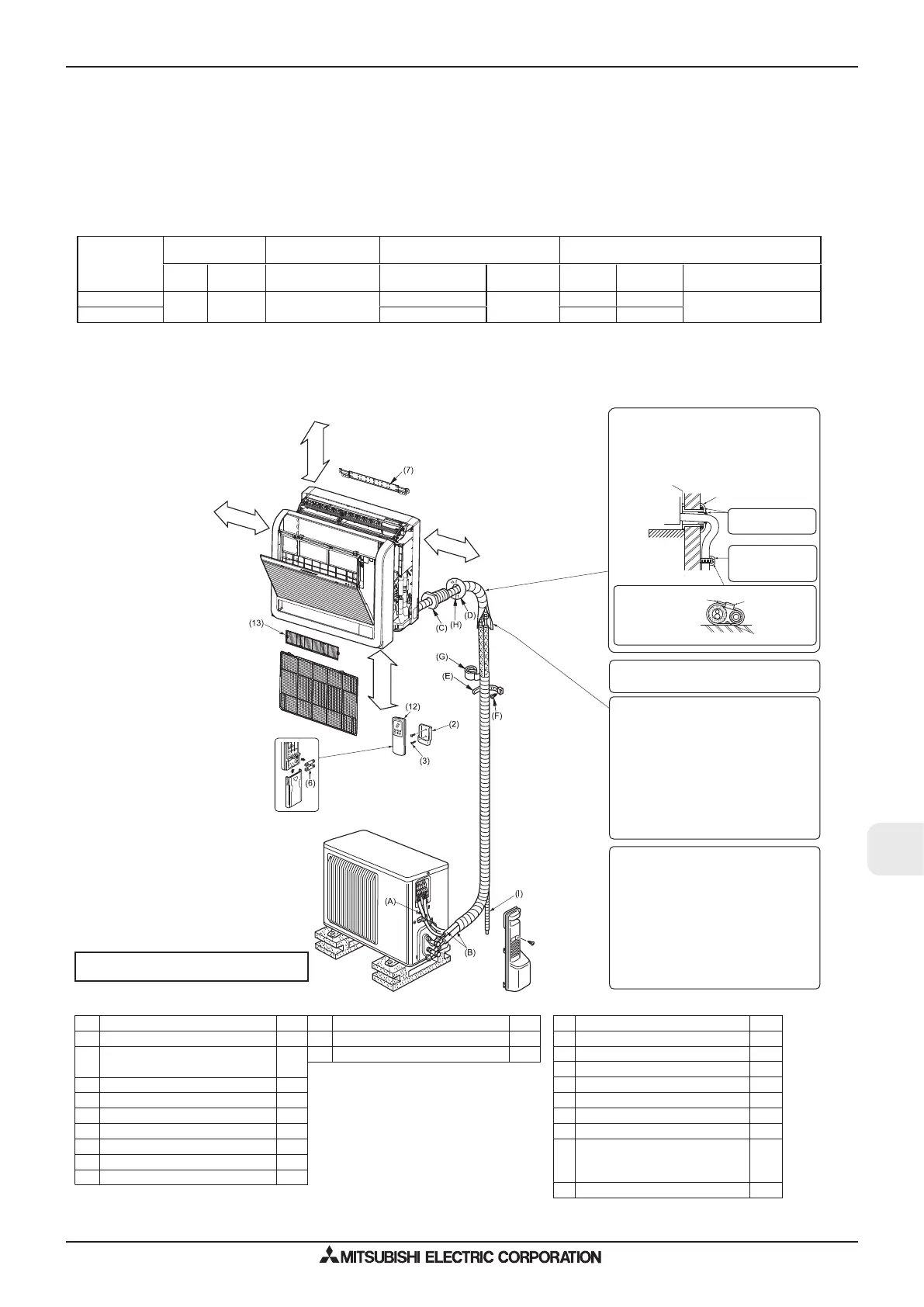

INSTALLATION DIAGRAM

ACCESSORIES

Check

Apprearance of the outdoor unit may differ

from some models.

the following parts before installation.

(1) Drain hose 1

(2) Remote controller holder 1

(3)

Fixing screw for (2) 3.5 × 16 mm

(Black)

2

(4) Pipe cover 1

(5) Band 2

(6) Battery (AAA) for (12) 2

(7) Indoor unit mounting bracket 1

(8) Fixing screw for (7) 4 × 25 mm 5

(9) Wood screw for indoor unit fixation 4

(10) Washer of (9) 4

(11) Felt tape (For left or left-rear piping) 1

(12) Wireless remote controller 1

(13) Air cleaning filter 1

Units should be installed by licensed contractor

according to local code requirements.

Indoor unit

Wall hole

sleeve (C)

Cut off the

extra length.

Pipe fixing band

(E)

Wall hole cover (D)

Seal the wall hole

gap with putty (H).

Fix the pipe to wall

with pipe fixing

band (E).

Fixing screw

(F)

After the leak test, apply insulating mate-

rial tightly so that there is no gap.

When the piping is to be attached to a

wall containing metals (tin plated) or metal

netting, use a chemically treated wooden

piece 20 mm or thicker between the wall

and the piping or wrap 7 to 8 turns of

insulation vinyl tape around the piping.

To use existing piping, perform COOL

operation for 30 minutes and pump down

before removing the old air conditioner.

Remake flare according to the dimension

for new refrigerant.

Be sure to use wall hole sleeve (C) to

prevent indoor/outdoor connecting wire (A)

from contacting metal parts in the wall and

to prevent damage by rodents in case the

wall is hollow.

PARTS TO BE PROVIDED AT YOUR SITE

(A) Indoor/outdoor unit connecting wire* 1

(B) Extension pipe 1

(C) Wall hole sleeve 1

(D) Wall hole cover 1

(E) Pipe fixing band 2 to 5

(F) Fixing screw for (E) 4 × 20 mm 2 to 5

(G) Piping tape 1

(H) Putty 1

(I)

Drain hose

(or soft PVC hose, 15 mm inner

dia. or hard PVC pipe VP16)

1 or 2

(J) Refrigeration oil 1

* Note:

Place indoor/outdoor unit connecting wire (A) and power

supply cord at least 1 m away from the TV antenna wire.

150

mm

or below

from the

floor

SUZ-KA series

100

mm

or

more

100

mm

or

more

100

mm

or

more

Drain piping for outdoor unit

Install the unit horizontally.

Do not use drain socket in cold regions.

Drain may freeze and make the fan stop.

The outdoor unit produces condensate

during the heating operation. Select the in-

stallation place to ensure to prevent the

outdoor unit and/or the grounds from being

wet by drain water or damaged by frozen

drain water.

Loading...

Loading...