-

19

-

'11 • KX-T-166

6 APPLICATION DATA

6.1 Cautions for reuse of existing pipes

①

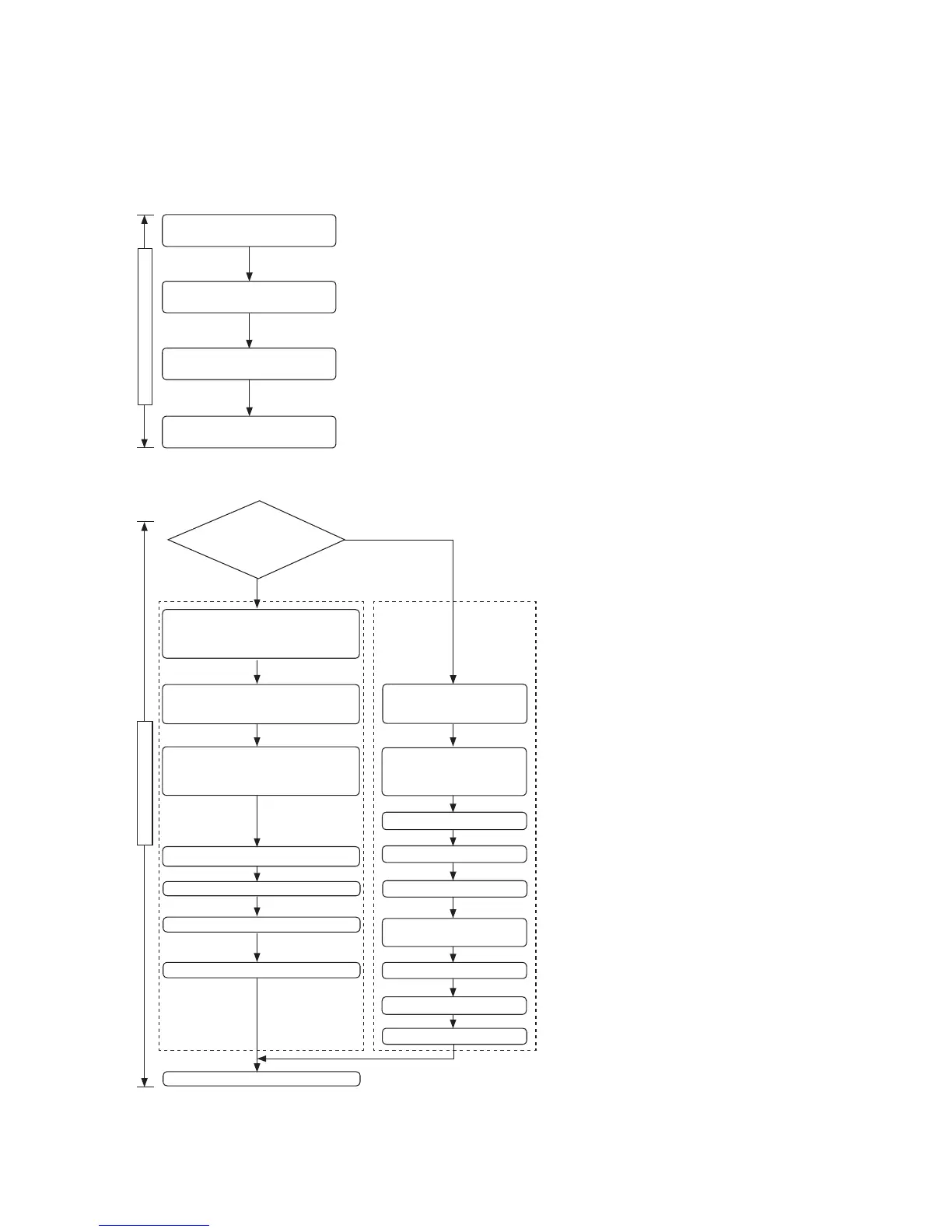

Procedure of installation work for reuse of existing pipes

Check & consideration

Conrmation of reusability of

existing power supply equipment

Conrmation of reusability of

existing control wires

Conrmation of reusability of

existing refrigerant pipes

Conrmation of the scope of

replacement

Before installation work at site

◦

Please note that we cannot warrant the reliability (improper properties owing to

deterioration, etc.) of refrigerant pipes, control wires, electric equipment, etc., for

reuse.

◦

Check existing refrigerant pipes for reusability according to “

②

Flowchart of the

conrmation of reusability of existing pipes”.

◦

Regarding restrictions on the refrigerant pipe length, applicable pipe diameter, etc.,

refer to the product catalogs and manuals.

◦

When reusing existing control wires between outdoor units, indoor units and re

-

mote controller, check them according to “

③

Check and consideration for reuse of

existing wires and power supply equipment”.

◦

Power supply equipment must use the voltage and number of phases adequate for

outdoor units and indoor units and have the circuit breaker capacity and wire diam-

eters as specied on the power supply wiring diagram.

◦

When reusing existing power supply equipment (including power supply wiring),

extent of deterioration of and damages on the equipment must be checked.

◦

When wires or power supply equipment are aged, sufcient care must be taken to

prevent risk of re or earth leakage.

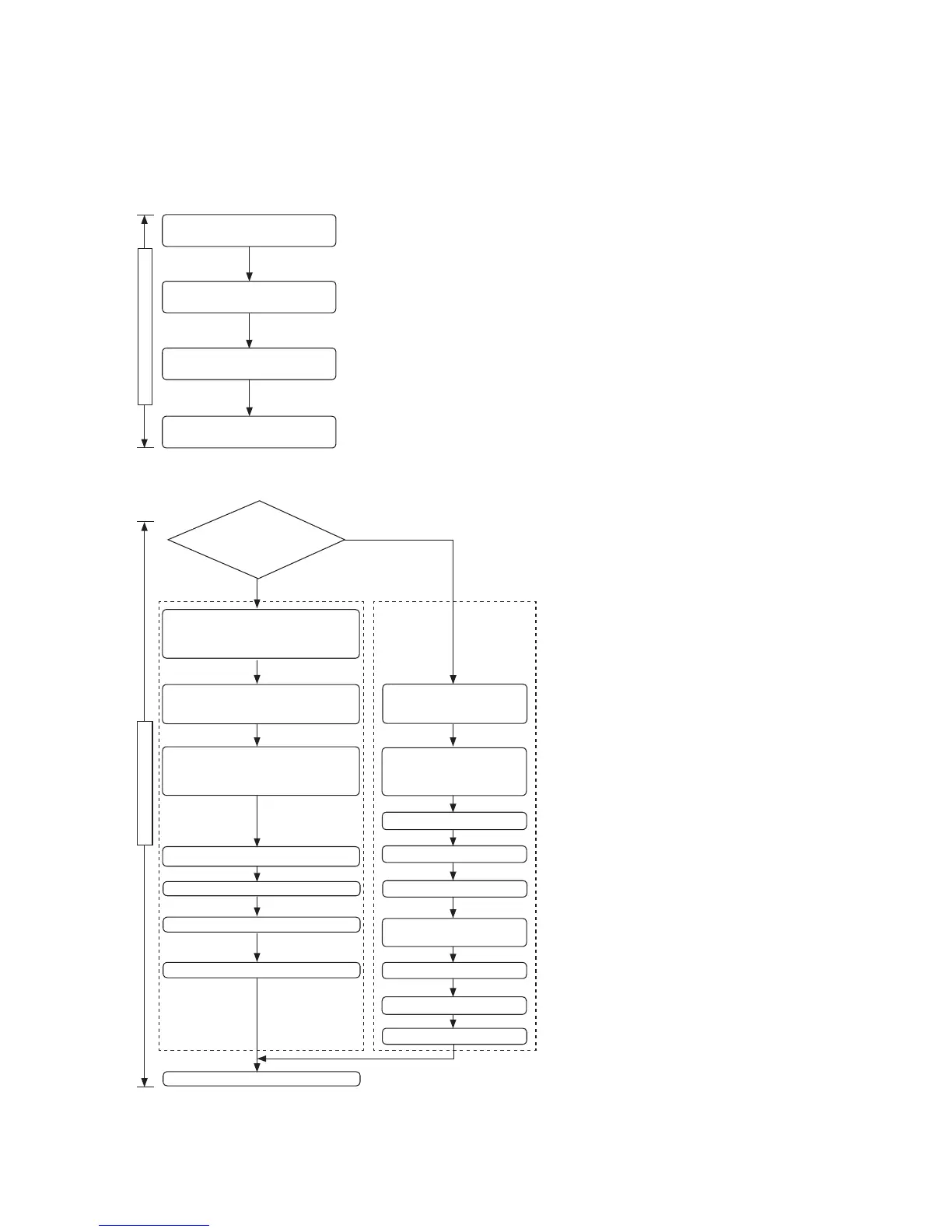

Recovery of old refrigerant and

removal of existing outdoor unit,

indoor unit, remote controller, etc.

Installation of outdoor unit, in-

door unit, remote controller, etc.,

and electrical work <Installation

of service valve kit is necessary.>

Airtight test of pipes

Installation of outdoor unit, indoor

unit, remote controller, etc., and elec-

trical work <Installation of service

valve kit is not necessary.>

Recovery of old refrigerant and re-

moval of existing outdoor unit, indoor

unit, remote controller, etc.

Connection of pipe re-fresh kit

Test run & adjustment

Additional refrigerant charge

System check after the address setting

Vacuumizing of pipes

Existing unit operability

Operable

Not operable

Pipe washing method by cooling

operation of existing unit

Pipe washing method

by re-fresh kit

Airtight test of pipes

Installation work at site

Vacuumizing of pipes

System check after the ad-

dress setting

Additional refrigerant charge

Pipe washing operation using re-fresh kit

Removal of pipe re-fresh kit

Check & consideration

・

If refrigerant cannot be recovered completely with

the pump-down, recover remaining refrigerant using

the refrigerant recovery unit.

・

If the existing unit is not operable, install the ser-

vice valve kit. Make sure to secure a space to install

the re-fresh kit in front of the service valve kit. (500

mm or more in front of the kit)

・

When implementing the pipe washing operation

using the re-fresh kit, consult our dealer.

・

Test the air tightness at 3.24 MPa.

・

Turn the power supply on after the address setting.

Conrm that the system operates properly and that

there is no error display on the remote controller or

indoor unit.

Implementation of pump-down operation after

cooling operation with old system for more than 30

minutes (Existing unit cooling washing operation)

Loading...

Loading...