'21 • SRK-T-299

-

98

-

-

22

-

’20・SRF-DB-310D・

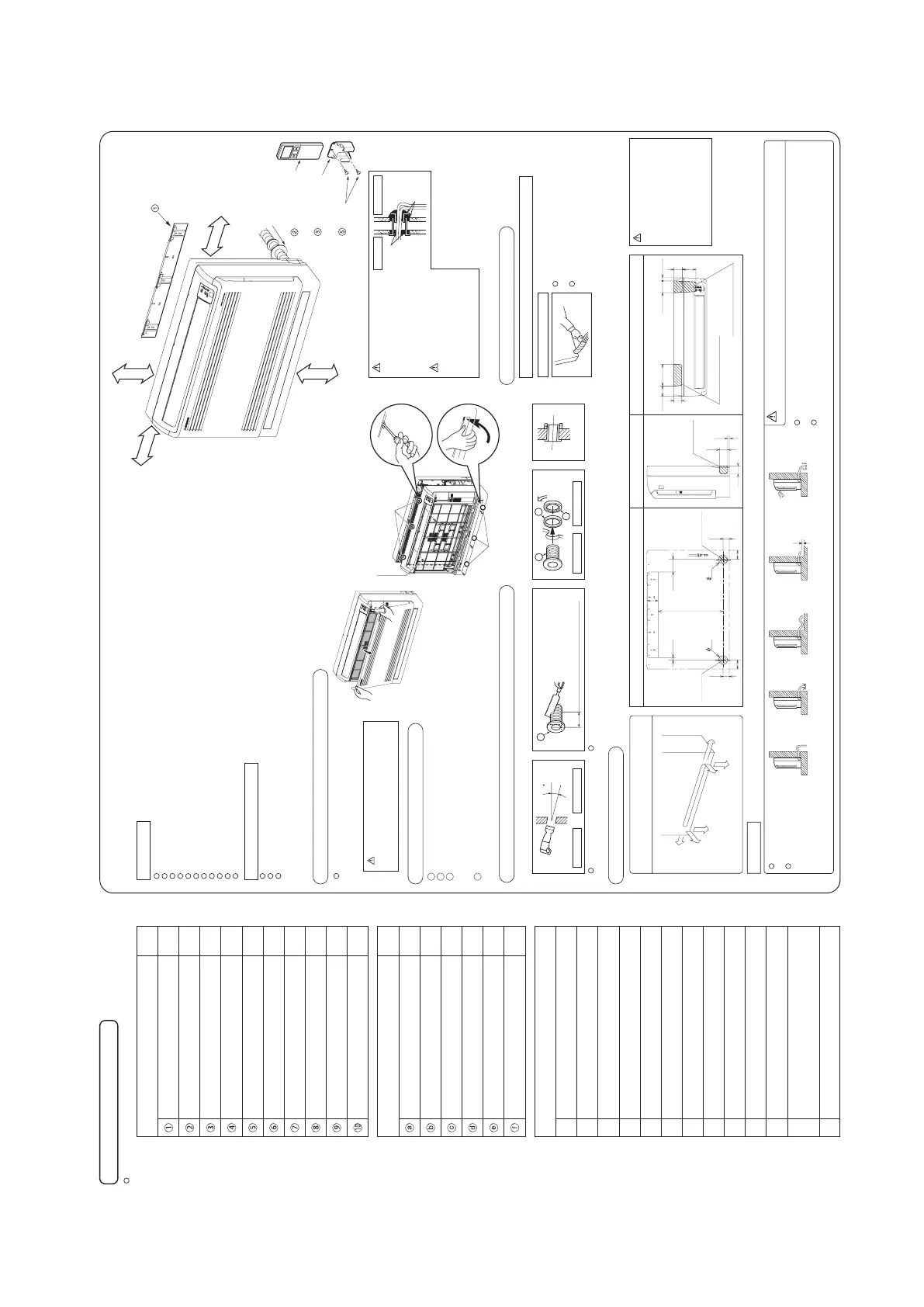

Necessary tools for the installation work

1

2

3

4

5

6

7

8

9

10

11

12

13

1

1

1

1

1

1

Q’ty

Locally procured parts

Sealing plate

Sleeve

Inclination plate

Putty

Drain hose (extension hose)

Piping cover

(for insulation of connection piping)

Plus headed driver

Knife

Saw

Tape measure

Hammer

Spanner wrench

Torque wrench

Hole core drill (65 mm in diameter

)

Wrench key (Hexagon) [4 mm

]

Flaring tool set

Gas leak detector

Pipe bender

Gauge for projection adjustmen

t

Used when flare is made by usin

g

conventional flare tool

()

)

14.0 – 61.0 N·m

(1.4 – 6.1 kgf·m)

(

Designed specifically

for R32 or R410A

)

1

1

1

9

2

2

2

2

1

2

Q’ty

Standard accessories (Installation kit)

Accessories for indoor unit

Installation board

(Attached to the rear of the indoor unit

)

Wireless remote control

Remote control holder

Battery [R03 (AAA, Micro) 1.5 V]

Air-cleaning filters

Filter holders

(Attached to the front panel of indoor unit

)

Pipe cover (200 mm)

Tapping screws

(for installation board ø4 X 25 mm)

Wood screws

(for remote control switch holder ø3.5 X 16 mm)

Band

()

Designed specifically

for R32 or R410A

Before

installation check that the power source matches the air-conditione

r.

Right

Rear

Downward

Left rear

Left downward

Left

60

15

60

60

22.785.3

100

55

157.276.3

For Right or Left rear piping For Right or Left piping

Right/Left

piping

For Right or Left bottom piping

Left bottom piping

Right bottom piping

SELECTION OF INSTALLATION LOCATION

INSTALLATION OF INDOOR UNIT

Indoor unit

Installing the support of piping

(Install at location that meets the following conditions, after getting approval from the customer)

Wireless remote control

In case of piping in the right rear direction

When drilling the wall that contains a metal lath, wire lath or metal plate, be sure to use pipe hole sleeve sold separately.

Taping of the exterior

Top

Thickness of the wall + 1.5 cm

5

ø65

Indoor side Outdoorside

Indoor side Outdoorside

Installed state

Turn to

tighten

b

b

c

a

Open and detachment of the air inlet panel

Drilling of holes and fixture of sleeve (Locally procured parts)

How to remove the front panel

Indoor unit piping direction

CAUTION

Drainage

The drain hose

tip is in water

Higher than

specified

Wavy The gap to the ground

is 5 cm or less

The drain hose tip

is in the gutter

Odor from

the gutter

Where there is no obstructions to the air flow and where the cooled and heated air can be evenly distributed.

A solid place where the unit or the wall will not vibrate.

A place where there will be enough space for servicing. (Where space mentioned right can be secured)

Where wiring and the piping work will be easy to conduct.

The place where receiving part is not exposed to the direct rays of the sun or the strong rays of the street lighting .

A place where it can be easily drained.

A place separated at least 1 m away from the television or the radio. (To prevent interference to images and sounds.)

Places where this unit is not affected by the high frequency equipment or electric equipment.

Avoid installing this unit in place where there is much oil mist.

Places where there is no electric equipment or household under the installing unit.

Install the indoor unit on flat wall.

A place where the air-conditioner can be received the signal surely during operating the wireless remote control.

Places where there is no affected by the TV and radio etc.

Do not place where exposed to direct sunlight or near heat devices such as a stove.

To open, pull the panel at both ends of upper

part and release latches, and undo the strings.

Then remove the panel.

When removing the air inlet panel, be

careful not to drop it on your feet.

CAUTION

Remove the air inlet panel.

Remove the 5 set screws.

Remove the 3 latches in the upper section.

If the latches are difficult to remove, push the latch portion out using a screw

driver, for example.

Move the lower part of the panel forward and remove the 6 latches in the

under section.

1

2

3

4

Installation board

5 cm minimum

from the wall

5 cm + Service space (30 cm)

from the wall

7 cm minimum from the ceiling

15 cm or below

from the floor

Sleeve

(sold separately)

Wireless remote

control

Remote control

holder

Wood

screws

CAUTION

Be careful not to stress the

connecting refrigerant

pipes. (Do not pull with a

force of larger than 5 kgf.)

If improperly installed, it

may cause abnormal noise

and vibration.

Latch

Latch

The screw of the lid is tightened securely.

Drill a hole with whole core drill. In case of rear piping draw out, cut off the lower

and the right side portions of the sleeve collar.

18.5 91.5

45

65

65

65

470

80

65

45

Right rear

piping

Left rear

piping

Piping is possible in the rear, left, left rear,

left downward, right or downward direction.

Tape only the portion that goes through

thewall.

Always tape the wiring with the piping.

Arrange the drain hose

in a downward angle.

Avoid the following

drain piping.

Pour water to the drain pan located under the heat exchanger, and ensure that

the water is discharged outdoor.

When the extended drain hose is indoor, securely insulate it with a heat insulator

available in the market.

Sufficient caremust be taken not to damage

the panel when connecting pipes.

Go through all installation steps and check if the drainage is all right.

Otherwise water leak may occur.

WARNING

putty

putty

Indoor sideOutdoor side

Completely seal the hole in the wall

with putty. If not sealed properly,

dust, insects, small animals, and

highly humid air may enter the room

from outside, which could result in

fire or other hazards.

CAUTION

Completely seal the hole in the wall

with putty. If not sealed properly,

furniture and other fixtures may be

damaged by water leakage or

condensation.

-

23

-

’20・SRF-DB-310D・

(860)

103.5

726

30.5

25.5

585

5

585

595

(600)

30.5

(238)

198

185

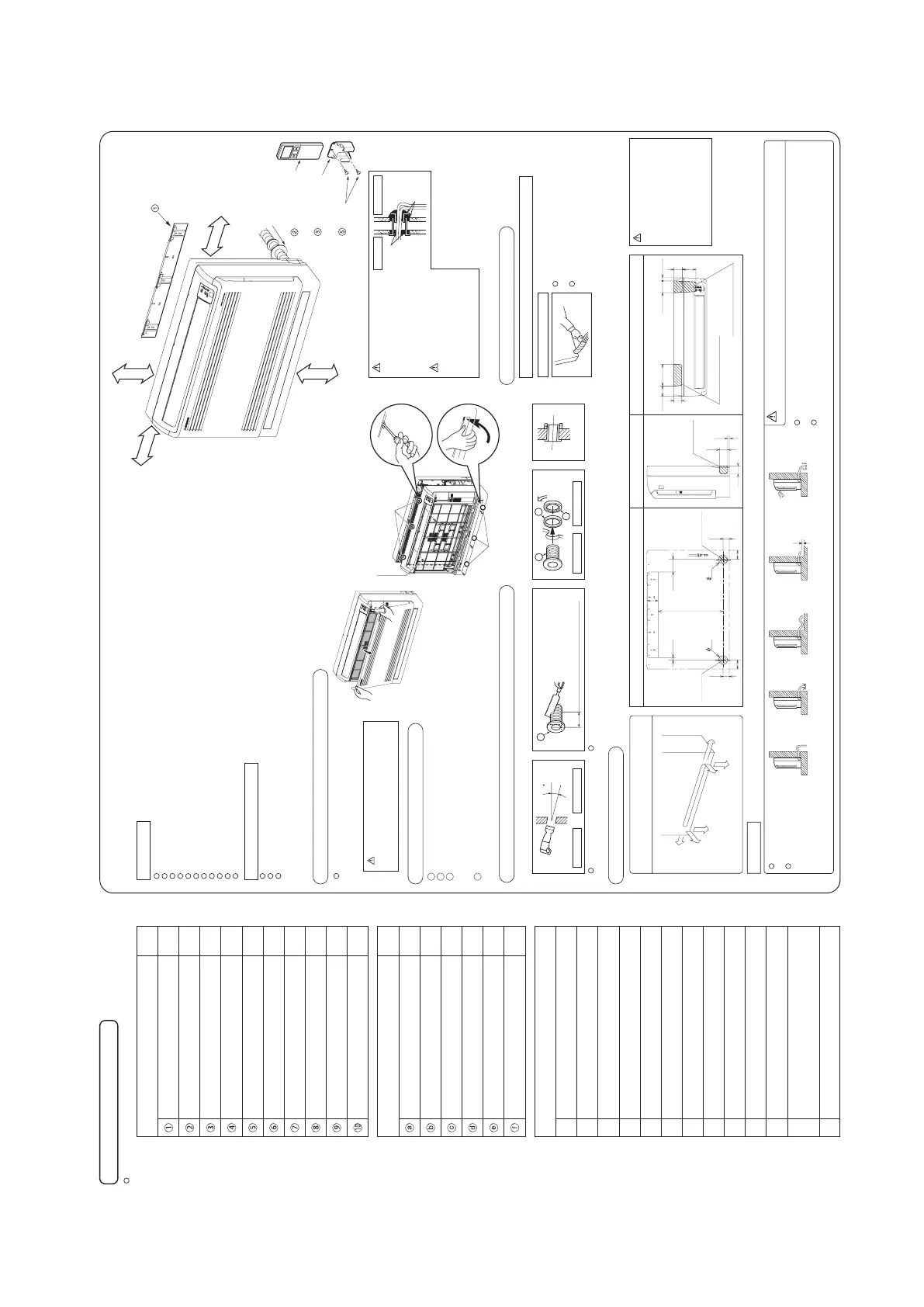

Installation of Installation board

Fixing on concrete wall

Use of nut anchor

Installation

board

Bolt

(M6 12)

Standard hole

Fixing of indoor unit

Floor installation Wall installation

Tapping screw

(860)

103.5

156.5

726

585

5

585

595

(600)

30.5

83.5

(238)

CAUTION

• During the installation, do not lean on the control box or the display, as they may be damaged.

• Install the indoor unit on flat wall. If improperly installed, it may cause abnormal noise and vibration. (Distortion on the wall shall be no larger than 3 mm.)

Secure using upper 2 screws for floor installations.

If possible, also attach two lower screws.

At first secure the installation board using 5 screws and the indoor unit using 2 screws.

Look for the inside wall structures (Intermediate

support or pillar and finally install the unit after

level surface has been checked.)

When practicing the half-console, make sure to fix the unit securely.

Otherwise, it could fall.

Adjustment of the installation board in the

horizontal direction is to be conducted with five

screws in a temporary tightened state.

Adjust so the board will be level by turning the

board with the standard hole as the center.

If there is an obstacle such as a

cable cover, cut off the hatched

part before installation.

Refrigerant

pipe

Slit

Refrigerant

pipe

Slit

Tape

Refrigerant

pipe

155

45

105

130

140

CONNECTION OF REFRIGERANT PIPINGS

Preparation

Indoor

(Do not turn)

Press

Remove

90s0.5˚

Dimension A (mm)

Liquid side φ6.35 : 9.1

Gas side

φ9.52 : 13.2

φ12.7 : 16.6

Measurement B

Flaring

block

Copper pipe

Connection

Finishing work and fixing

Insulation of the connection portion

Indoor

Liquid side

Gas side

(Do not turn)

Connection wiring,

Earth wiring

Outer tape

Refrigerant piping

Drain hose

Wood screw

Clamp

Install the removed flared nuts to the pipes to

be connected, then flared the pipes.

Remove the flared nuts. (on both liquid and

gas sides)

CAUTION

Do not apply refrigerating machine oil to the flared surface.

• Flaring work

Copper pipe

diameter

Conventional (R22) flare tool

φ6.35

φ9.52

φ12.7

0.0 - 0.5

0.0 - 0.5

0.0 - 0.5

1.0 - 1.5

1.0 - 1.5

1.0 - 1.5

1.5 - 2.0

1.5 - 2.0

2.0 - 2.5

Measurement B (mm)

Clutch type Wing nut type

Use a flare tool designed for R32, R410A or a conventional flare tool.

Note that measurement B (protrusion from the flaring block)

will vary depending on the type of a flare tool in use.

Keep the openings of the pipes covered with tapes etc.

to prevent dust, sand, etc. from entering them.

Connect the pipes on both liquid and gas sides.

Tighten the nuts to the following torque.

Liquid side (φ6.35) : 14.0 - 18.0 N·m (1.4 - 1.8 kgf·m)

Gas side (φ9.52) : 34.0 - 42.0 N·m (3.4 - 4.2 kgf·m)

(φ12.7) : 49.0 - 61.0 N·m (4.9 - 6.1 kgf·m)

CAUTION

Do not apply excess torque to the flared nuts.

Otherwise, the flared nuts may check depending.

CAUTION

Be careful not to stress the connecting refrigerant

pipes. (Do not pull with a force of larger than 5 kgf.)

Cover the exterior portion with

outer tape and shape the piping

so it will match the contours of

the route that the piping to take.

Also fix the wiring and pipings to

the wall with clamps.

ELECTRICAL WIRING WORK

Preparation of indoor unit

Terminal block

Sensor

Fixing screw

Clamp

Wiring holder

Remove the fixing screw of clamp.

Connect the connecting wire securely to the terminal block.

1) Connect the connection wire securely to the terminal

block. If the wire is not affixed completely, contact will be

poor, and it is dangerous as the terminal block may heat

up and catch fire.

2) Take care not to confuse the terminal numbers for indoor

and outdoor connections.

Fix the connecting wire by wiring clamp.

Pass the connecting wire through the wiring holder.

1

2

3

4

H05RNR4G1.5 (example) or 245IEC57

H

05

R

N

R

4 or 5

G

1.5

Harmonized cable type

300/500 volts

Natural-and/or synth, rubber wire insulation

Polychloroprene rubber conductors insulation

Stranded core

Number of conductors

One conductor of the cable is the earth conductor

(yellow/green)

Section of copper wire (mm

2

)

Mounting of connecting wires

CAUTION

• During installation, do not lean on the control box or the

display, as they may be damaged.

• Pass the connecting wire securely through the wiring holder.

If it passeson the sensor, it may not detect suction

temperature and/or humidity.

• Earth wire shall be Yellow/Green (Y/G)

in color and longer than other AC wires

for safety reason.

• Cover the indoor unit’s flare-connected joints, after

they are checked for a gas leak, with an indoor unit

heat insulating material and then wrap them with a

tape with an attached pipe cover placed over the

heat insulating material’s slit area.

Use cables for interconnection wiring to avoid loosening of the wires.

CENELEC code for cables Required field cables.

Pass the refrigerant pipe

through the piping hole to

indoor side.

Arrange the pipes according

to the direction of piping.

Cover the coupling with insulator and then cover it with tapes.

Use an attached pipe cover for heat insulation.

Position it so that the slit area faces upward.

Add

band

10

Pipe cover

9

CAUTION

If heat insulation is insufficient, water leakage may

occur. In addition, the room temperature sensor

may give a false alert due to heat radiation from

the pipes.

A

Clutch type flare tool

for R32 or R410A

If a conventional flare tool is used, use a copper pipe gauge or a

similar instrument to check protrusion so that you can keep

measurement B to a correct value.

In case of faulty wiring connection, the indoor unit stops, and then

the run lamp turns on and the timer lamp blinks.

Loading...

Loading...