-

17

-

'18 • SCM-T-251

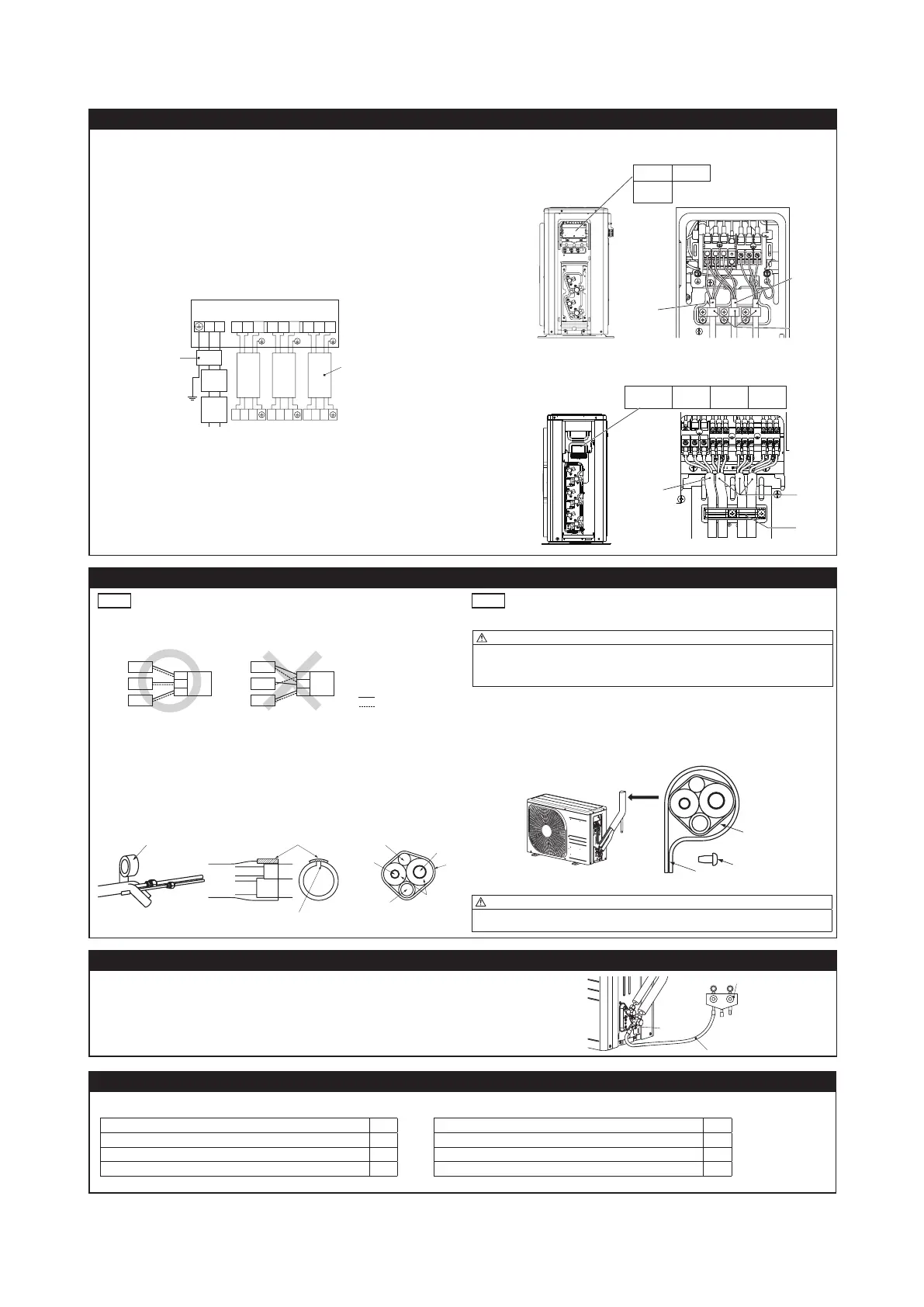

4. CONNECTING PIPING WORK

1. Restrictions on unit installation

Abide by the following restrictions on unit installation.

Improper installation can cause compressor failure or performance degradation.

Model SCM40/45 Model SCM50/60

piping length

one indoor unit MAX 25m

all indoor unit MAX 30m

one indoor unit MAX 25m

all indoor unit MAX 40m

hight difference

MAX

25m

MAX 15m

MAX 15m

outdoor

unit

indoor

unit

indoor

unit

MAX

25m

MAX 15m

MAX 15m

outdoor

unit

indoor

unit

indoor

unit

indoor

unit

2. Preparation of connecting pipe

2.1. Selecting connecting pipe

Select connecting pipe according to the following table.

Indoor unit Model 20/25/35 Model 50/60

Gas pipe ø9.52 ø12.7

Liquid pipe ø6.35 ø6.35

• Pipe wall thickness must be greater than or equal to 0.8 mm.

• Pipe material must be O-type (Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS

77.150.30).

2.2. Cutting connecting pipe

(1) Cut the connecting pipe to the required length with pipe cutter.

(2) Hold the pipe downward and remove the burrs. Make sure that no foreign material enters the pipe.

(3) Cover the connecting pipe ends with the tape.

3. Piping work

Check that both liquid and gas service valves are fully closed.

Carry out the piping work with service valves fully closed.

Liquid service valve

Gas service valve

3.1. Flaring pipe

(1) <SCM40/45>

Takeoutflarenutsfromtheservicevalvesofoutdoorunitandengagethemontoconnectingpipes.

<SCM50/60>

Takeoutflarenutsfromtheservicevalvesofoutdoorunit.

Ifa5.0,6.0kWclassindoorunit(gassidepipe12.7)isgoingtobeconnectedtotheservicevalves

(9.52), variable joints available as accessories must be applied to the gas side service valves.

Securelyfitthecopperpackingbetweentheservicevalveandthevariablediameterjointto prevent

shifting.

Engageflarenutsontoconnectingpipes.

Liquid side service valve ( 6.35)

6.35 pipe

50,60 model

Indoor unit

Gas side service

valve (

9.52)

Copper packing

Variable diameter joint

12.7 pipe

(2) Flarethepipesaccordingtotableandgureshownbelow.

Flare dimensions for R410A are different from those for conventional refrigerant.

AlthoughitisrecommendedtousethearingtoolsdesignedspecicallyforR410A,conventionalaring

toolscanalsobeusedbyadjustingthedimensionBwithaareadjustmentgauge.

Copperpipe

outer diameter

A

B

Copperpipe

outer diameter

B [Rigid (clutch) type]

R410A Conventional

ø6.35 9.1 ø6.35

0-0.5 1.0-1.5ø9.52 13.2 ø9.52

ø12.7 16.6 ø12.7

3.2. Connecting pipes

(1) Connect pipes on both liquid and gas sides.

<SCM40/45> <SCM 50/60>

Service valve

for room B

Service valve

for room A

Service valve

for room C

Service valve

for room B

Service valve

for room A

(2) Tightennutstospeciedtorqueshowninthetablebelow.

Service valve size (mm) Tightening torque (N·m)

ø6.35 (1/4") 14-18

ø9.52 (3/8") 34-42

ø12.7(1/2") 49-61

Do not hold the valve cap area with a spanner

CAUTION

• Donotapplyrefrigeratingmachineoiltothearedsurface.Itcancauserefrigerantleakage.

• Donotapplyexcesstorquetothearednuts.Thearednutsmaycrackresultinginrefrigerantleakage.

4. Evacuation

(1) Connect vacuum pump to gauge manifold. Connect charge hose of gauge manifold to a service port

of outdoor unit.

(2) Runthevacuumpumpforatleastonehourafterthevacuumgaugeshows-0.1MPa(–76cmHg).

(3) Confirmthatthevacuumgaugeindicatordoesnotriseevenifthesystemisleftfor15minutesormore.

Vacuum gauge indicator will rise if the system has moisture left inside or has a leakage point. Check

the system for the leakage point. If leakage point is found, repair it and return to (1) again.

(4) Close the Handle Lo and stop the vacuum pump.

Keep this state for a few minutes to make sure that the compound pressure gauge pointer does not

swing back.

(5) Remove valve caps from liquid operation valve and gas service valve.

(6)

(7)

Turn the liquid operation valve's rod 90 degree counterclockwise with a hexagonal wrench key to

open valve.

Close it after 5 seconds, and check for gas leakage.

Usingsoapywater,checkforgasleakagefromindoorunit'sareandoutdoorunit'sareandvalverods.

Wipe off all the water after completing the check.

Disconnectcharginghosefromgasservicevalve'sserviceportandfullyopenliquidandgasop-

eration valves. (Do not attempt to turn valve rod beyond its stop.)

(8) Tightenservicevalvecapsandserviceportcaptothespecifiedtorqueshowninthetablebelow.

Service valve size (mm)

Service valve cap tightening

torque (N·m)

Service port cap tightening

torque (N·m)

ø6.35 (1/4")

20-30

10-12ø9.52 (3/8")

ø12.7(1/2") 25-35

(9) Repeat the above steps (1) to (8) for all connected indoor units.

Handle Lo

Valve cap

Liquid service valve

Gas service valve

Service port

Pressure gauge

Gauge manifold

Handle Hi

Vacuum pump

CAUTION

Topreventvacuumpumpoilfromenteringintotherefrigerantsystem,useacounterowpreventionadapter.

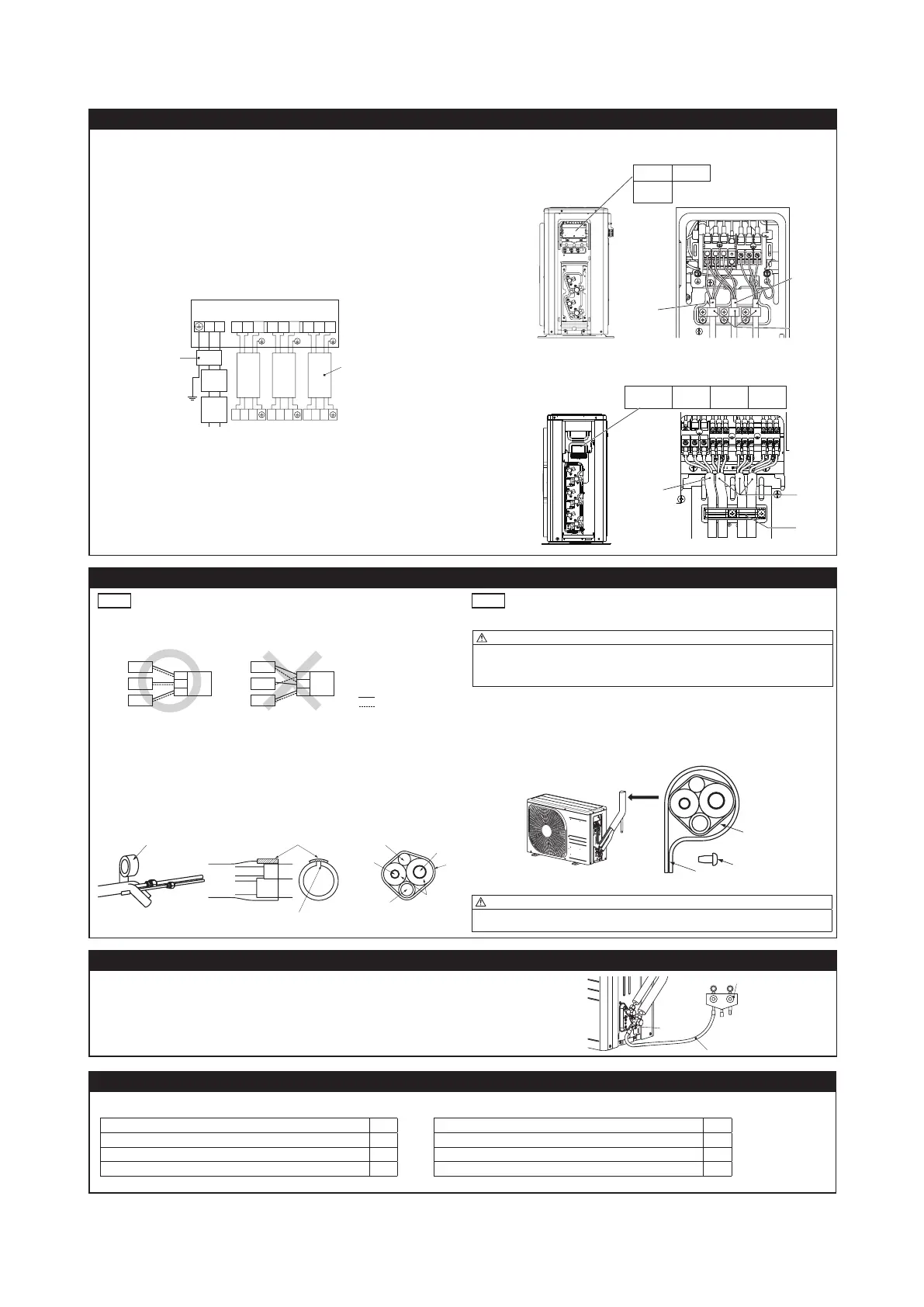

5. ELECTRICAL WIRING WORK

WARNING

• Make sure that all the electrical work is carried out in accordance with the national or regional electri-

cal standards.

• Make sure that the earth leakage breaker and circuit breaker of appropriate capacities are installed

(Refer to the table given below).

•

Do not turn on the power until the electrical work is completed.

• Do not use a condensive capacitor for power factor improvement under any circumstances.

(It does not improve power factor. Moreover, it can cause an abnormal overheat accident).

Breakerspecications

Model Phase Earth leakage breaker Circuit breaker

SCM40/45/50/60 Single phase

Leakage current: 30mA,

0.1sec or less

Over current: 25A

Mainfusespecication

Model Specication Parts No.

SCM40/45 250V 15A SSA564A136

SCM50/60 250V 20A SSA564A136A

1.Preparing cable

(1) Selecting cable

Selectthepowersourcecableandconnectingcableinaccordancewiththespecicationsmentionedbelow.

(a) Power source cable

3-core* 2.5mm

2

ormore,conformedwith60245IEC57

When selecting the power source cable length, make sure that voltage drop is less than 2%.

If the wire length gets longer, increase the wire diameter.

(b) Connecting cable

4-core* 1.5mm

2

,conformedwith60245IEC57

* 1 Earth wire is included (Yellow/Green).

(2) Arrange each wire length as shown below.

Make sure that each wire is stripped 10mm from the end.

<Power source cable> <Connecting cable> <Wire end>

(3) Attach round crimp-type terminal to each wire as shown in the below.

Selectthesizeofroundcrimp-typeterminalafterconsideringthespecicationsofterminalblockandwire

diameter.

Round crimp-type terminal

Sleeve

CAUTION

Powersourcecableandconnectingcablemustconformtothespecicationsmentionedinthemanual.

Usingcableswithwrongspecicationsmayresultinunitmalfunction.

5. ELECTRICAL WIRING WORK

2.Connecting cable

(1) Remove the service cover and the terminal cover.

(2) Connectthecablesaccordingtotheinstructionsandguresgivenbelow.

(a) Connect the earth wire of power source cable.

An earth wire must be connected before connecting the other wires of power source cable.

Keep the earth wire longer than the remaining two wires of power source cable.

(b) Connect the remaining two wires (N and L) of power source cable.

(c) Connect the wires of connecting cables. Make sure that for each wire, outdoor and indoor side ter-

minal numbers match. Terminal number A of the outdoor unit is used for A indoor unit and terminal

number B for B indoor unit respectively.

Earth wire shall be Yellow/Green (Y/G) in color and longer than other wires for safety reason.

(3) Fasten the cables properly with cable clamps so that no external force may work on terminal connec-

tions.

Moreover, make sure that cables do not touch the piping, etc. When cables are connected, make sure

that all electrical components within the electrical component box are free of loose connector coupling

or terminal connection.

<Circuit diagram>

NL

Circuit

breaker

Earth

leakage

breaker

Earth

Power

Outdoor unit

Power

source

cable

Indoor unit

123

123

123

unit A

unit B

unit C

unit Aunit B

1 2 3 1 2 3 1 2 3

unit C

Connecting cable

<SCM40/45>

View of terminal block

unit A unit B

Power

source

<SCM 50/60>

View of terminal block

Power

source

unit A unit B unit C

6. FINISHING WORK

NOTE

●

Make sure to match the piping and wiring from each unit to the outdoor unit.

●

Be careful because if connections are wrong, normal operation cannot be achieved and may damage the

compressor.

Wiring

Indoor unit

unit C

unit B

unit A

Outdoor

unit

C

A

B

unit C

unit B

unit A

Outdoor

unit

C

A

B

1. Heating and condensation prevention

(1) Dress the connecting pipes (both liquid and gas pipes) with insulation to prevent it from heating

and dew condensation.

Use the heat insulating material which can withstand 120°C or higher temperature. Make sure that

insulation is wrapped tightly around the pipes and no gap is left between them.

(2) Wrap the refrigerant pipings of indoor unit with indoor unit heat insulation using tape.

(3) Covertheare-connectedjoints(indoorside)withtheindoorunitheatinsulationandwrapitwith

an insulation pad (standard accessory provided with indoor unit).

(4) Wrap the connecting pipes, connecting cable and drain hose with the tape.

(2) (3) (4)

Insulation pad

Position it so that the slit area faces upward.

Connecting cable

Liquid pip

e

Insulation

Tape

NOTE

Locationswhererelativehumidityexceeds70%,bothliquidandgaspipesneedtobedressed with20mm

or thicker heat insulation materials.

CAUTION

• Improper insulation can cause condensate(water) formation during cooling operation.

Condensate can leak or drip causing damage to household property.

• Poor heat insulating capacity can cause pipe outer surface to reach high temperature during heating

operation. It can cause cable deterioration and personal injury.

2.Finishing work

(1) Make sure that the exterior portion of connecting pipes, connecting cable and drain hose is wrapped

properly with tape. Shape the connecting pipes to match with the contours of the pipe assembly route.

(2) Fix the pipe assembly with the wall using clamps and screws. Pipe assembly should be anchored ev-

ery 1.5m or less to isolate the vibration.

(3) Install the terminal cover and the service cover securely. Water may enter the unit if service cover is

not installed properly, resulting in unit malfunction and failure.

Screw

CAUTION

Make sure that the connecting pipes do not touch the components within the unit. If pipes touch the

internal components, it may generate abnormal sounds and/or vibrations.

7. PUMP DOWN

(1) Connect charge hose of gauge manifold to a service port of outdoor unit.

(2) Close the liquid operation valves for all connected indoor units with hexagonal wrench key.

(3) Fully open the gas operation valves with hexagonal wrench key.

(4) Carry out forced cooling operation for all connected indoor units (For forced cooling operation procedure,

refer to indoor unit installation manual).

(5) When the low pressure gauge becomes 0.01MPa, close the gas service valves and stop forced cooling

operation.

Gauge manifold

Charge hose

Service port

8. INSTALLATIONTESTCHECKPOINTS

Afternishingtheinstallationwork,checkthefollowingpointsagainbeforeturningonthepower.

Conduct test run (Refer to indoor unit installation manual) and ensure that the unit operates properly.

Power source voltage complies with the rated voltage of air-conditioner.

Earth leakage breaker and circuit breaker are installed.

Powercableandconnectingcablearesecurelyxedtotheterminalblock.

Both liquid and gas service valves are fully open.

No gas leaks from the joints of the service valves.

Indoor and outdoor side pipe joints have been insulated.

Drainhose(ifinstalled)isxedproperly.

Screw of the service cover is tightened properly.

Connecting

cable

Power

source

cable

Cable clamp

Connecting

cable

Power

source

cable

Cable clamp

Loading...

Loading...