Loading...

Loading...

Do you have a question about the Mitsubishi Heavy Industries SCM60ZF-S and is the answer not in the manual?

| Cooling Capacity | 6.0 kW |

|---|---|

| Power Supply | 220-240 V, 50 Hz |

| Indoor Unit Dimensions (W x H x D) | Varies depending on the indoor unit model selected |

| Weight (Indoor Unit) | Varies depending on the indoor unit model selected |

| Indoor Unit Noise Level | Varies depending on the indoor unit model selected |

Details on piping length, connectable units, and inverter control.

Explanation of the model naming convention for units.

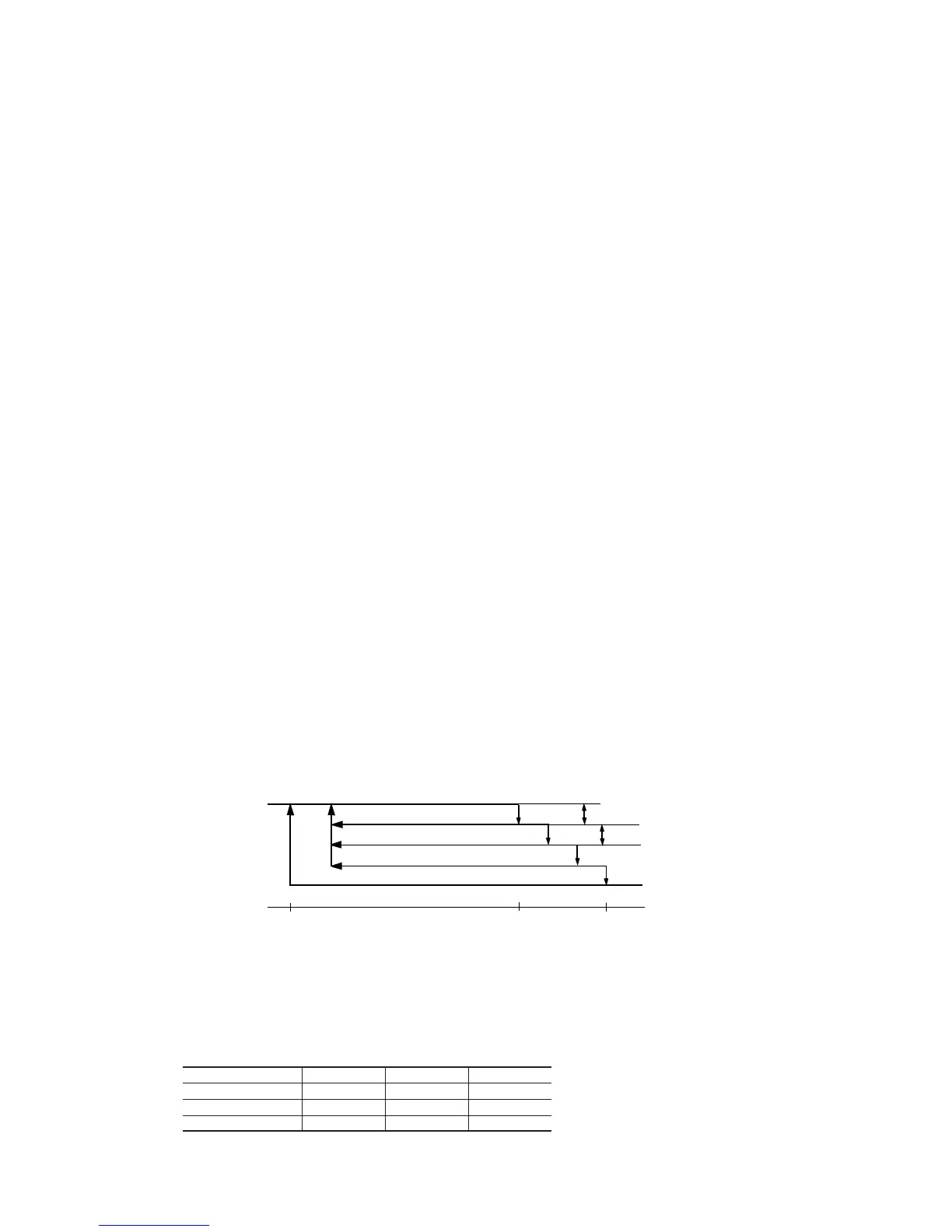

Technical specifications for indoor and outdoor units, including capacities and dimensions.

Defines the operational limits for indoor and outdoor temperatures and piping.

Provides detailed physical dimensions for indoor and outdoor units.

Illustrates the refrigerant piping layout for different models.

Charts for correcting capacity based on temperatures and piping length.

Explains symbols used for components in outdoor and indoor units.

Wiring diagrams for indoor units, outdoor units, and remote controls.

Details on using wireless and wired remote controls, unit indicators, and buttons.

Explains the function of the unit's physical ON/OFF button.

Procedures for forced operation of the drain motor in specific models.

Describes the function that resumes operation after a power cut.

Instructions on adjusting the air direction flap using the remote control.

Details on setting the comfortable timer for operation start time.

Information on cooling operation modes and fan speed control.

Details various protective functions like frost prevention, overload, and compressor controls.

Information on heating operation modes and fan speed control.

Explains how the unit determines and changes operation modes automatically.

Illustrates how operating modes are determined and switched.

Covers external control outputs and input signal control for specific models.

Explains how to control operation using jumper wires and external signals.

Critical safety warnings and cautions for installation and handling.

Instructions for mounting and installing various indoor unit types (SKM, STM, SRRM).

Procedures for installing the remote control and its accessories.

Guidelines for selecting installation location and mounting outdoor units.

Instructions for connecting power lines and crossover wires for units.

Information on pipe limits, diameters, connection, and additional charge.

Steps for performing test runs and initial handling after installation.

Instructions for installing optional ducted type parts like grilles and filters.

Comprehensive guide for diagnosing and resolving operational issues with self-diagnosis.

Procedures for evacuation and refrigerant charging during servicing.

Information on R410A refrigerant, its characteristics, and safety.

Precautions for safe installation and servicing with R410A.

Details on piping materials, joints, processing, and brazing for R410A.

Covers tools for R410A, new installation, replacement, and retrofitting.

Procedures and tools for recovering R410A refrigerant safely.