'09•SRK-DB-087D

(9) Checking the indoor electrical equipment

(a) Indoor PCB check procedure

(b) Outdoor unit

Is there voltage between terminal

blocks

①

and

②

? (AC 220/230/240

V)

Indoor electrical components

are normal.

Is the voltage between terminal

blocks

②

and

③

oscillating between

DC 0 and 20V?

Inspect power source

for outdoor unit.

Replace fuse.

Replace indoor PCB.

Is the fuse burnt out? (3.15 A)

YES

YES

YES

NO

NO

NO

(b) Indoor unit fan motor check procedure

1) Indoor PCB output check

① ④ ⑤

2) Fan motor resistance check

⑥ ⑤ ④ ③ ② ①

⑥ ⑤ ④ ③ ② ①

FM

I

DC15V

Indoor PCB

DC 308~336V

DC several V

(4~6 V)

CNU

(–)

GND

Blue

Yellow

White

Black

Red

Sensor

Operation

mode

Phenomenon

Shortcircuit Disconnected wire

Heat exchanger

sensor

Cooling

Heating

Ourdoor air

temperature sensor

Cooling

Heating

Discharge pipe

sensor

All modes

Measuring point Resistance when normal

①

−

③

−

④

−

③

−

Measuring

point

Resistance when

normal

①

−

③

④

−

③

⑤

−

③

⑥

−

③

Defrosting is performed for 10 minutes at approx. 45 (models 50, 60 : 35) minutes.

Defrosting is performed for 10 minutes at approx. 45 (models 50, 60 : 35) minutes.

'09•SRK-DB-087D

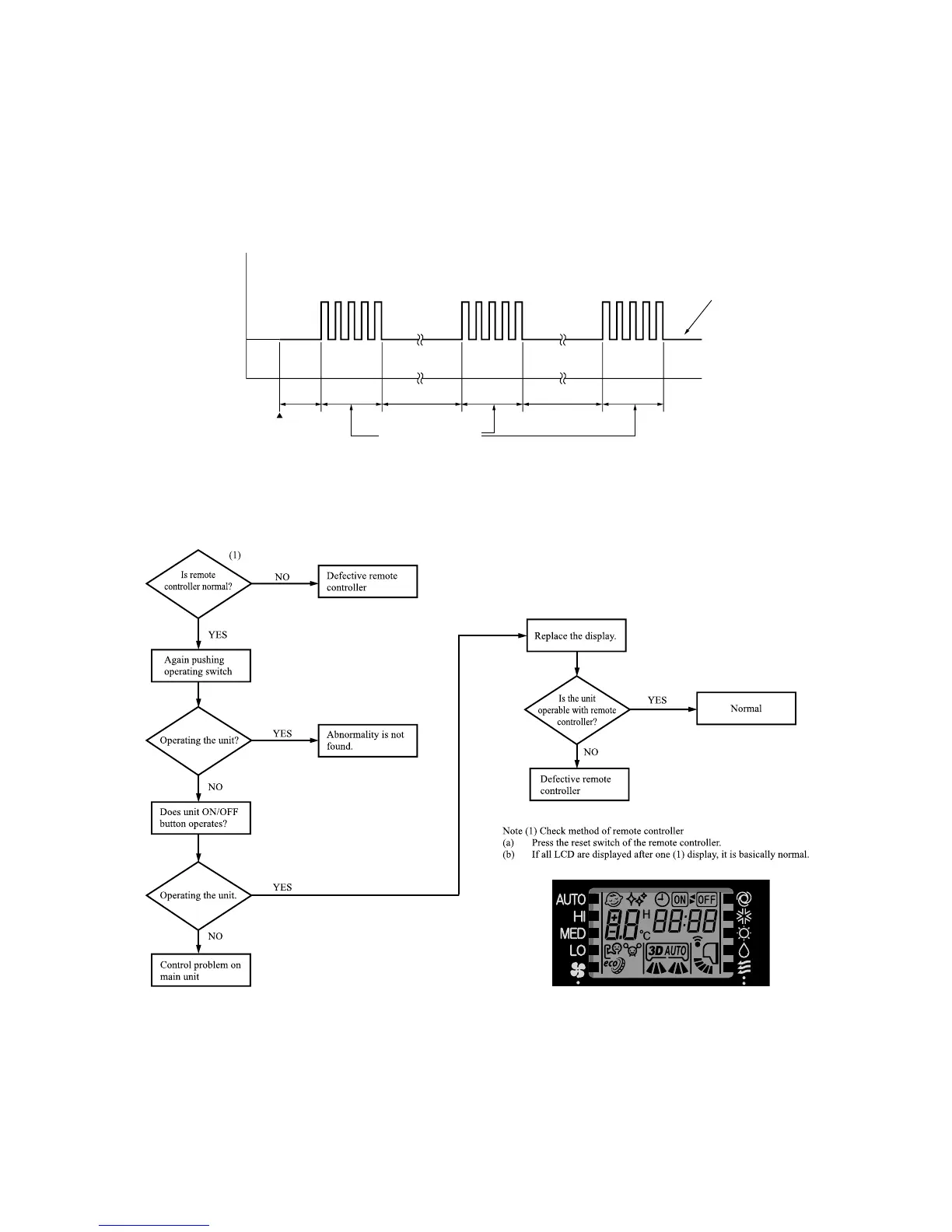

(10) How to make sure of wireless remote controller

(C) Power transistor inspection procedure

[Use a tester with a needle indicator for the inspection. (Do not use a digital tester. Check in the AC 300 volt range.)]

(1) If there is a self-diagnosis display, inspect the compressor system (burns, wiring mistakes, etc.) If no problems are found, check the

output of the power transistor.

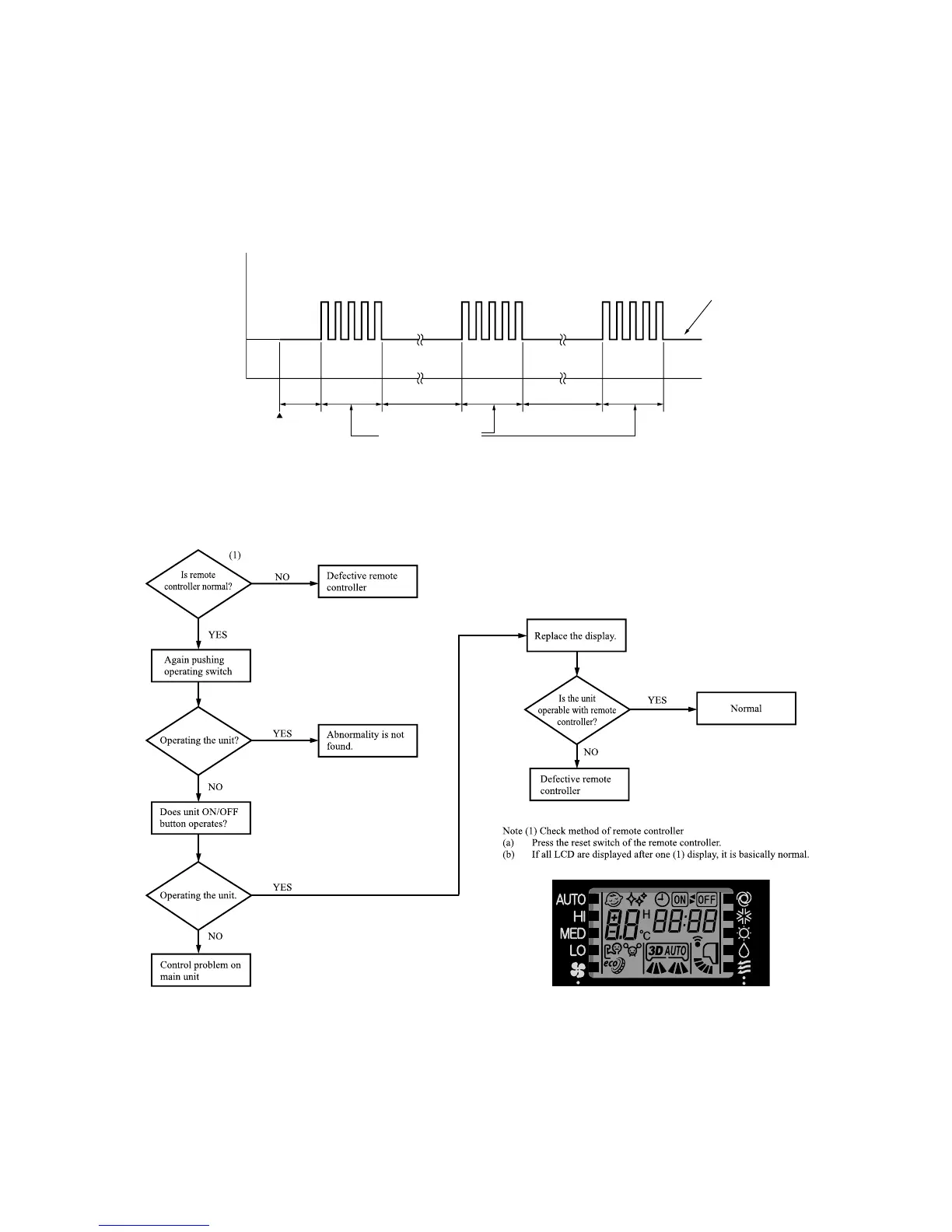

(2) Output inspection procedure

Disconnect the terminals for the compresseor.

If an output such as the one shown in the figure on the below can be measured, the power transistor and the circuit board for the

outdoor unit are normal.

(Example)

RUN light : ON

TIMER light: 2 time flash

Measure in this section

Operation SW ON

8~10 sec. 1 sec. 1 sec.

3 min. 3 min.

1 sec.

0

Output voltage

(ACV)

The figare below shows the SRK series.

Loading...

Loading...