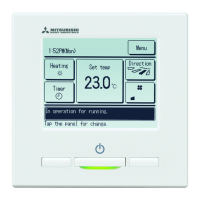

Minimum amount of water required in the space

heating circuit

Outdoor heat pump unit Minimum water quantity [L]

Packaged model PUHZ-W50 40

PUHZ-W85 60

PUHZ-HW112 80

PUHZ-HW140 100

Split model PUHZ-RP35 32

PUHZ-RP50 40

PUHZ-RP60 50

PUHZ-(H)RP71 60

PUHZ-(H)RP100 80

PUHZ-(H)RP125 100

PUHZ-RP140 120

PUHZ-SW40 32

PUHZ-SW50 40

PUHZ-SW75 60

PUHZ-SW100 80

PUHZ-SW120 120

PUHZ-SHW80 60

PUHZ-SHW112 80

PUHZ-SHW140 100

<Table 4.2.1>

4.2 Water Quality and System Preparation

General

• Water quality should be to European Directive 98/83 EC standards.

► pH value of 6.5-8.0 (Recommended: pH6.5 - 7.5)

► Calcium ≤ 100 mg/l

► Chlorine ≤ 100 mg/l

► Iron/Manganese ≤ 0.5 mg/l

• In known hard water areas, to prevent/minimise scaling, it is benecial to restrict

the routine stored water temperature (DHW max. temp.) to 55°C.

Anti-Freeze

Anti-freeze solutions MUST use propylene glycol with a toxicity rating of Class 1 as

listed in Clinical Toxicology of Commercial Products, 5th Edition.

N

ote: Ethylene glycol is toxic and must N

OT be used in the primary water

circuit in case of any cross-contamination of the potable circuit.

New Installation (primary water circuit)

• Before connecting outdoor unit, thoroughly cleanse pipework of building debris,

solder etc using a suitable chemical cleansing agent.

•

Flush the system to remove chemical cleanser.

• For all packaged model systems add a combined inhibitor and anti-freeze

solution to prevent damage to the pipework and system components.

•

For split model systems the responsible installer should decide if anti-freeze

solution is necessary for each site’s conditions. Corrosion inhibitor however

should always be used.

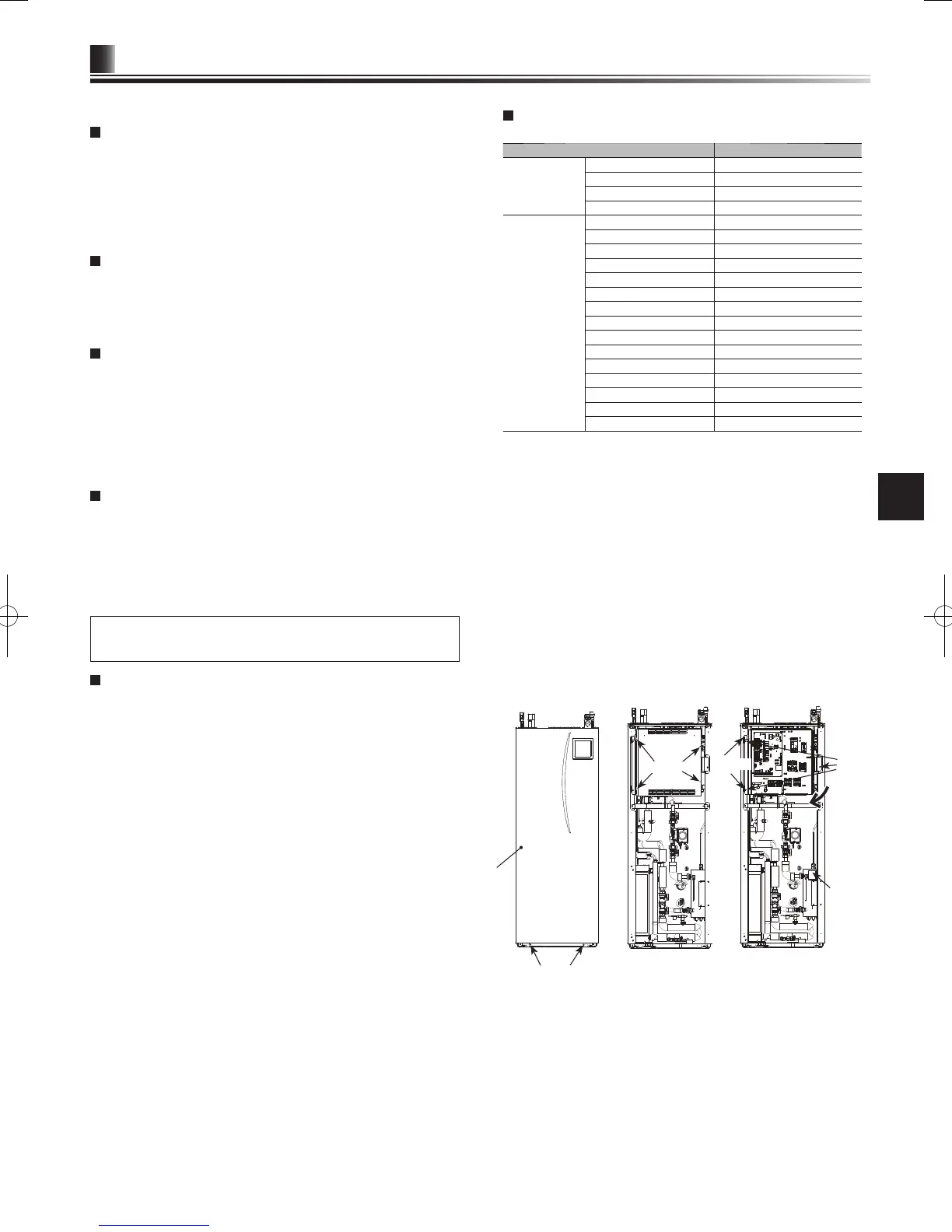

Screws

<A> <B> <C>

Front

panel

Screws

Screws

Hinges

Open

Notice/

label

<Figure 4.2.1>

Existing Installation (primary water circuit)

• Before connecting outdoor unit the existing heating circuit MUST be chemically

cleansed to remove existing debris from the heating circuit.

•

Flush the system to remove chemical cleanser.

• For all packaged model systems add a combined inhibitor and anti-freeze

solution to prevent damage to the pipework and system components.

•

For split model systems the responsible installer should decide if anti-freeze

solution is necessary for each site’s conditions. Corrosion inhibitor however

should always be used.

When using chemical cleansers and inhibitors always follow manufacturer’s

instructions and ensure the product is appropriate for the materials used in

the water circuit

How to access Internal Components and Control and

Electrical Box

<A> Opening the front panel

1. Remove the two lower screws.

2. Slide front panel upwards to slightly and open carefully.

3.

Disconnect the relay connector connecting main controller cable and the control

board cable.

<B> Opening the control and electrical box cover

1. Remove the 4 screws.

2.

Slide the control and electrical box cover upwards slightly and remove facing

panel.

<C> Accessing the back of the control and electrical box

The control and electrical box has 3 holding screws and is hinged on the left hand side.

1. Remove the holding screw on the control and electrical box.

2. The control and electrical box can then be swung forward on the left hand

hinges.

N

ote:

1. Before accessing back of control and electrical box release cables from

the tie straps attached to the cross-support.

2.

After servicing, re-secure all cables using straps provided. Reconnect

main controller cable to its relay connector. Replace front panel and re-

secure screws at base.

Loading...

Loading...