49

Service and Maintenance

7

GB

Engineers Forms

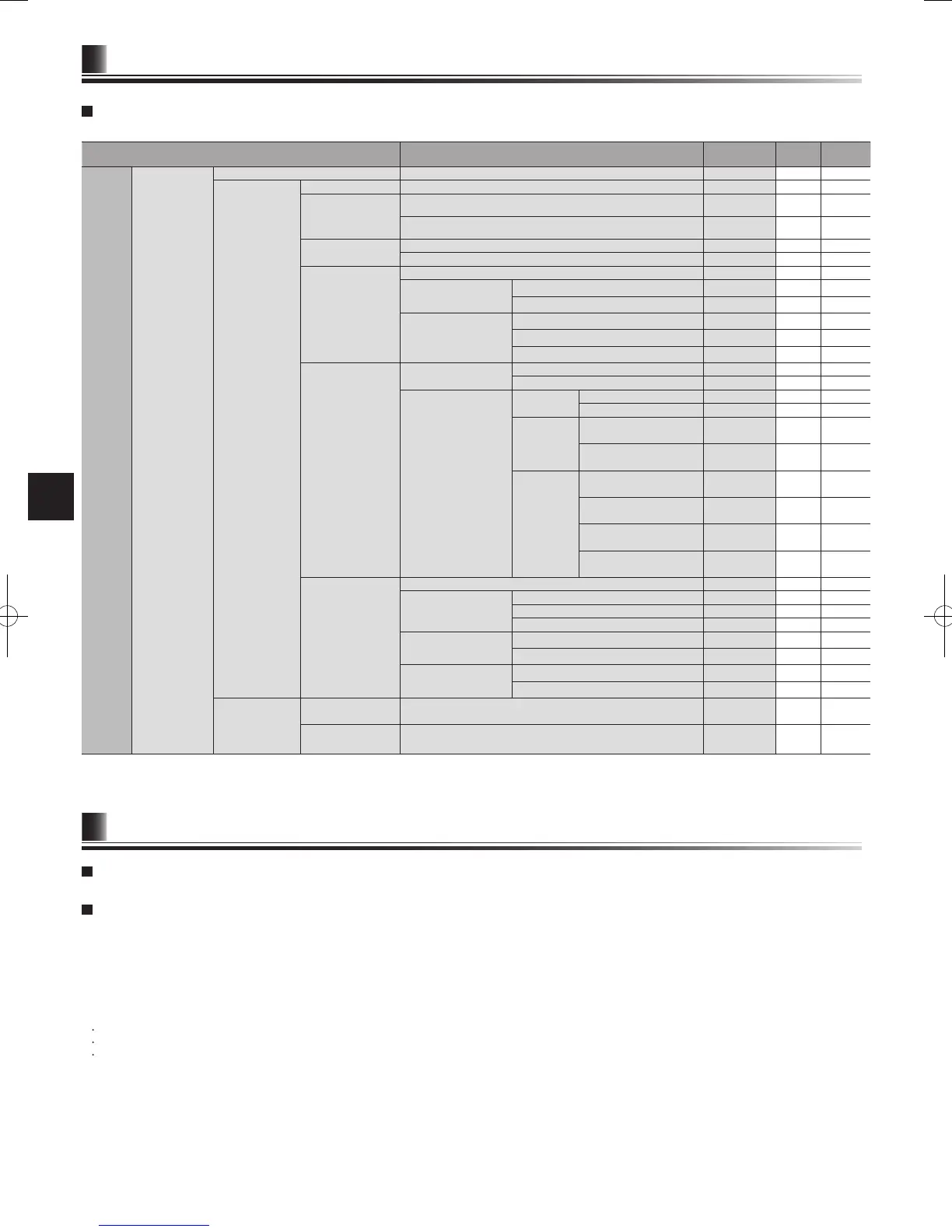

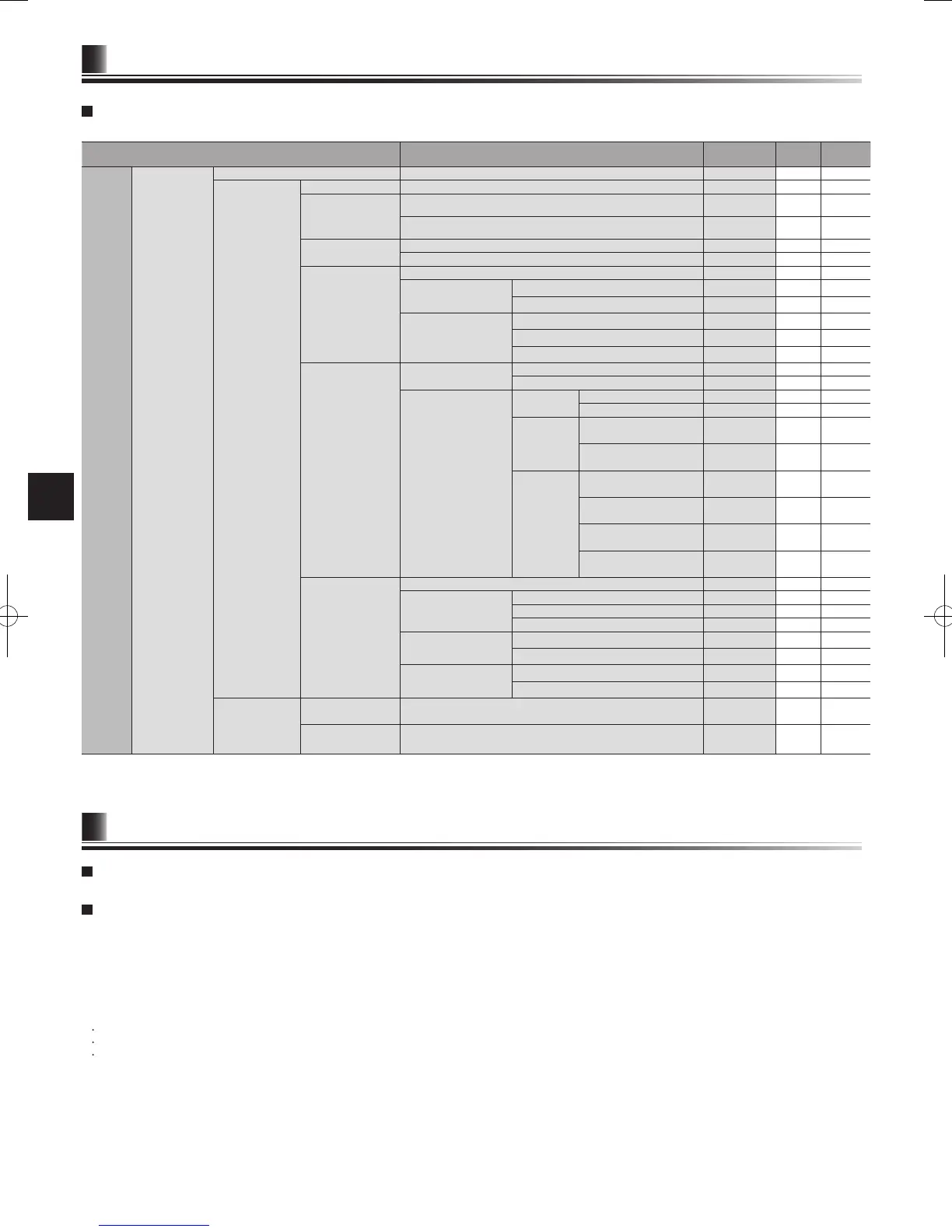

Commissioning/Field settings record sheet (continued from the previous page)

Main controller screen Parameters

Default

setting

Field

setting

Notes

Service menu Heat source setting Standard/Heater/Boiler/Hybrid *3 Standard

Operation settings

Freeze stat function Outdoor ambient temp. (3 - 20°C) 5°C

Simultaneous

operation (DHW/

Heating)

On/Off *4 Off

Outdoor ambient temp. (−15 - +10°C) −15°C

Cold weather function

On/Off *4 Off

Outdoor ambient temp. (−15 - −10°C) −15°C

Room temp control

(Heating)

Temp. control interval (10 - 60 mins) 10 mins

Flow temp. range

Min. temp. (25 - 45°C)

30°C

Max. temp. (35 - 60°C)

50°C

Heat pump thermo diff.

adjust

On/Off *4 On

Lower limit (

−

9 -

–

1°C)

−5°C

Upper limit (+3 - +5°C)

5°C

Boiler operation

Hybrid settings Outdoor ambient temp. (−15 - +10°C) −15°C

Priority mode (Ambient/Cost/CO

2)

Ambient

Intelligent settings Energy price

*5

Electricity (0.001 - 999 */kWh)

0.5

*/kWh

Boiler (0.001 - 999 */kWh)

0.5

*/kWh

CO

2

emission

Electricity

(0.001 - 999 kg -CO2/kWh)

0.5 kg -CO2/kWh

Boiler (0.001

- 999 kg

-CO2/kWh)

0.5 kg -CO2/kWh

Heat source Heat pump capacity

(1

- 40 kW)

11.2

kW

Boiler efciency

(25

- 150%)

80%

Booster heater 1 capacity

(1

- 20 kW)

2 kW

Booster heater 2 capacity

(1

- 20 kW)

4 kW

Floor dry up function

On/Off *4 Off

Target temp. Start&Finish

(25 - 60°C) 30°C

Max. temp.

(25 - 60°C) 45°C

Max. temp. period

(1 - 20 days)

5 days

Flow temp. (Increase)

Temp. increase step (+1 - +10°C) +5°C

Increase interval (1 - 7 days)

2 days

Flow temp. (Decrease)

Temp. decrease step (

−

1 -

−

10°C)

−

5°C

Decrease interval (1 - 7 days)

2 days

External input

settings

Demand control

(IN4)

Heat source OFF/Boiler operation Boiler

operation

Outdoor thermostat

(IN5)

Heater operation/Boiler operation Boiler

operation

*3 When Dip SW1-1 is set to OFF “WITHOUT Boiler” or SW2-6 is set to OFF “WITHOUT Mixing tank”, neither Boiler nor Hybrid can be selected.

*4 On: the function is active; Off: the function is inactive.

*5 “*” of “*/kwh” represents currency unit (e.g. € or £ or the like)

Refrigerant collecting (pumpdown) for split model systems only

Refer to “Refrigerant collection” in the outdoor unit installation manual or service manual.

Back-up operation of boiler

Heating operation is backed up by boiler.

For more details, refer to the installation manual of PAC-TH011HT-E.

<

Installation & System set up>

1. Set Dip-SW 1-1 to ON "With boiler" and SW2-6 to ON “With Mixing tank”.

2. Install the thermistors THWB1 (Flow temp.) and THWB2 (return temp.) *1 on the boiler circuit.

3. Connect the output wire (OUT10: Boiler operation) to the input (room thermostat input) on the boiler. *2

4. Install one of the following room temp. thermostats. *3

Wireless remote controller (option)

Room temp. thermostat (eld supply)

Main controller (remote position)

*1 The boiler temp. thermistor is an optional part.

*2 OUT10 has no voltage across it.

*3 Boiler heating is controlled on/off by the room temp. thermostat.

<

Remote controller settings>

1. Go to Service menu > Heat source setting and choose “Boiler” or “Auto”. *3

2. Go to Service menu > Operation settings > Boiler settings to make detailed settings for “Auto” above .

*3 The “Auto” automatically switches heat sources between Heat pump (and Electric heater) and boiler.

Supplementary information

8

Loading...

Loading...