11.

ADJUSTMENT

OF

NEEDLE

UP

STOP

POSITION

(LU2-410-B1T,

LU2-430-B1T)

The needle UP

stop

position,

after

thread

trimming, should be adjusted depending on

the

thicknesses

and

materials

of

threads

and

fabrics.

For

adjustment,

proceed

as

follows;

[Adjusting Procedure]

Perform stitching

and

thread

trimming

on

a sample

and

check

deviation

between

the

white

point

on

the

balance wheel

and

the

black

point

on

the

arm

when

needle

UP

motion

stops.

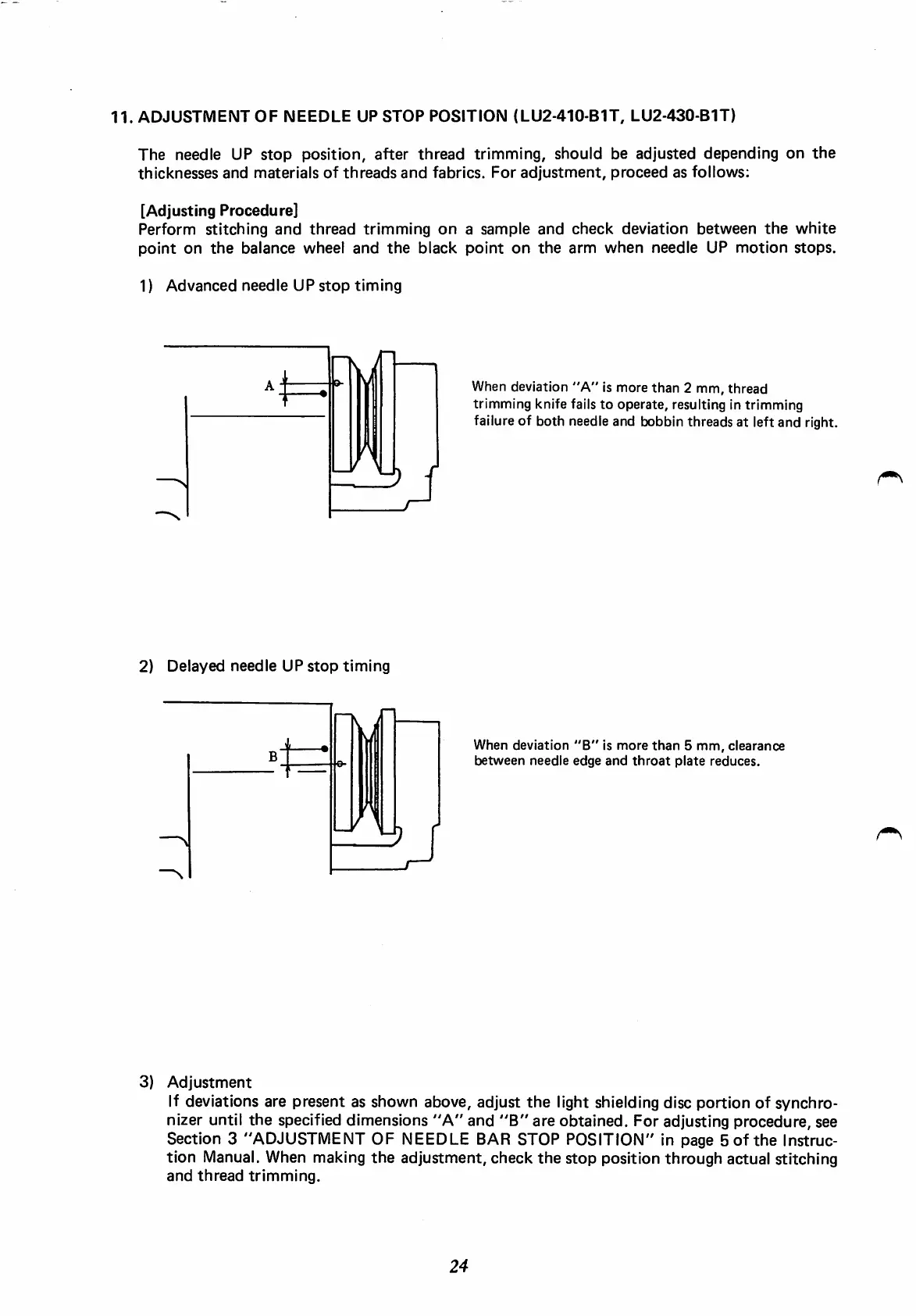

1)

Advanced

needle

UP

stop

timing

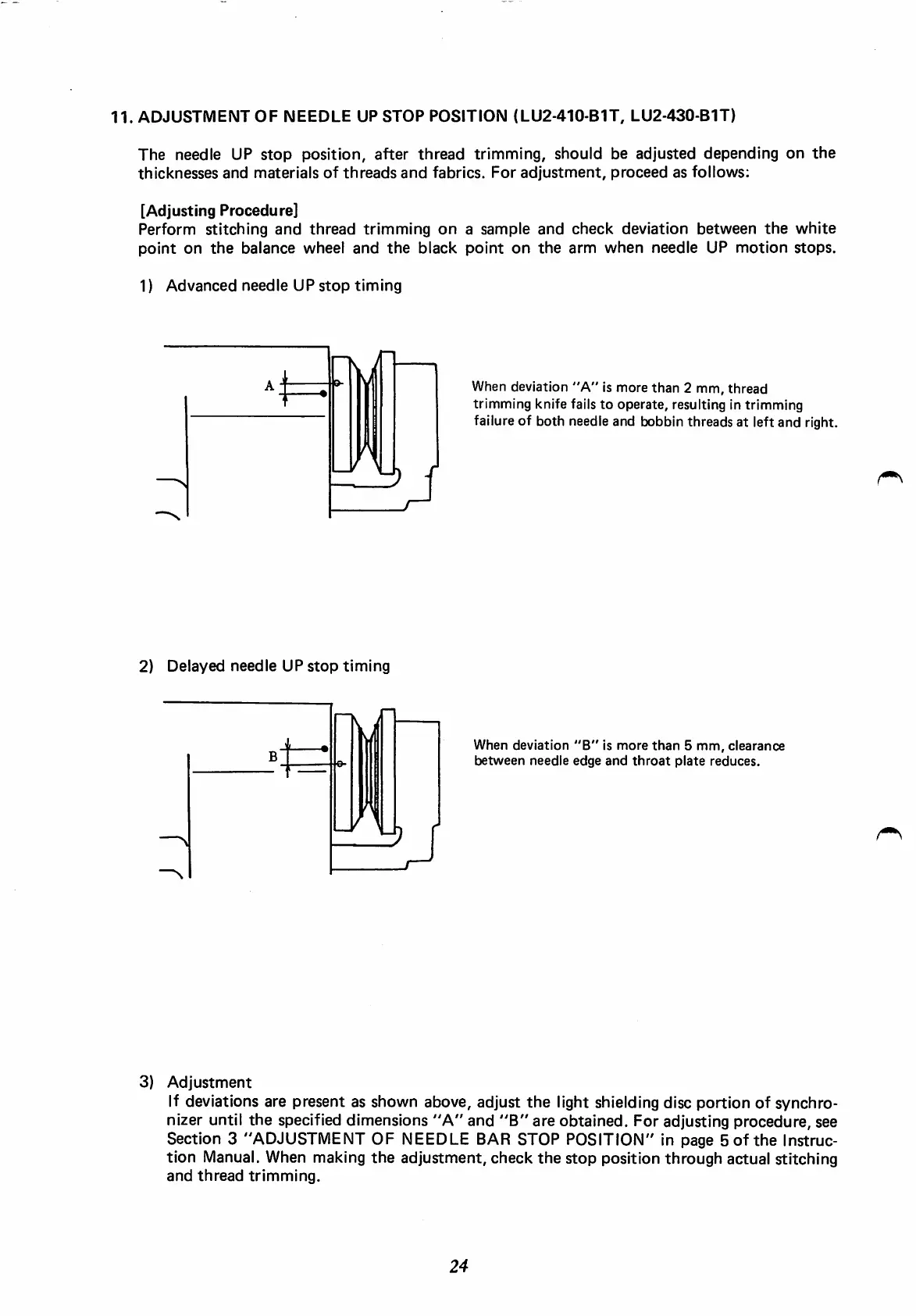

2)

Delayed

needle

UP

stop

timing

•

When deviation

"A"

is more than 2 mm, thread

trimming knife fails

to

operate, resulting in trimming

failure of both needle and bobbin threads at left and right.

When

deviation

"B"

is

more

than

5

mm,

clearance

between

needle

edge

and

throat

plate

reduces.

3)

Adjustment

If deviations are present as shown above, adjust

the

light shielding disc portion of synchro

nizer until

the

specified dimensions

"A"

and

"B"

are obtained. For adjusting procedure, see

Section 3 "ADJUSTMENT OF NEEDLE BAR STOP POSITION" in page 5

of

the

Instruc

tion Manual. When making

the

adjustment, check

the

stop position through actual stitching

and

thread

trimming.

24

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...