14. COMMUNICATION FUNCTION

14 - 4

14.2 Communication specifications

14.2.1 Outline of communication

Receiving a command, this servo amplifier returns data. The device which gives the command (e.g. personal

computer) is called a master station and the device (servo amplifier) which returns data in response to the

command is called a slave station. When fetching data successively, the master station repeatedly

commands the slave station to send data.

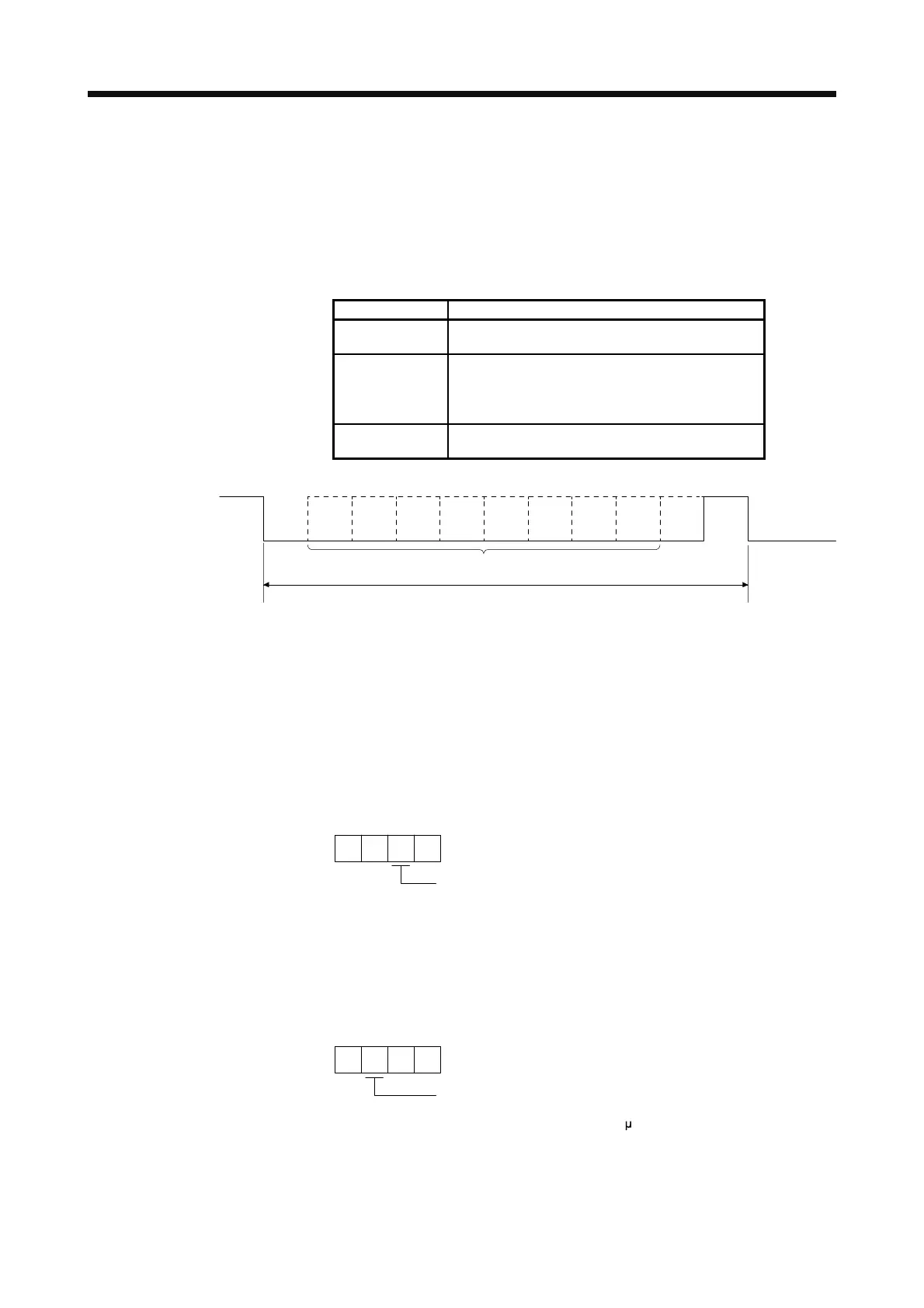

Item Definition

Baud rate [bps]

9600/19200/38400/57600/115200 asynchronous

system

Transfer code

Start bit

Data bit

Parity bit

Stop bit

1 bit

8 bits

1 bit (even)

1 bit

Transfer method

Character method Half-duplex

communication method

1 frame (11 bits)

Data

Start 0 1 2 3 4 5 6 7 Parity Stop

Next

start

(LSB) (MSB)

14.2.2 Parameter setting

When the RS-422 communication function is used to operate the servo, set the communication

specifications of the servo amplifier with the parameters.

To enable the parameter values, cycle the power after setting.

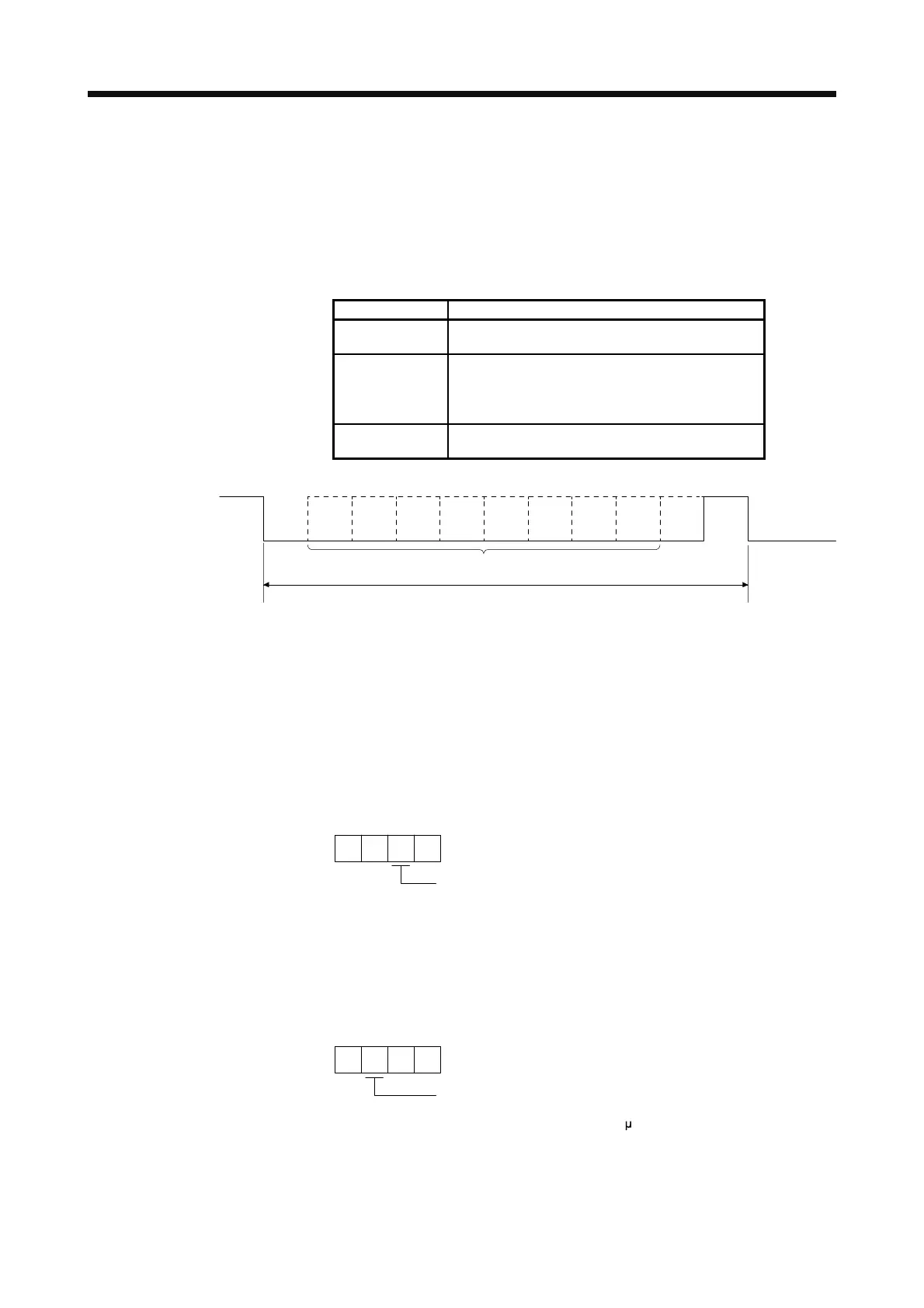

(1) Serial communication baud rate

Select the communication speed. Match this value to the communication speed of the sending end

(master station).

Serial communication baud rate

0: 9600 [bps] 3: 57600 [bps]

1: 19200 [bps] 4: 115200 [bps]

2: 38400 [bps]

[Pr. PC21]

(2) RS-422 communication response delay time

Set the time from when the servo amplifier (slave station) receives communication data to when it

returns data. Set "0" to return data in less than 800 μs or "1" to return data in 800 μs or longer.

RS-422 communication response delay time

0: Disabled

1: Enabled (responding after 800

[Pr. PC21]

s or longer delay time)

(3) Station No. setting

Set the station No. of the servo amplifier to [Pr. PC20]. The setting range is station No. 0 to 31.

Loading...

Loading...