16. USING A DIRECT DRIVE MOTOR

16 - 15

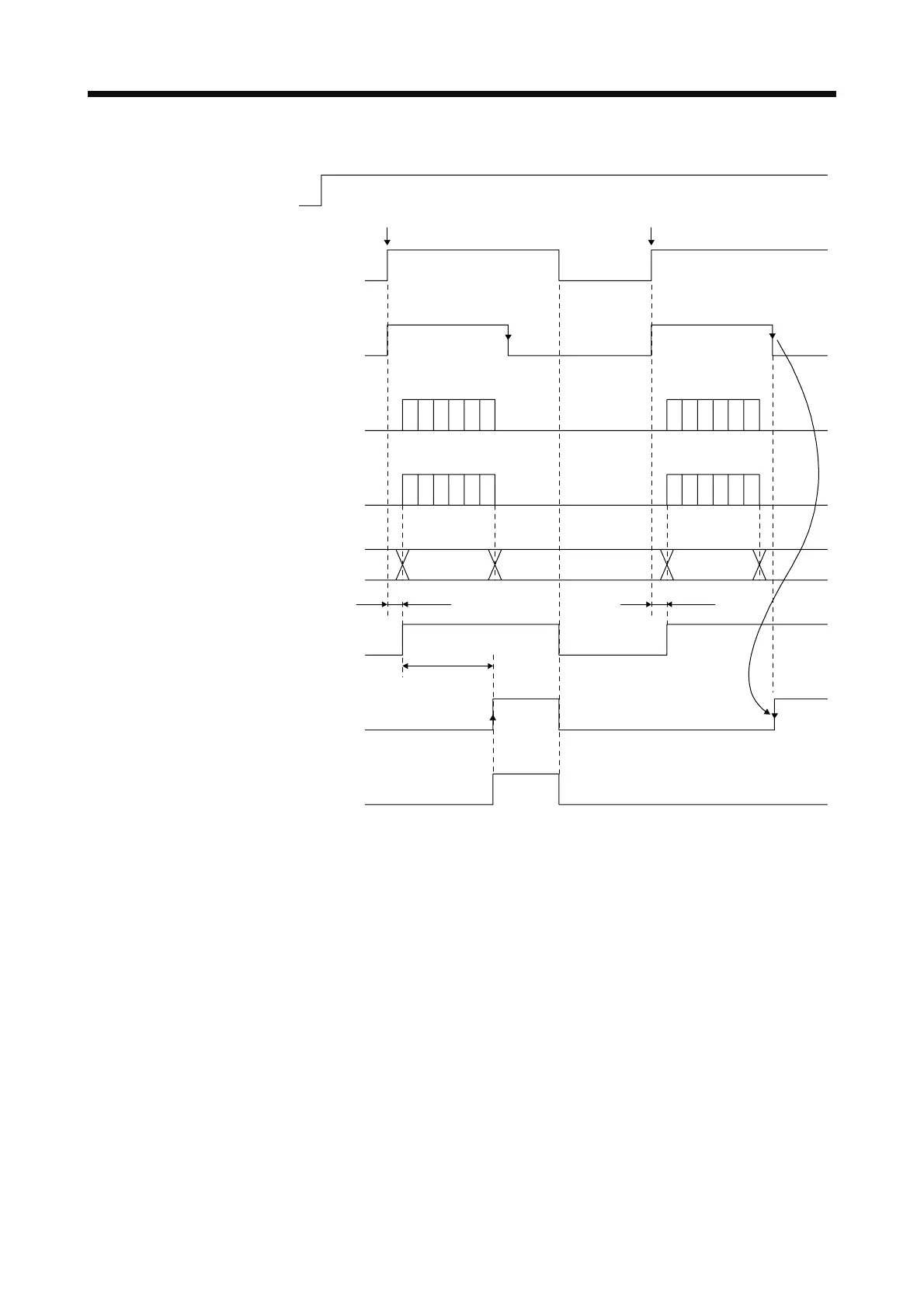

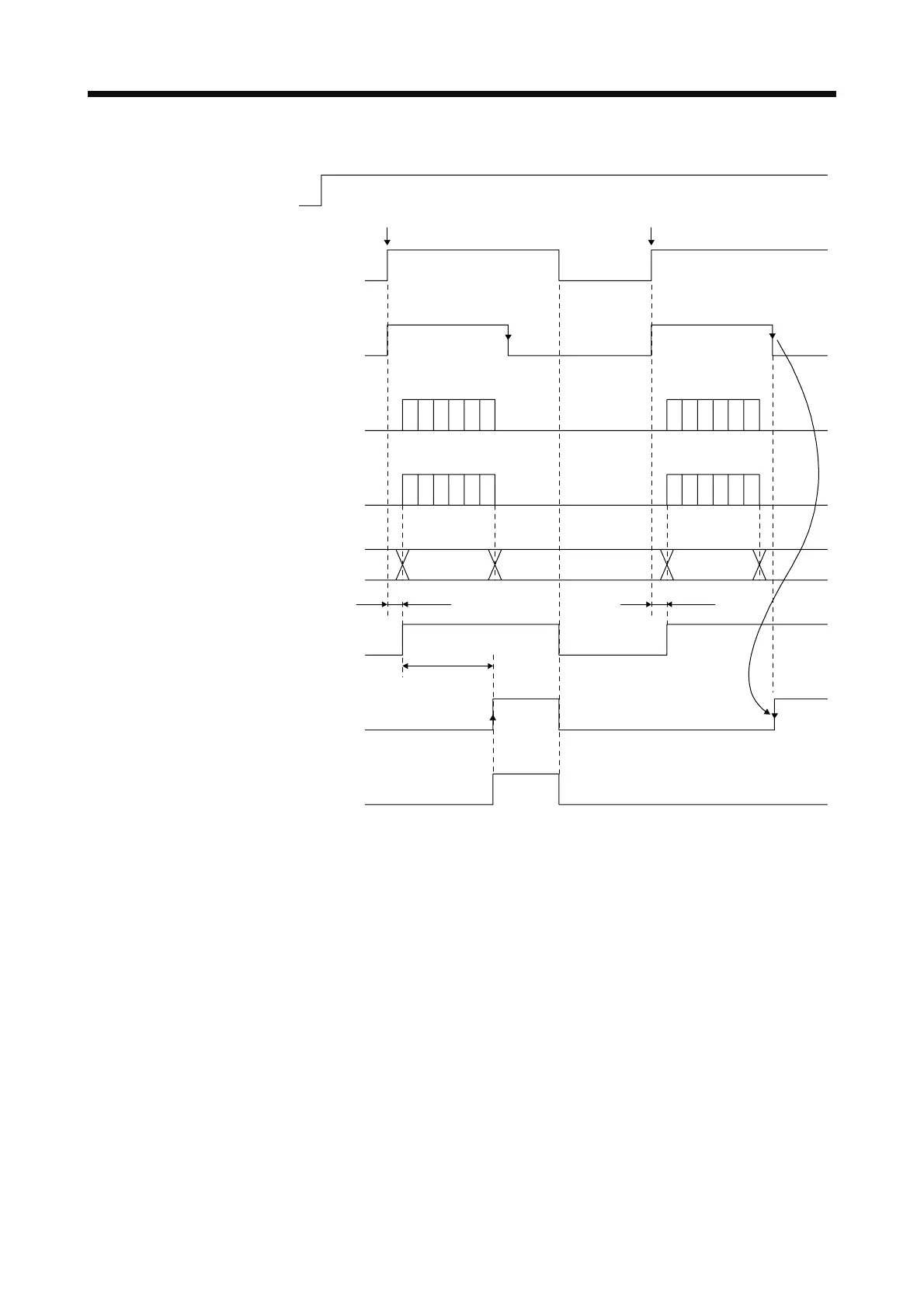

Timing chart at power on under the condition of performing magnetic pole detection

OFF

ON

Power

OFF

ON

SON (Servo-on)

OFF

ON

OFF

ON

BSR (ABS request)

OFF

ON

BST

(ABS transmission data ready)

BSB0

(ABS transmission data bit 0)

BSB1

(ABS transmission data bit 1)

OFF

ON

Base circuit

OFF

ON

RD (Ready)

Operation

possible

Operation

possible

95 ms

95 ms

Absolute

position data

Absolute

position data

During ABS transfer During ABS transfer

BSM (ABS transfer mode)

(Note 1)

(Note 1)

(Note 1)

(Note 1)

(Note 1)

(Note 1)

Warning

Second or later servo-on

First servo-on after power on

15 s or less

Magnetic pole detection time

(Note 2)

Existent

Non-existent

Note 1. Refer to section 12.8.2 (1) (b) for details.

2. Performing the magnetic pole detection triggers [AL. 93 ABS data transfer warning].

For transferring absolute position data to the controller, refer to section 12.8.

16.5 Characteristics

16.5.1 Overload protection characteristics

An electronic thermal is built in the servo amplifier to protect the servo amplifier, the direct drive motor, and

direct drive motor power wires from overloads.

[AL. 50 Overload 1] occurs if overload operation performed is above the electronic thermal protection curve

shown in fig. 16.2. [AL. 51 Overload 2] occurs if the maximum current is applied continuously for several

seconds due to machine collision, etc. Use the equipment on the left-side area of the continuous or broken

line in the graph.

For the system where the unbalanced torque occurs, such as a vertical axis system, it is recommended that

the unbalanced torque of the machine be kept at 70% or less of the motor's rated torque.

This servo amplifier has solid-state direct drive motor overload protection for each axis. (The direct drive

motor overload current (full load current) is set on the basis of 120% rated current of the servo amplifier.)

Loading...

Loading...