Do you have a question about the Mitsubishi Q Series and is the answer not in the manual?

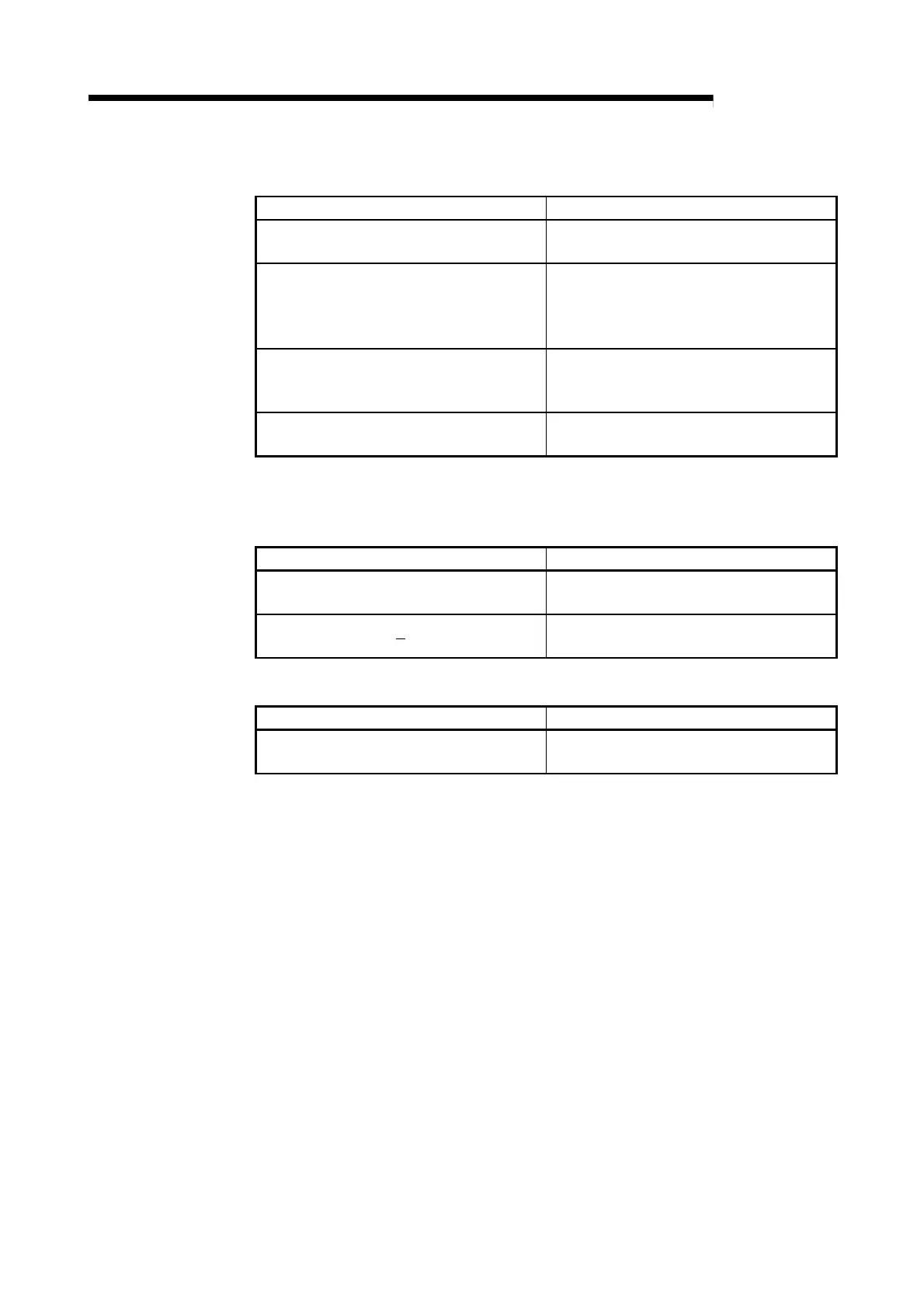

| I/O Points | Up to 4096 points |

|---|---|

| Communication | Ethernet, RS-232, RS-485 |

| I/O Modules | Digital, Analog, Specialized |

| Programming Language | Function Block Diagram, Structured Text |

| Power Supply | 24V DC, 100-240V AC |

| Operating Temperature | 0°C to 55°C |

| Shock Resistance | 147 m/s2 acceleration, 3 times in each of X, Y, and Z directions |

| Program Capacity | Up to 252K steps |

Covers safety guidelines for design, installation, and wiring to prevent hazards and malfunctions.

Safety measures for startup, maintenance, and proper disposal of the module.

Details analog I/O, input characteristics, accuracy, and conversion speed.

Explains the auto tuning function, execution procedure, and precautions.

Explains forced PID control stop and loop disconnection detection mechanisms.

Details various alert types (input, deviation) and their configuration.

Comprehensive list of buffer memory addresses, settings, and detailed error codes.

Guides for diagnosing issues based on LED indicators and specific error flags.

Step-by-step guide for module change using GX Configurator-TC or sequence program.

Important safety and operational precautions to follow before and after module change.

Comprehensive list of error codes, their causes, and processing during errors.

Guides for diagnosing issues based on RUN, ERR, and ALM LED status.

Addresses specific issues like auto tuning failures, module readiness, and alert flags.

Using GX Developer system monitor for status checks, error codes, and LED information.