Before Calling for Service Section 5

5-4

Part Number 020002777 10/11

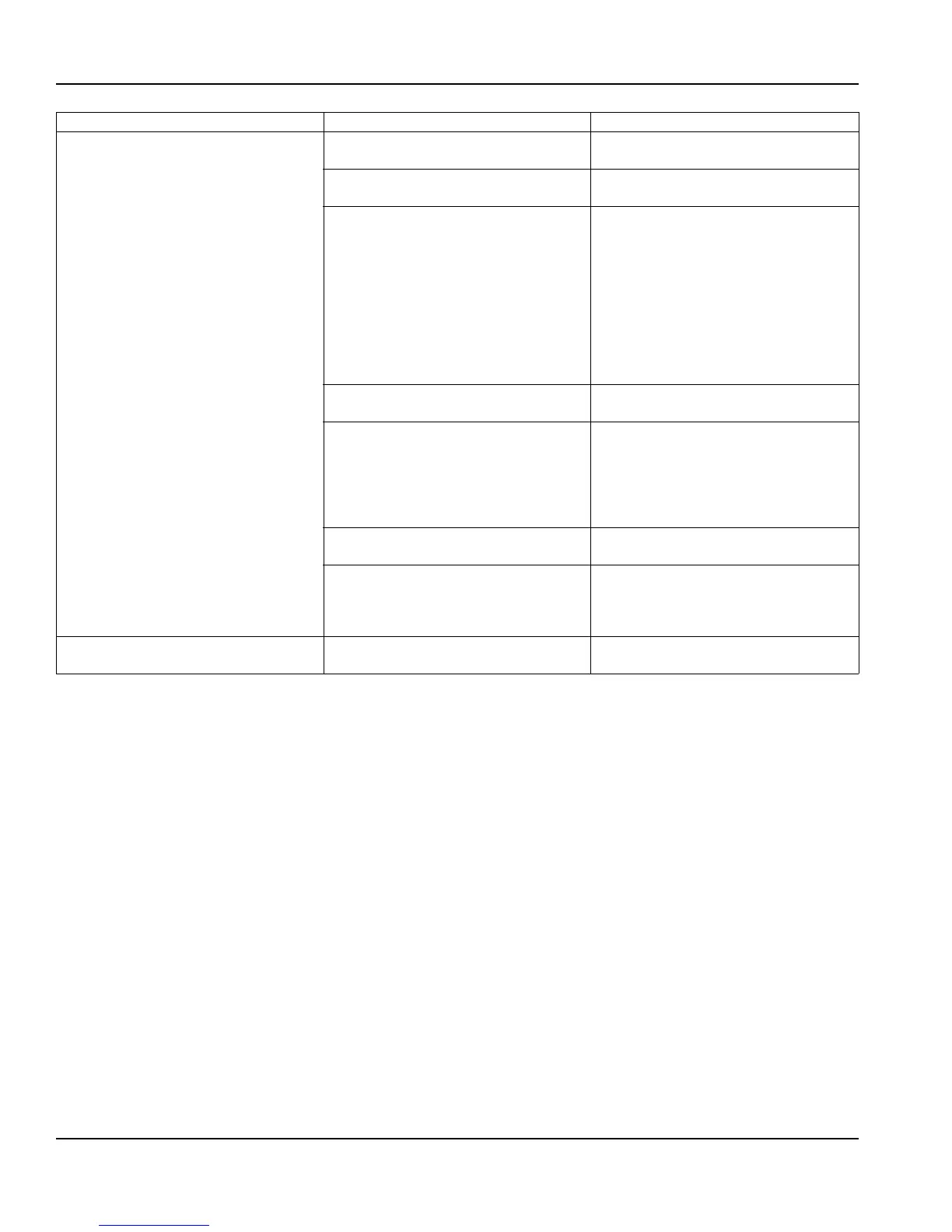

Foaming of finished products. Nozzles, Syrup Tube Diffusers dirty. Remove and clean Nozzle Assemblies and

reassemble.

Warm drinks. Refer to Troubleshooting “Section 7:

Refrigeration System” under Warm drinks.

Incorrect pressure on syrup. Verify pressure supplied to sugar base

products is at 60 psi (4.2 kg/cm2). Adjust

Medium Pressure Regulator if necessary.

Verify pressure supplied to diet product is at

15 psi (1.1 kg/cm2). Adjust Low Pressure

Regulator if necessary.

Note: Insure the Low Pressure Supply Line

has not mistakenly been switched for a

Medium Pressure Supply Line on the diet

tank.

Change-over Valve Medium or Low Pressure

is in the wrong position.

Verify valve Medium to Low Pressure is in the

Low Pressure position for diet products.

Air or CO

2 gas in syrup line. Replace empty Syrup Tank. Dispense Syrup

from valve until consistent flow is achieved

and product stabilizes. If evidence of air is still

entering line, replace Liquid Disconnect

which is allowing air to be drawn into syrup

supply.

Flake ice. Only cube ice should be used for carbonated

beverages.

Improper adjustment of valve. Insure carbonated water flow is properly set

(5 oz. in 4 seconds standard valve, 10 oz in

4 seconds Fast Flow valve). Insure Brix is

properly set. Adjust as necessary.

Unit totally inoperative; all electrical

switches in the “on” position.

Power failure, all power to system is “off”, or

Fuse/Circuit Breaker is “open”.

Check Circuit Breaker. Reset. Examine Time

Delay, replace if necessary.

Problem Possible Cause To Correct

Loading...

Loading...