2202MYJE-MY-C8-N_2018.02.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 3225**C 5.5 Reassembly

5-57

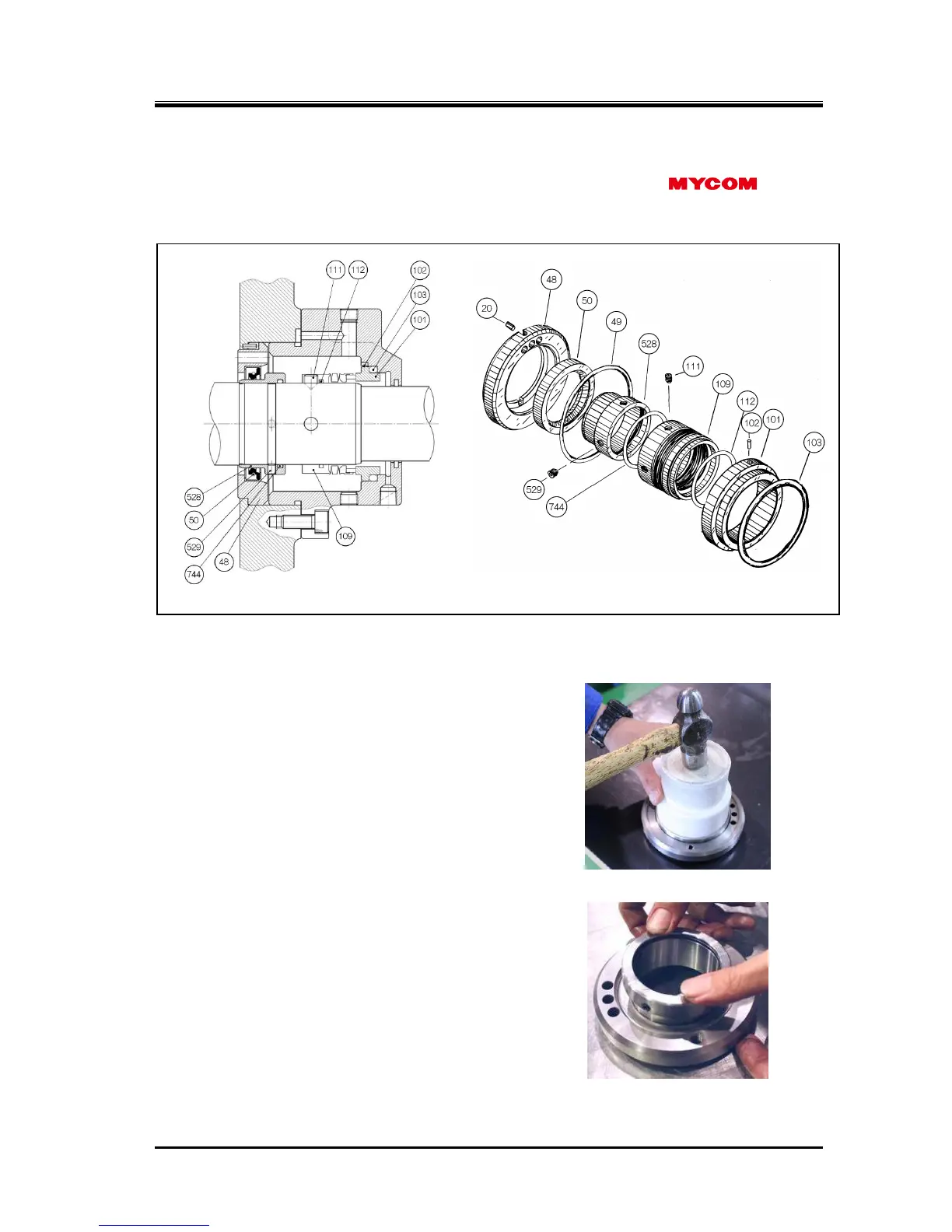

5.5.11 Shaft Seal Block

The standard mechanical seal assemblies used in the current shaft seal of standard

screw compressors are of the BBSE (balance bellows single) type. There are other cases where the

BOS (balance O-ring single) type seals are used, according to the specification by the customer.

Figure 5-18 BBSE-type Mechanical Seal

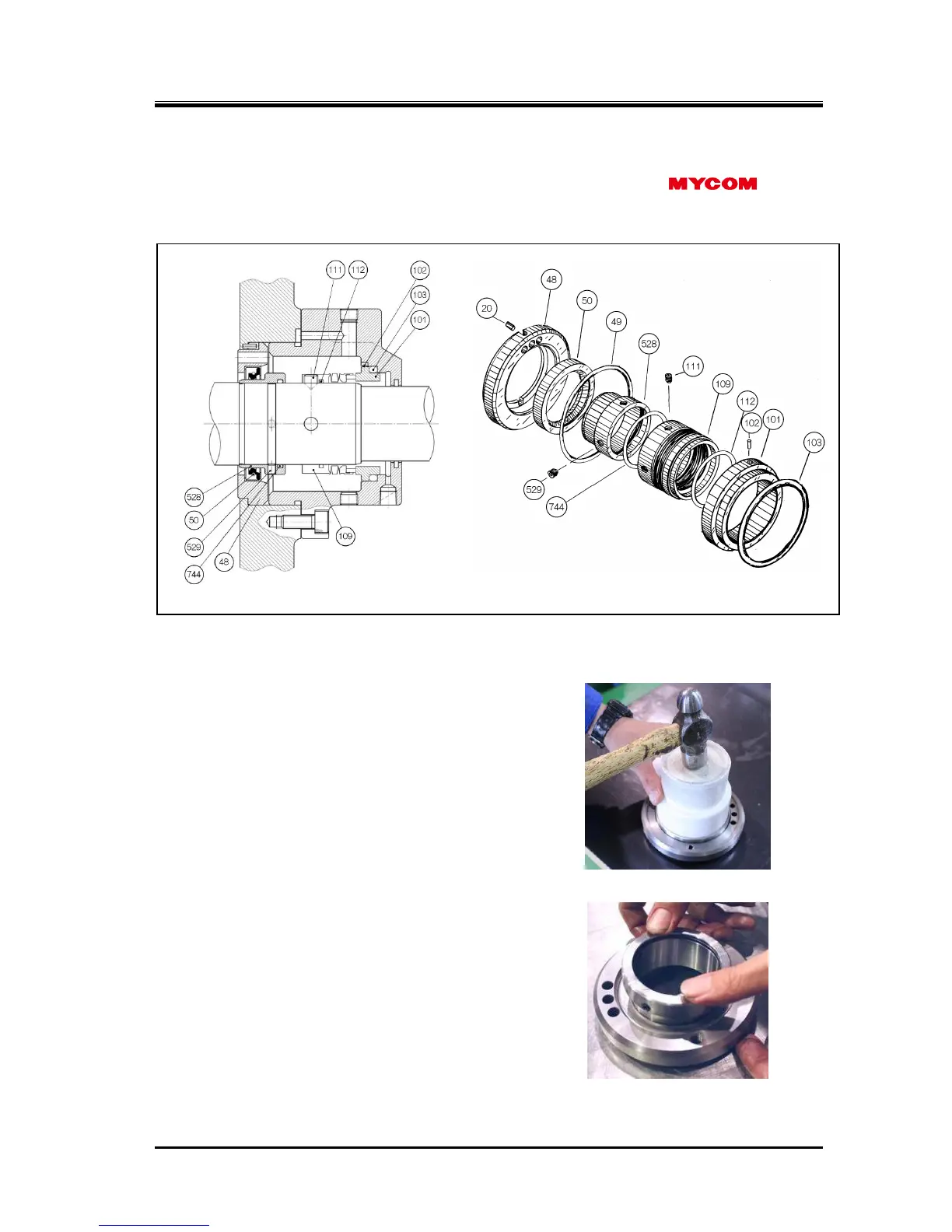

a) Before installing the mechanical seal, clean the seal

installation area on the rotor shaft. In particular,

immediately prior to the assembly, check again that

no flaw is present on the step area of the shaft where

the seal is to be installed.

b) Install the oil seal [50] on the seal retainer [48]. The

installation orientation of the oil seal has been

reversed in November 2002 as a design change.

While the oil seal had been installed with the oil seal

lip facing the direction of the atmosphere, the

direction was reversed. This is because excessively

high pressure should be avoided by helping the

escape of oil from the seal box.

Using a Teflon block or the like as a pad (Photo 105),

lightly hit the pad to push the oil seal evenly into the

retainer until it is fully seated. Once the oil seal is

fully inserted, you can easily sense it as the hitting

sound as well as the response will change.

After the installation, check that the level difference

with the retainer is uniform and that the oil seal is

evenly inserted by observing the condition from the

opposite side.

c) Insert the O-ring [744] into the inner circumference of

the oil seal sleeve [528], and install the sleeve into

the oil seal retainer with an O-ring inserted as shown

in Photo 106.

Loading...

Loading...