2202MYJE-MY-C8-N_2018.02.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 3225**C 5.4 Disassembly and Inspection

5-35

5.4.13.2 Inspection

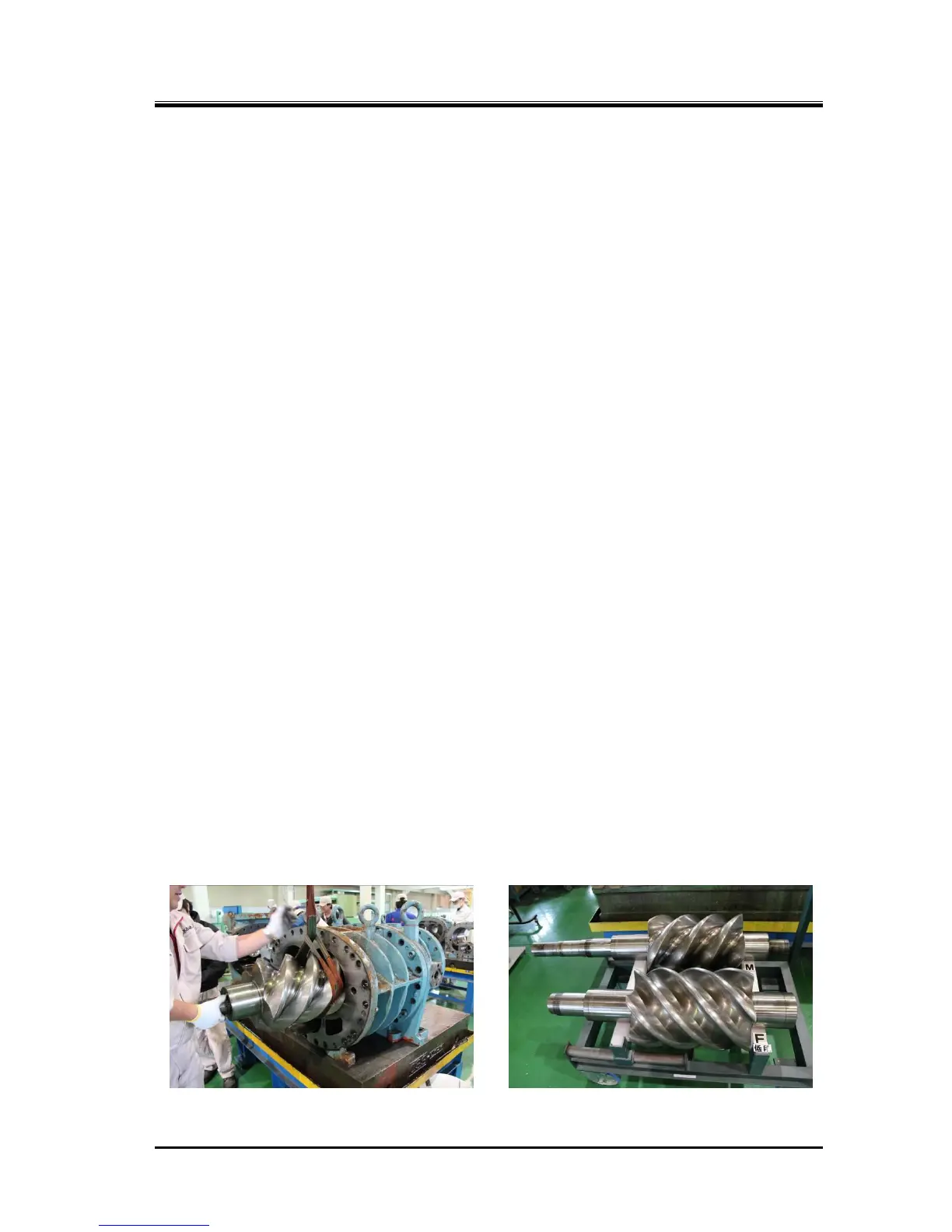

a) No abnormality should be observed on the surface of the rotor lobes under normal operations.

Regarding the contact surface of the teeth, black luster should be seen on the root area of the M

rotor lobes and on the tip area of the F rotor lobes.

In other cases, when the suction gas or oil is contaminated by fine dust, there may be fine linear

scratches on the shaft surface, in the direction perpendicular to the shaft axis. If any such flaw is

found, use a fine sandpaper or grindstone to smooth the surface.

b) In case of ammonia refrigerant or gas compressor, the non-contact surface of the rotor may be

discolored by rust or deposits. Use sandpapers or others to finish the surface according to the

degree of the problem.

c) Then, check the bearing areas of the rotor shaft. Two types of finishing are used: one is the

induction hardening (polish finishing) for the standard specification, and the other is the hard

chrome plating (polish finishing), as a special specification. The most suitable finish is selected

according to the type of refrigerant and operation conditions.

Very little wear will be present unless the compressor is operated for a long time using dirty oil or

any hard matter is buried in the metal of the inner circumference of the bearing.

d) Check the portion of the shaft on which the thrust bearing is mounted for any trace to show that the

inner race of the bearing has rotated.

If the lock nut that fastens the inner race of the thrust bearing is loosened, or if the bearing is

abnormally worn, the inner race will become rotate. If any trace of rotation is seen, correct the

problem. Depending on the degree of the rotation trace, it might be necessary to replace the rotors

with new ones.

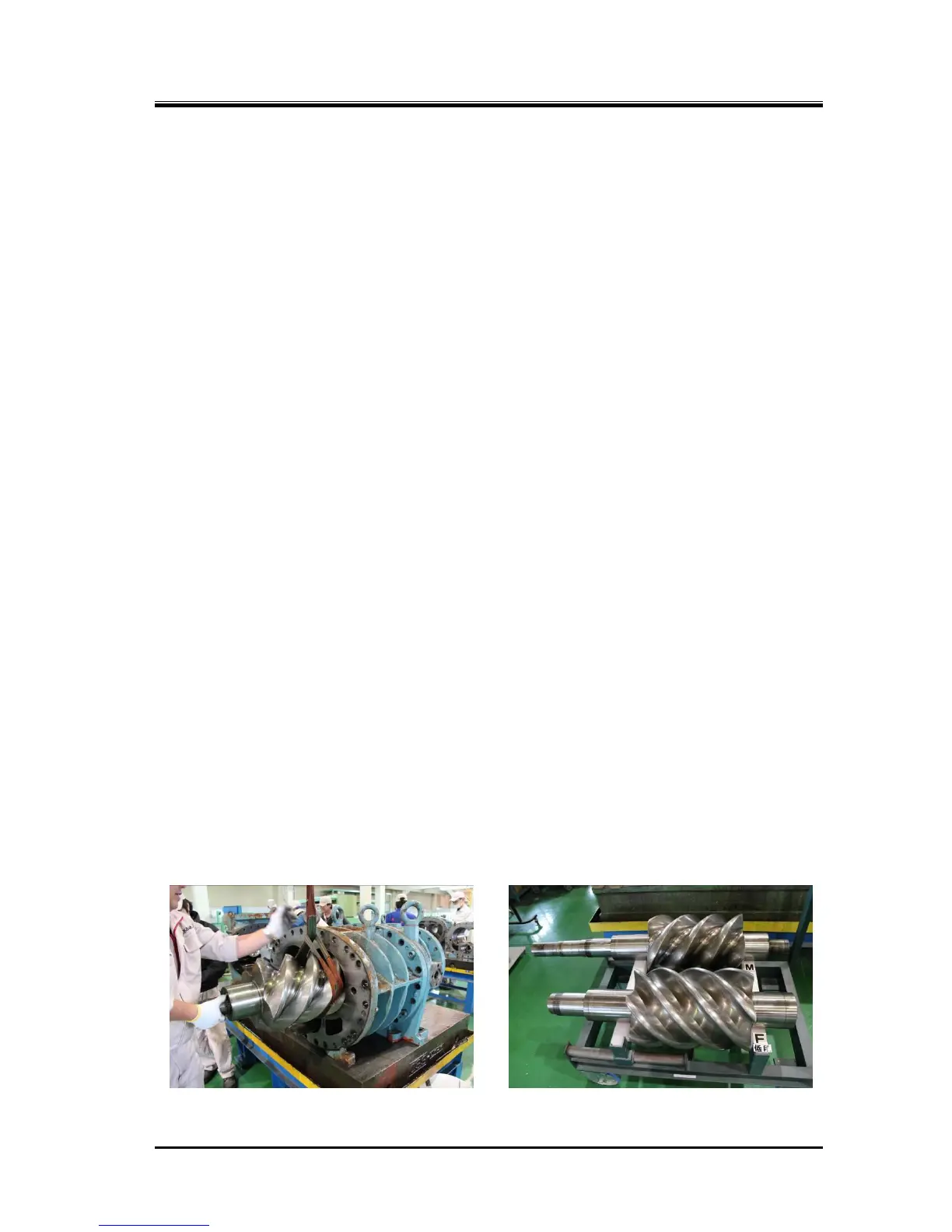

e) Check the inner surface of the main rotor casing.

There is a narrow clearance between the periphery of the rotor and the main rotor casing. Any slight

flaw present on the tip of the rotor teeth or on the inner surface of the main rotor casing, due to small

foreign matters, will not be a problem.

If there is any trace to show that the tips of the rotor teeth have hit the inner surface of the main rotor

casing, it is an abnormal condition. In such a case, the possible cause is that the main bearing

and/or side bearing is worn out. Take proper actions by finding the cause of the problem, such as

contamination of the lubricating oil or entrance of foreign matters.

5.4.14 Low-stage Rotors and Main Rotor Casing

Perform the work similarly to the case of the high-stage unit. The work should be very carefully

performed as the low-stage rotors are heavier than the high-stage rotors.

Also perform the inspection work similarly to the case of the high-stage unit.

As the low-stage M rotor is installed with a mechanical seal, do the work very carefully not to damage

the shaft. It is recommended to apply a protective tape on the shaft surface.

Loading...

Loading...